Don't hesitate to contact when you need us!

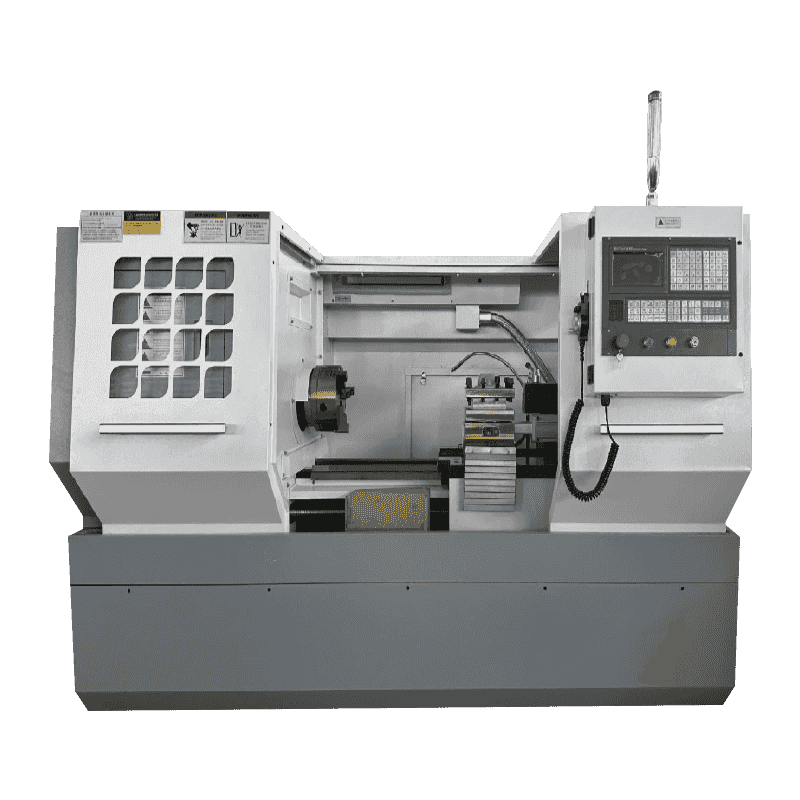

What is a Turret Inclined Bed CNC Lathe?

2026.02.13

2026.02.13

Industry News

Industry News

Content

What is a Turret Inclined Bed CNC Lathe?

A turret inclined bed CNC lathe is an advanced machining tool that offers precise control for turning operations. The inclined bed design improves chip removal and enhances machine rigidity, which results in better precision and a more stable cutting environment. The turret mechanism allows for quick tool changes, making it ideal for mass production and high-precision components.

Key Features of the Turret Inclined Bed CNC Lathe

- Inclined Bed Design: The inclined bed promotes smooth chip flow, reducing the risk of chip jamming, and improving tool life.

- Turret Toolholder: Provides efficient tool changeover, enhancing productivity by minimizing downtime.

- High Precision: CNC control ensures accurate and repeatable results for complex machining tasks.

- Automation Capabilities: Integrates with automated loading and unloading systems, allowing for unattended operation in mass production environments.

- Stability and Rigidity: The inclined bed design contributes to greater machine rigidity, enabling higher cutting speeds and better surface finish quality.

Advantages of Using a Turret Inclined Bed CNC Lathe

The turret inclined bed CNC lathe offers several advantages over traditional lathes, making it an ideal choice for various industries, including automotive, aerospace, and electronics. Here are the key benefits:

- Increased Productivity: The turret toolholder significantly reduces tool change time, allowing for faster cycle times and more efficient production.

- Enhanced Surface Finish: The improved stability of the machine results in smoother finishes on machined parts, reducing the need for secondary operations.

- Cost-Effective: The ability to perform multiple operations with minimal setup time reduces overall production costs, especially for high-volume parts.

- Flexibility: The turret inclined bed CNC lathe is versatile enough to handle a wide range of materials and part geometries.

- Improved Accuracy: The CNC control ensures tight tolerances and repeatability, which is critical for industries where precision is paramount.

Applications of the Turret Inclined Bed CNC Lathe

The turret inclined bed CNC lathe is widely used in industries that require high precision and fast production. Some of the key applications include:

- Automotive: Manufacturing precision parts such as engine components, shafts, and housings.

- Aerospace: Production of complex, high-tolerance parts for aircraft engines and structures.

- Medical Devices: Creation of parts like surgical instruments, implants, and diagnostic equipment.

- Electronics: Manufacturing of small, intricate components such as connectors and enclosures.

Common FAQs About Turret Inclined Bed CNC Lathes

- 1. How much space does a turret inclined bed CNC lathe require? These machines vary in size, but they are generally compact and can fit into standard machine shop layouts.

- 2. Is operator training necessary? Yes, due to the CNC control system, operators should be trained to ensure safe and efficient use of the machine.

- 3. What types of materials can be machined with a turret inclined bed CNC lathe? The lathe can handle a wide range of materials, including metals (steel, aluminum, titanium), plastics, and composites.

- 4. How does the turret mechanism work? The turret toolholder allows for quick switching between tools, reducing downtime during machining operations.

- 5. What are the maintenance requirements? Regular maintenance includes lubrication of moving parts, checking tool alignment, and ensuring proper calibration of the CNC system.

- 6. Can the turret inclined bed CNC lathe be used for both turning and milling? While primarily used for turning operations, some models are equipped with milling capabilities for added versatility.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى