Don't hesitate to contact when you need us!

What is a Drilling and Tapping Machine?

2025.09.25

2025.09.25

Industry News

Industry News

A drilling and tapping machine is a machine tool that combines drilling and tapping functions. It is primarily used to drill holes and create internal threads (tapping) in materials such as metal, plastic, and wood. Through automated or semi-automated operation, it improves processing efficiency and precision and is widely used in machinery manufacturing, mold making, automotive repair, and electronic equipment assembly.

1. Main Functions of a Drilling and Tapping Machine

Drilling: A high-speed rotating drill bit creates a circular hole in a workpiece.

Tapping: A thread (such as standard threads like M6 and M8) is cut into the drilled hole to facilitate subsequent bolt fastening.

2. Machine Types

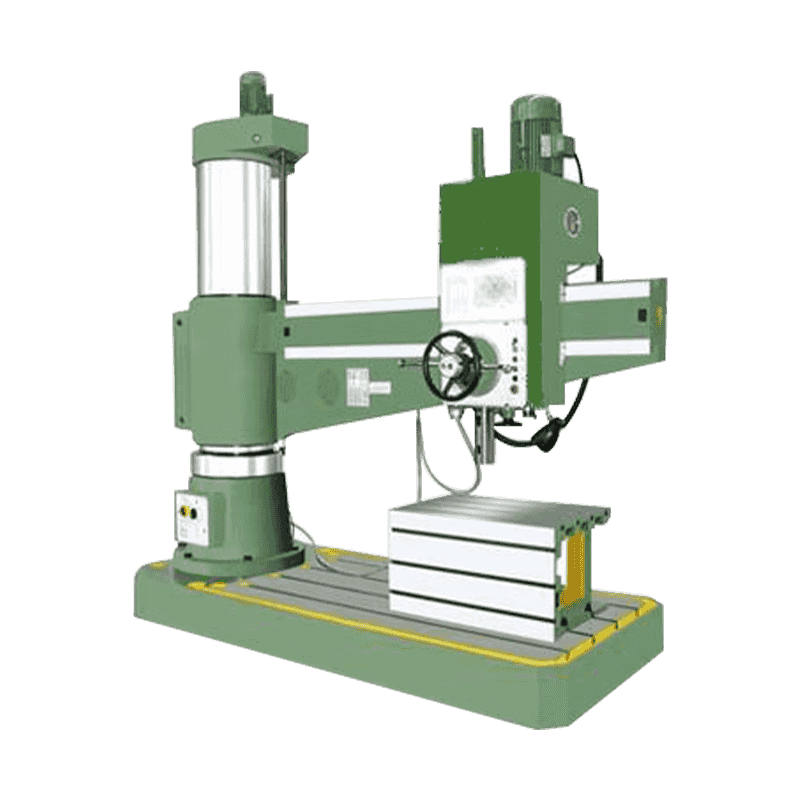

Manual Drilling and Tapping Machines

Easy to operate, with feed controlled by a handle or rocker arm, they are suitable for small batches or maintenance work.

Examples include benchtop tapping machines and handheld electric tappers.

Semi-automatic/Automatic Drilling and Tapping Machines

Driven by a motor, they automatically perform drilling and tapping, supporting preset depths and speeds, making them suitable for mass production. Examples: CNC tapping centers, pneumatic tapping machines.

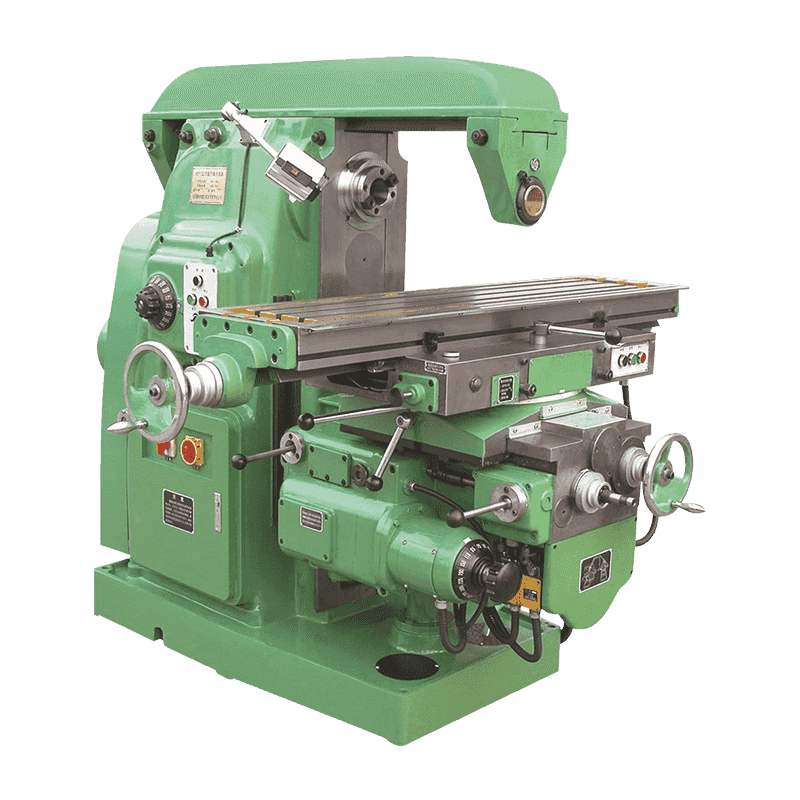

Combining milling

Drilling, and tapping functions, these machines are used for machining complex parts.

3. Core Components

Spindle: Mounts the drill or tap and provides rotational power.

Feed system: Controls the up and down movement of the tool (manual, pneumatic, or servo-driven).

Worktable: A platform that holds the workpiece and can be adjusted for angle or position.

Cooling system (optional): Spins cutting fluid to cool the tool and extend tool life.

Control system (automatic): Adjusts the speed, feed rate, and tapping depth.

4. Precautions

Tool Selection: Select drills and taps based on the material (e.g., high-speed steel, carbide). The drilling diameter should be slightly smaller than the tapping diameter (refer to the thread specification table).

Speed and Feed: Use low speeds for hard materials (e.g., steel) and high speeds for soft materials (e.g., aluminum). Tapping typically requires a lower speed than drilling. Lubrication and Cooling: When tapping, use cutting oil (such as butter or specialized tapping oil) to reduce friction and the risk of tap breakage.

Alignment and Perpendicularity: Ensure the tap is perpendicular to the hole to prevent thread skew or tap breakage.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى