Don't hesitate to contact when you need us!

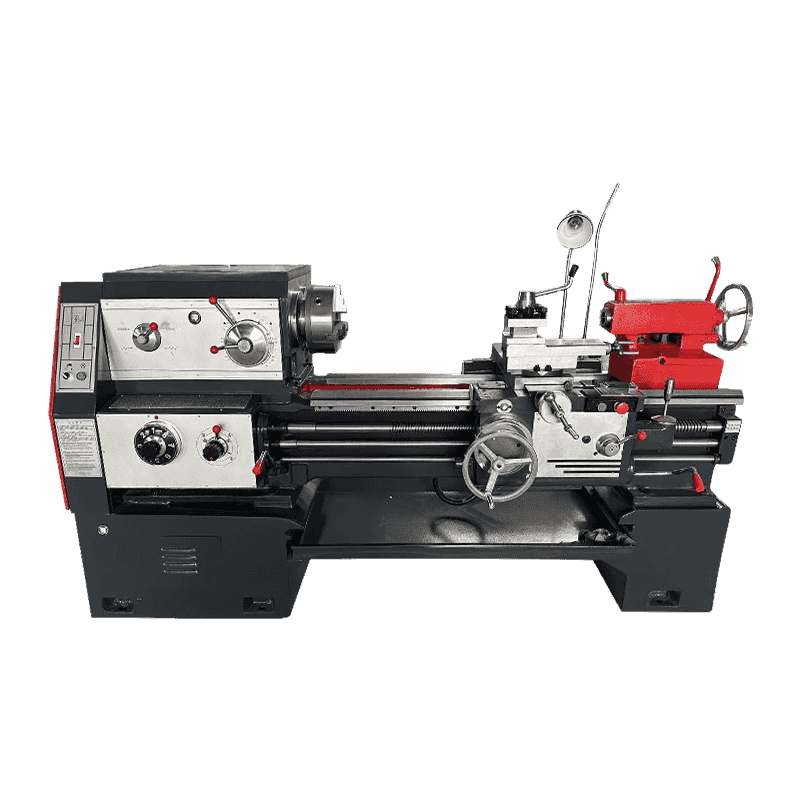

How to clean and maintain the drawout coolant tank horizontal turning center after use?

2025.04.28

2025.04.28

Industry News

Industry News

As the core system of precision machining equipment, the standardization of post-use cleaning and post-maintenance of the Drawout Coolant Tank Horizontal Turning Center directly affects the machining accuracy, tool life and overall stability of the equipment.

After completing the machining operation, the operator should first turn off the power of the equipment and wait for the coolant temperature to drop, and then start the tank emptying procedure. At this time, special attention should be paid to the sealing of the drain pipe. The use of a special splash-proof joint can reduce the splash of oil mist waste liquid. During the emptying process, it is recommended to use a high-pressure air gun to clean the inner wall of the box at the same time, focusing on flushing the guide plate joints and the back area of the filter where residual chips are easy to accumulate. For emulsified sludge with strong adhesion, a pH-neutral biological enzymatic hydrolyzer can be sprayed and left to stand for 15 minutes to reduce the mechanical cleaning intensity through catalytic decomposition.

In terms of maintenance cycle management, it is recommended to replace the coolant every 500 working hours and thoroughly clean the system. The replacement of new water-based coolants must follow the "increase in concentration" principle to avoid the imbalance of microbial ecology caused by direct replacement. Safety regulations during maintenance cannot be ignored. Operators must wear special chemical-resistant gloves and goggles to avoid skin contact with deteriorated coolants containing nitrites.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى