Don't hesitate to contact when you need us!

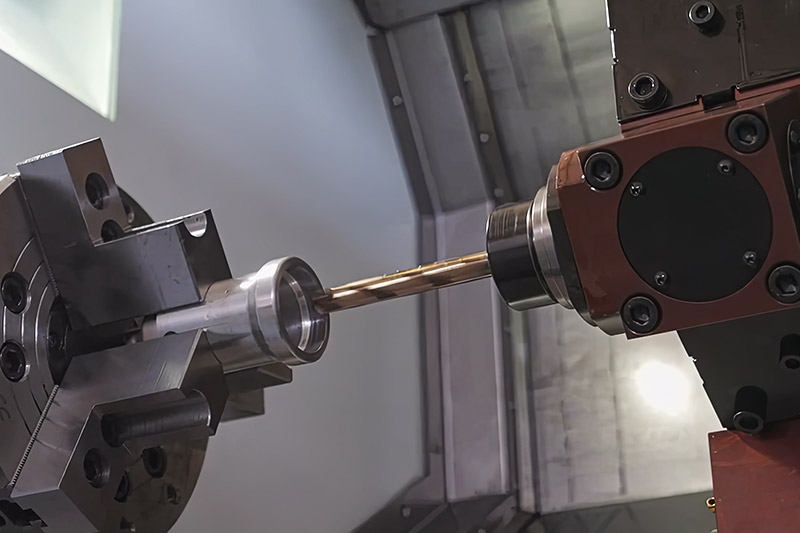

Drilling And Tapping Machines

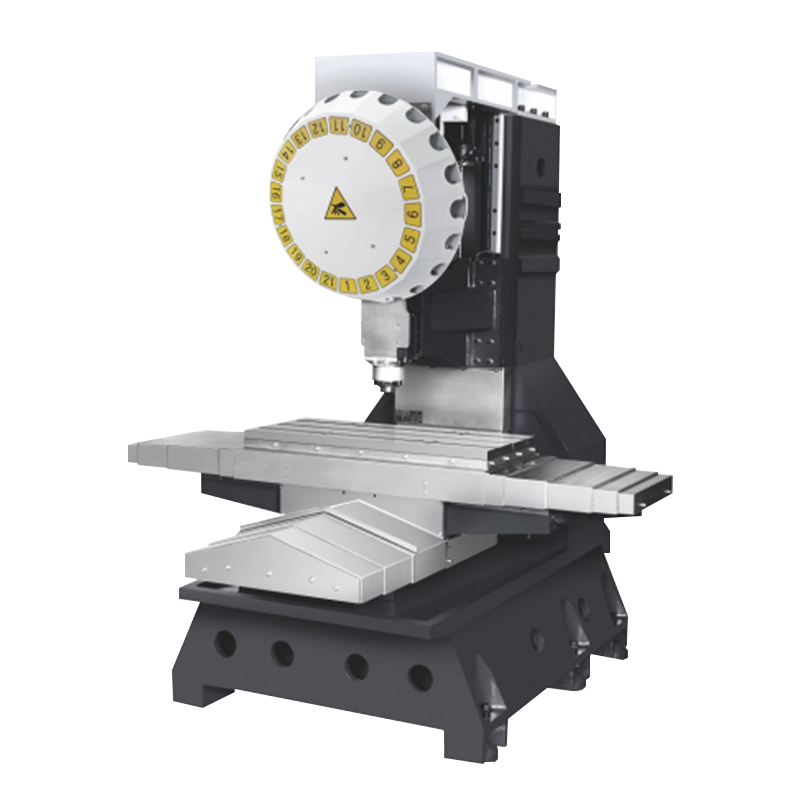

The standard configuration of the equipment includes three axes using Taiwan brand "Yintai PMMI" or "Shangyin HIVIN" C-grade ball screws, and "Yintai PMI", "Shangyin HIVVIN" or "THK" precision linear rails to ensure high precision and stability of the equipment. In addition, the three axes of the equipment are also equipped with P4-grade precision bearings to provide smoother movement and lower friction. Two specifications of 24-position tool trays, BT40-24T and BT50-24T, meet different tool requirements; as well as volumetric oil injectors to simplify the oil filling process; and adjustable height columns to adapt to different processing requirements. These configurations and options can be customized according to actual usage needs to improve the overall performance and ease of operation of the equipment.

Production Information

Main Configurations

Three axes adopt ‘Gintech PMI or Shangyin HIWIN’ or ‘THK’ C3 grade ball screws.

Three axes adopt ‘Yintai PMI or Shangyin HIWIN’ or ‘THK’ ball screws.

P4 grade bearings for three axes

‘Speedcn’ direct spindles

BT30-21T ‘Speedcn’ rotary servo tool changer.

Three-axis ‘Speedcn’ couplings

Three-axis ‘Speedcn’ cover

Volumetric oiler

Toolbox and adjustment tools

Optional Configurations

BBT30-φ110-12000/15000/20000rpm

BT30-36T ‘Speedcn’ Yi-Tai reversing type same service magazine

Technical Parameter

| Specification | unit | TP500Z | TP600Z | TP600L | TP700L | TP800V | TP1000V | T13V |

| X/Y/Z axis travel | mm | 500*400*330 | 600*400*330 | 600*450*330 | 700*450*330 | 800*500*330 | 1000*500*330 | 1300*650*450 |

| Table size | mm | 650*400 | 700*420 | 700*420 | 800*420 | 1000*500 | 1000*500 | 1400*600 |

| Table load | kg | 250 | 250 | 250 | 350 | 350 | 500 | |

| Distance from spindle center to column guideway surface | mm | 464 | 464 | 464 | 546 | 546 | 705 | |

| Distance from spindle end face to table surface | mm | 150-480 | 150-480 | 160-490 | 150-480 | 150-600 | ||

| Table T-slot (width*slot*spacing) | mm | 14T*3*125 | 14T*3*125 | 18T*5*100 | 18T*5*100 | 18T*5*100 | ||

| Spindle taper hole/diameter | / | BBT30-100 | BBT30-110 | BBT30-110 | BBT30-110 | BBT-30-110 | ||

| Spindle speed | r/min | 20000 | 20000 | 20000 | 20000 | 12000 | ||

| (XNZ) Rapid traverse | m/min | 36/48 | 36/48 | 48 | 48 | 36 | ||

| Ball screw | mm | XY:Ф28*12116 Z:Ф32*12116 | XYZ:Ф32*16 | XYZ:40*12 | ||||

| Roller guide (width of line/number of sliders) | mm | XYZ:30*2 | XYZ:30*2 | XYZ:35*2 | X:45*6 YZ:45*4 | |||

| Machine weight | kg | ≈2200 | ≈2300 | ≈2500 | ≈2550 | ≈3000 | ≈3300 | ≈4500 |

Keep in Touch

-

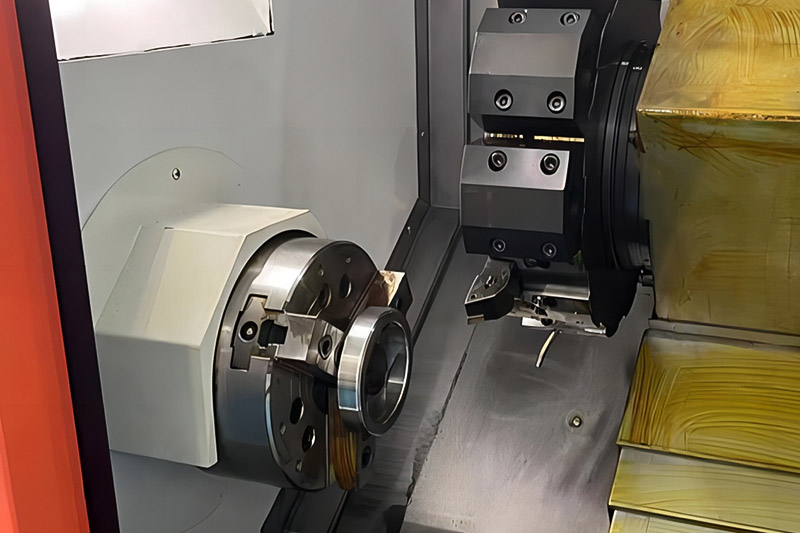

In the world of modern manufacturing, precision and efficiency are key. One of the most advanced techniques used to achieve these goals is Horizontal CNC Turning. But what exactly is Horizontal CNC Turning, and how does ...

READ MORE -

If you work in the manufacturing industry, especially in the field of precision parts machining, you have certainly encountered or at least heard of turret inclined bed CNC lathes. This equipment is very popular in the m...

READ MORE -

In the manufacturing industry, the turret inclined bed CNC lathe, as a high-precision and high-efficiency processing equipment, has become an important tool on the production lines of many enterprises. Through automated ...

READ MORE

Drilling and Tapping Machines: The Power Source of Precision Manufacturing

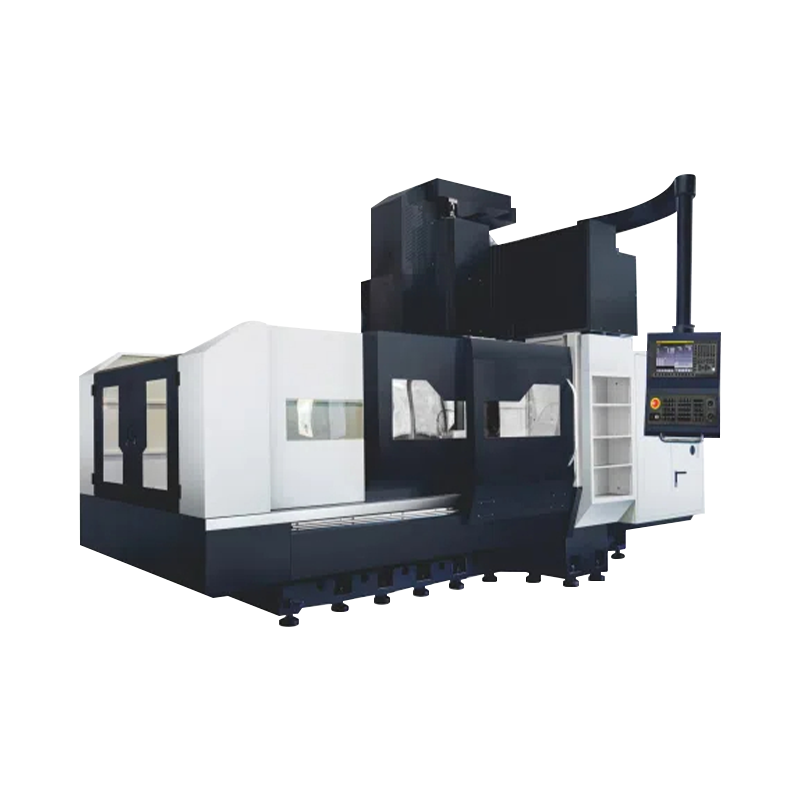

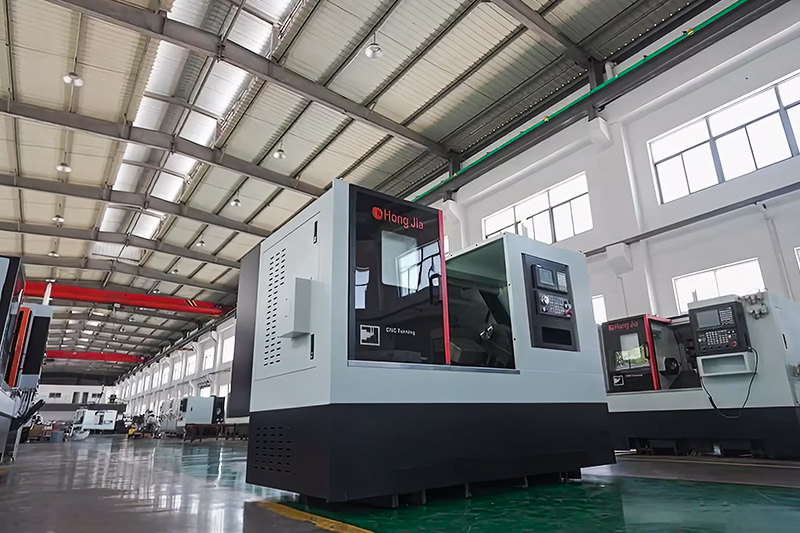

Founded in the tide of the new era, Hongjia CNC deeply understands that technological innovation is the inexhaustible driving force for the sustainable development of enterprises. The company has a research and development team composed of industry experts and senior engineers. They keep up with the international advanced technology trends, constantly break through technical barriers, and develop a series of Drilling and Tapping Machines with excellent performance and convenient operation.

Hongjia CNC's Drilling and Tapping Machines strive for the ultimate in configuration. In the standard configuration, all three axes use C-level precision ball screws from Taiwan's well-known brands "Yintai PMMI" or "Hiwin HIVIN", as well as "Yintai PMI", "Hiwin HIVVIN" or internationally renowned "THK" precision linear guides. These high-precision transmission components ensure the stability and high precision of the machine tool during operation, and can handle complex and changeable processing tasks with ease and accuracy. In addition, the three axes are equipped with P4-grade precision bearings, which further improve the smoothness of movement and reduce the friction coefficient, so that the machine tool can still maintain good processing accuracy and efficiency under long-term operation.

In order to meet the processing needs of different customers, Hongjia CNC's Drilling And Tapping Machines provide a variety of optional configurations. Among them, the 24-station tool magazine design is particularly eye-catching, providing two specifications of BT40-24T and BT50-24T, which can flexibly adapt to various tools. Whether it is small precision parts or large structural parts, you can find a suitable processing solution. This design greatly improves processing efficiency, reduces tool change time, and creates greater value for customers. At the same time, the machine tool is also equipped with a volumetric oiler, which simplifies the lubricant filling process and ensures the long-term stable operation of the machine tool.

Hongjia CNC knows that every customer's processing needs are unique. Therefore, the company not only provides standardized Drilling And Tapping Machines, but also excels in providing one-to-one customized services based on the customer's specific application scenarios. From the basic configuration of machine tools to special functional requirements, and even the personalized design of the operating interface, Hongjia CNC can flexibly adjust according to the actual needs of customers.

As intelligent manufacturing becomes the general trend of transformation and upgrading of the global manufacturing industry, Hongjia CNC is actively embracing changes with a more open attitude and constantly exploring new technological boundaries. The company not only has a place in the domestic market, but also sets its sights on the international market, striving to push the golden signboard of "Made in China" to the world stage. Through close cooperation with domestic and foreign customers, Hongjia CNC is gradually building a global service network, committed to providing customers with more efficient, intelligent and reliable metal processing solutions.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى