Don't hesitate to contact when you need us!

What is a CNC single-column vertical lathe used for?

2025.09.18

2025.09.18

Industry News

Industry News

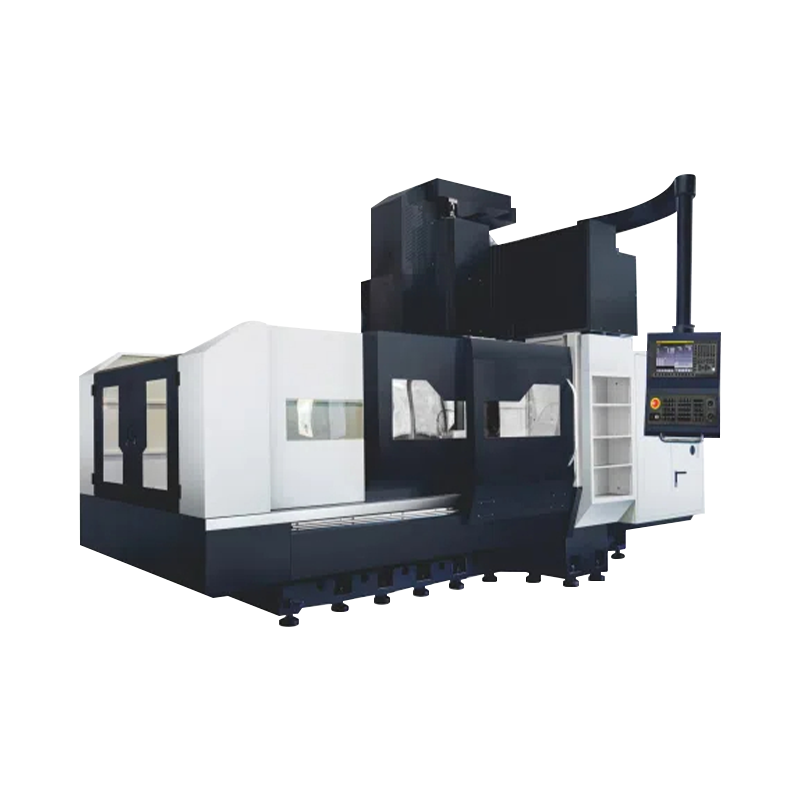

A CNC single-column vertical lathe (CNC single-column vertical lathe) is a precision machine tool specifically designed for machining large, heavy discs, rings, and short shaft parts. Its core function is to achieve high-precision, high-efficiency automated turning operations through its CNC system.

1. Core Functions and Processing Capabilities

Typical Processing Objects:

Large-diameter workpieces: Such as wind turbine flanges (diameters up to 10m or greater), gear blanks, turbine disks, and large bearing seats.

Short and Thick Parts: Workpieces with a height-to-diameter ratio of less than 1, such as hydraulic cylinder end covers and motor housings.

Complex Surfaces: CNC interpolation is used to machine special-shaped contours such as spheres and cones.

Process Coverage:

Turning: External cylindrical, facing, grooving, and threading (metric and imperial).

Complex Machining: Some models are equipped with a milling head, enabling drilling, tapping, and other operations (requires an optional Y-axis).

2.CNC Single-Column Vertical Lathe Operating Precautions

(1) Safety operation specifications

Personal protection

Protective glasses and tight-fitting work clothes must be worn. It is forbidden to operate rotating parts with gloves.

Long hair must be tied inside the cap to avoid being caught by the spindle.

Emergency stop device

Be familiar with the location of the emergency stop button (usually located on the operation panel and both sides of the machine tool). Stop immediately when encountering any abnormality.

Lifting safety

When using a bridge crane to lift heavy workpieces, ensure that the lifting device can bear a load ≥1.5 times the weight of the workpiece. Slanting is strictly prohibited.

(2) Inspection before starting the machine

Mechanical status

Check the guide rail lubricating oil level (above the oil mark center line) and confirm that there is no chip accumulation.

Manually rotate the spindle to confirm that there is no jamming (operate in the power-off state).

Tool system

Check the blade installation firmness (tighten it according to the standard with a torque wrench).

Check the turret positioning accuracy (try cutting a bar with a diameter of Φ100mm, and the roundness error is ≤0.02mm).

CNC system

Confirm that the zero point signal of each axis is normal (observe the LED indicator after returning to zero).

Check whether the program header contains safety instructions.

(3) Key points for workpiece clamping

Clip selection

Hydraulic chuck: When clamping thin-walled parts, use fan-shaped soft jaws, and the contact surface is corrected by turning (runout ≤ 0.03mm).

Special tooling: When processing eccentric workpieces, a balancing block is required to avoid spindle vibration (dynamic balancing grade G6.3).

Alignment steps

Use a dial indicator to align the end face of the workpiece (error ≤ 0.01mm/100mm). After rough alignment, use low pressure clamping (0.5MPa). After fine adjustment, increase the pressure to the rated value.

3.Maintenance points of CNC single-column vertical lathe

(1) Daily maintenance (per shift/8 hours)

cleaning work

Chip cleaning: Use a hook knife to clear the accumulated chips in the T-groove of the workbench and the guide rail protective cover to avoid scratching the guide rail.

Coolant maintenance: Check the concentration (recommended 5%-8%), the filter is free from clogging (40μm accuracy), and replenish evaporation losses in a timely manner.

Clean appearance: Wipe the operation panel and display screen with cotton cloth, and prohibit using alcohol to clean the optical ruler.

lubrication inspection

Manually inject the guide rail lubricating oil pump 3-5 times (observe whether the oil passage is smooth).

Check the oil level of the spindle oil mist lubrication system (not less than 1/3), and adjust the oil mist amount to 8-10 drops per minute.

Critical component status

Confirm that the hydraulic system pressure (usually 2.5-3MPa) and the pressure fluctuation is ≤ 0.2 MPa.

Auscultation of the running sound of the main shaft, and abnormal noise needs to be stopped for repair.

(2) Weekly maintenance

mechanical system

Guide rail and screw: After cleaning the guide rail surface with kerosene, apply ISO VG68 guide rail oil (the oil film is even and uninterrupted).

Tool tower maintenance: Remove the cutter head, clean the tapered hole, and apply a thin layer of lubricating grease.

electrical system

Check the cable drag chain for wear and tear and whether the joints are loose.

Clean the ventilation filter of the electrical control cabinet (reverse purging with compressed air).

(3) Monthly maintenance

accuracy detection

Use a laser interferometer to test the positioning accuracy (if the X-axis repeated positioning error is greater than 0.01mm, the parameter needs to be compensated).

Test the flatness of the workbench (≤0.02mm/1000mm, exceeding the tolerance requires scraping and grinding repair).

In-depth maintenance

Spindle bearing: Measure the temperature rise (check the preload force when running continuously for 2 hours. ΔT>15℃).

Cooling system: Clean the water tank and sterilize it (cycle with 1% sodium nitrate solution for 30 minutes).

lubrication system

Change the headstock gear oil (first 500 hours, subsequent every 2000 hours).

Check whether the centralized lubrication distributor is blocked (the flow difference at each oil outlet is greater than 20% and needs to be replaced).

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى