Don't hesitate to contact when you need us!

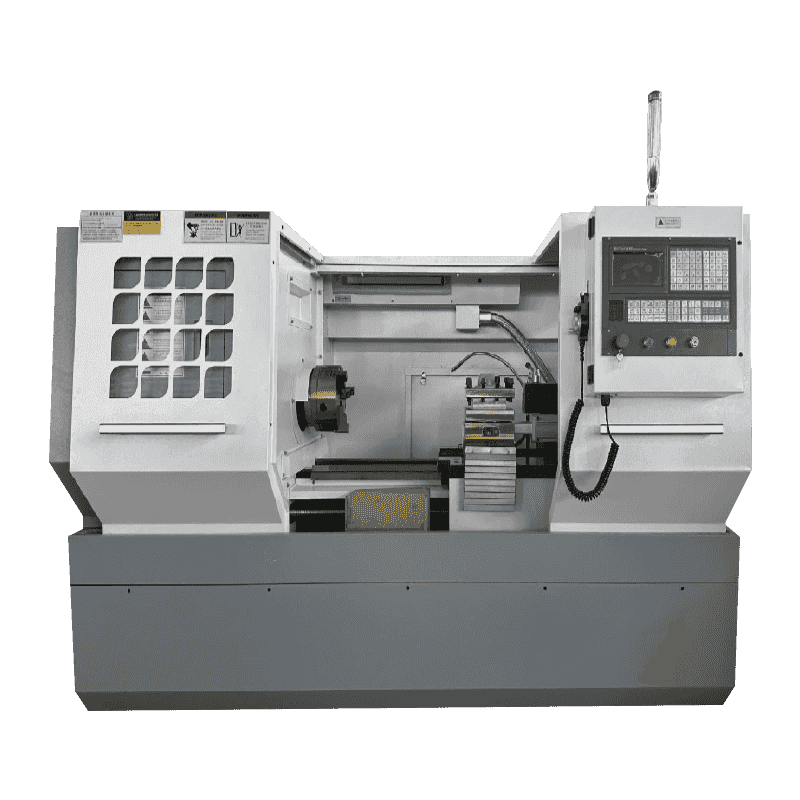

Is a Turret Inclined Bed CNC Lathe the Best Choice for High-Precision and High-Volume Turning?

2026.02.06

2026.02.06

Industry News

Industry News

Direct answer: Yes. A turret inclined bed CNC lathe significantly improves machining accuracy, chip removal efficiency, and production speed. Compared with flat-bed lathes, inclined bed structures can increase rigidity by 20%–30% and reduce non-cutting time by up to 35%, making them ideal for high-precision and mass production turning tasks.

Content

- 1 What Is a Turret Inclined Bed CNC Lathe?

- 2 Why Does the Inclined Bed Design Improve Machining Performance?

- 3 How Does the Turret System Boost Production Efficiency?

- 4 Which Industries Use Turret Inclined Bed CNC Lathes Most?

- 5 What Should You Consider When Choosing a Turret Inclined Bed CNC Lathe?

- 6 FAQ: Turret Inclined Bed CNC Lathe

What Is a Turret Inclined Bed CNC Lathe?

A turret inclined bed CNC lathe is a computer-controlled turning machine featuring an angled machine bed and an automatic tool turret. The inclined bed design allows gravity-assisted chip evacuation, while the turret enables rapid tool changes without manual intervention.

Core Structural Features

- Inclined bed structure for better chip flow

- 8–12 station tool turret for multi-process machining

- High-rigidity cast iron or polymer concrete base

- Servo-driven axes for precise positioning

This structure makes the turret inclined bed CNC lathe especially suitable for continuous production environments.

Why Does the Inclined Bed Design Improve Machining Performance?

The inclined bed layout is not just a structural upgrade — it directly impacts machining efficiency and surface quality.

Performance Advantages

- Faster chip removal reduces tool wear by 15%–25%

- Lower thermal deformation improves dimensional stability

- Improved operator ergonomics and safety

In high-speed cutting, efficient chip evacuation helps maintain consistent surface roughness, often achieving Ra ≤ 1.6 μm on standard steel components.

How Does the Turret System Boost Production Efficiency?

The automatic turret system is one of the most valuable features of a turret inclined bed CNC lathe. It enables fast tool indexing and multi-step machining in a single setup.

Turret Benefits

- Tool change time reduced to 0.2–0.5 seconds

- Multiple operations completed in one clamping

- Higher repeatability and positioning accuracy

For mass production lines, turret lathes can increase output by 30%–40% compared with manual tool-change machines.

Which Industries Use Turret Inclined Bed CNC Lathes Most?

The versatility of turret inclined bed CNC lathes makes them widely adopted across multiple manufacturing sectors.

| Industry | Typical Parts | Key Benefit |

|---|---|---|

| Automotive | Shafts, hubs | High-volume consistency |

| Aerospace | Precision connectors | Tight tolerance control |

| Hydraulics | Valve bodies | Stable surface finish |

What Should You Consider When Choosing a Turret Inclined Bed CNC Lathe?

Selecting the right turret inclined bed CNC lathe requires balancing performance requirements and production scale.

- Spindle speed and power output

- Turret capacity and tooling compatibility

- Control system (Fanuc, Siemens, or equivalent)

- After-sales support and spare parts availability

For heavy-duty cutting, choosing a spindle motor above 11 kW is recommended to maintain stable torque output.

FAQ: Turret Inclined Bed CNC Lathe

Is a turret inclined bed CNC lathe better than a flat bed lathe?

Yes. Inclined bed lathes offer better chip evacuation, higher rigidity, and improved automation, making them more suitable for high-speed and high-precision production.

What accuracy can a turret inclined bed CNC lathe achieve?

High-end models typically achieve positioning accuracy of ±0.005 mm and repeatability within ±0.003 mm.

Can this type of CNC lathe support automation systems?

Yes. Turret inclined bed CNC lathes can be integrated with bar feeders, robotic arms, and automatic loading systems to build smart production lines.

What maintenance is required?

Routine lubrication, alignment checks, coolant system cleaning, and turret calibration help maintain long-term accuracy and machine lifespan.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى