Don't hesitate to contact when you need us!

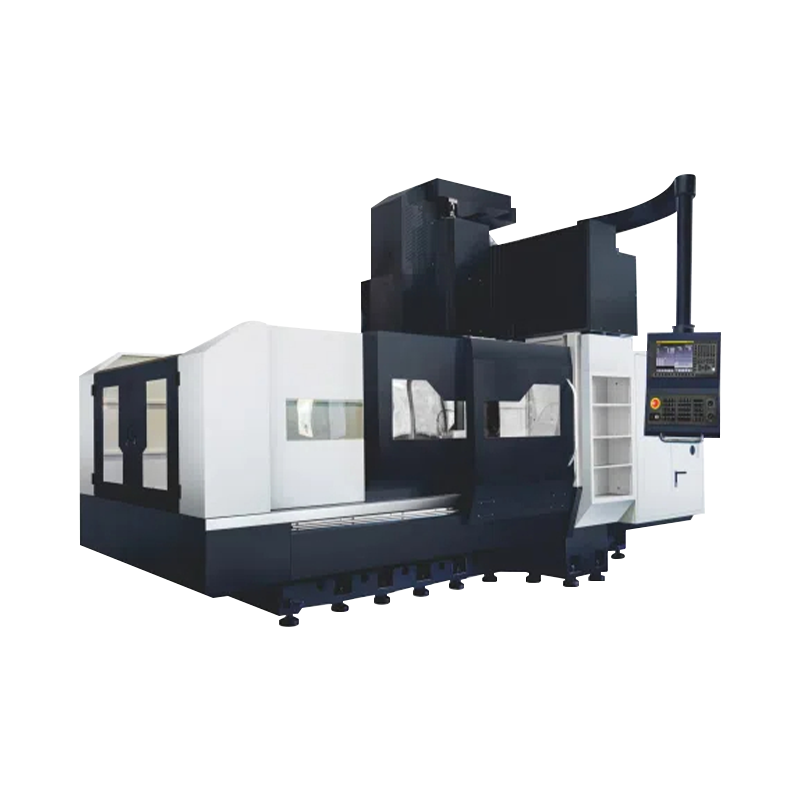

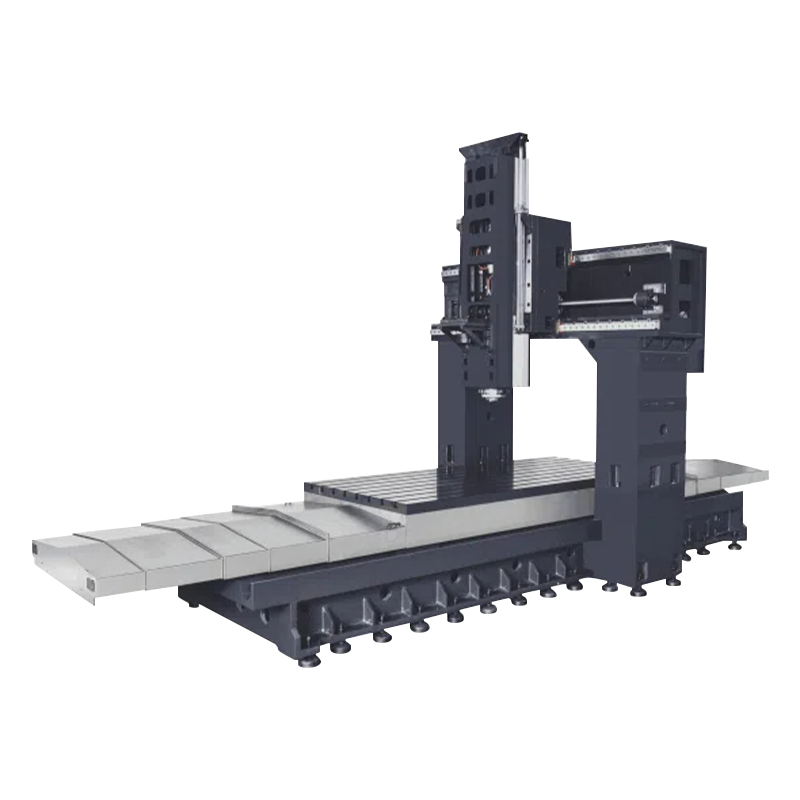

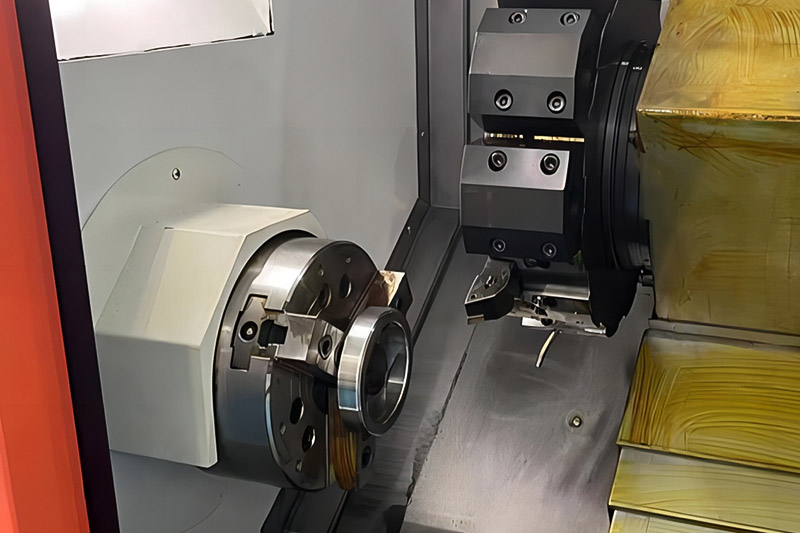

Double Column Machining Centre

Drilling and tapping machines use high-quality configurations, such as ‘Gintech PMI’, ‘Shangyin HIWIN’ or ‘THK’ C3-grade ball screws, P4-grade bearings, ‘Speedcn’ direct drive spindles and BT30-21T rotary servo tool changers, ensuring stability and high-precision processing results. Its optional configurations such as high-speed BBT30 spindles and larger tool magazines make the machines more handy when handling efficient and precise drilling and tapping tasks. Coupled with full-axis protective covers, automatic lubrication systems and quick tool change functions, drilling and tapping machines not only improve production efficiency, but also extend the service life of the equipment.

Production Information

Main configurations

| Configuration | Optional Configurations | |

| Three axes adopt Taiwan-made ‘Yintai PMMI or Shangyin HIVIN’ class C ball screws. | X to steel plate shroud, Y axis organ shroud | BT40-24T disc magazines |

| Three axes adopt Taiwan-made ‘Yintai PMI or Shangyin HIVVIN’ or ‘THK’ precision wire rails. | Volumetric oil filler | BT50-24T disc magazine |

| P4 grade bearings for three axes | Column height |

Technical parameters

| Specification | Unit | KS1210 | KS1510 | K1613L | KS1612 | KS2012 |

| X/Y/Z travel | mm | 1200*1000*500 | 1500*1000*500 | 1600*1300*600 | 1600*1200*500 | 2000*1200*500 |

| Table size | mm | 1300*900 | 1600*900 | 1700*1200 | 1700*1000 | 2100*1000 |

| Table T-slot size | mm | 5-18*165 | 5-18-165 | 7-22-150 | 6-22-160 | 6-22*160 |

| Table Load | T | 2 | 2.5 | 3 | 2 | 3 |

| Gantry width | mm | 1050 | 1050 | 1400 | 1200 | 1200 |

| Table to the bottom of the column | mm | 770 | 770 | 870 | 750 | 750 |

| Z-axis counterweight | / | Option: Nitrogen counterweight | Option: Nitrogen counterweight | Option: Nitrogen counterweight | Option: Nitrogen counterweight | Option: Nitrogen counterweight |

| Spindle specification | / | Option:BBT40-150-12000/BBT40-medium 150-15000/HSK63-15000 | ||||

| Spindle transmission method | / | Direct connection | ||||

| Rail specification (width/number of slides) | / | XY roller 45*4/Z roller 45*6 | X:Roller 45*6/Y:Roller 45*4/Z:Roller 45*6 | XY:45 ball, X:R50*16 Y:R40*12,Z:R40*10 | Y-axis 45#gon beads. | |

| Screw specification | mm | XYZ: R40*10 | X: R50*10/YZ: R40*10 | XYZ: R50*10 | X:R50*16 Y:R40*12, Z:R40*10 | X:R50*16, Y:R40*12 Z:R40*10 |

| Optical machine weight | T | 7.2 | 8.2 | 11 | 7 | 8.5 |

| Three-axis servo coupling method | / | Direct type | Direct type | Direct type | Direct type | Direct type |

| Rapid traverse | m/min | X:15/YZ: 18 | X:10/YZ: 18 | X:15/YZ: 18 | XYZ:20 | X20/YZ:20 |

| Three-axis servo reduction ratio | / | 1 :1 | 1 :1 | 1 :1 | 1 :1 | 1 :1 |

| Recommended torque | N.M | XYZ: 22.5 | X: 28.4/YZ: 22.5 | X:28.4/YZ:22.5 | XYZ:22 | X:37/YZ:22 |

| Distance from spindle nose to table | mm | 200-700 | 200-700 | 200-800 | 180-680 | 180-680 |

| Dimension of optical machine | mm | 3050*2100*2700 | 3650*2100*2700 | 4150*2550*2850 | 4050*2250*2700 | 5250*2250*2700 |

Keep in Touch

-

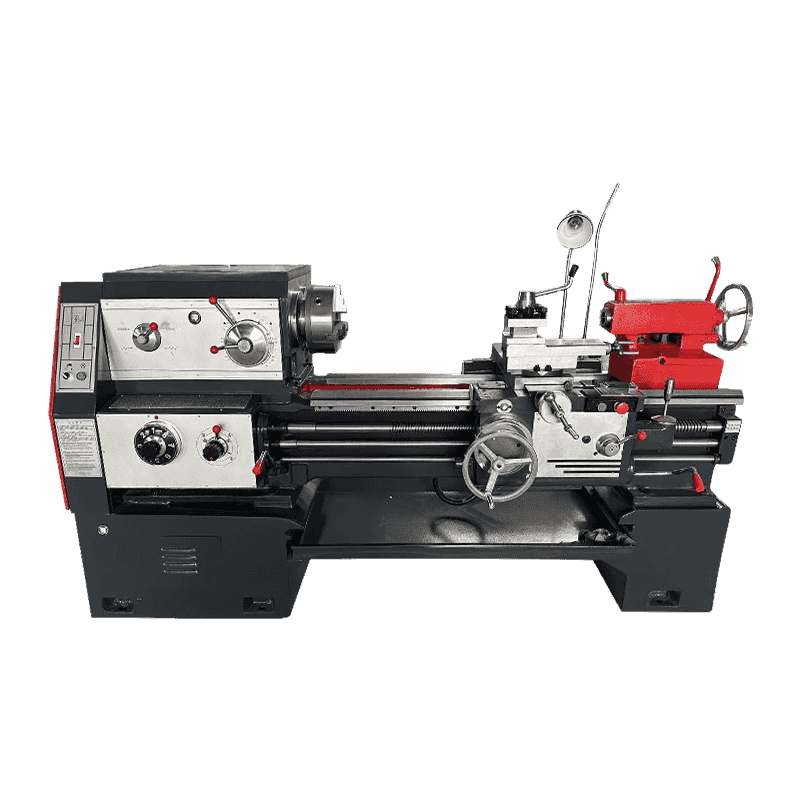

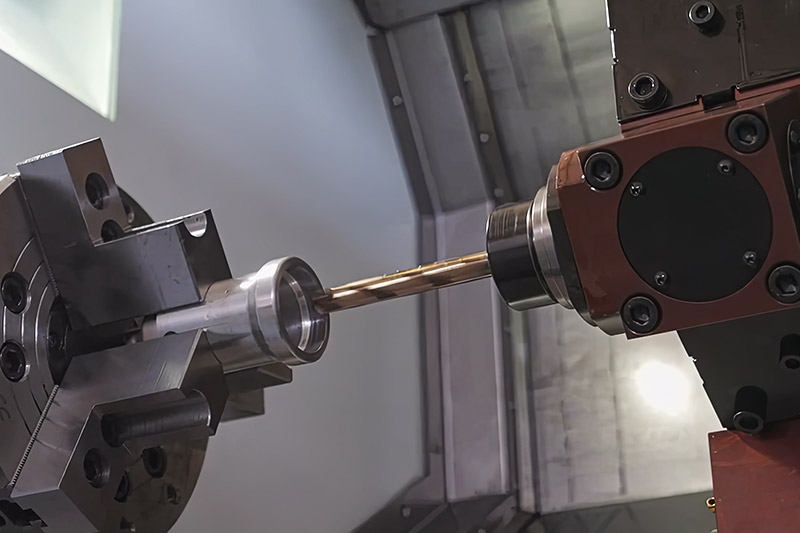

In the world of modern manufacturing, precision and efficiency are key. One of the most advanced techniques used to achieve these goals is Horizontal CNC Turning. But what exactly is Horizontal CNC Turning, and how does ...

READ MORE -

If you work in the manufacturing industry, especially in the field of precision parts machining, you have certainly encountered or at least heard of turret inclined bed CNC lathes. This equipment is very popular in the m...

READ MORE -

In the manufacturing industry, the turret inclined bed CNC lathe, as a high-precision and high-efficiency processing equipment, has become an important tool on the production lines of many enterprises. Through automated ...

READ MORE

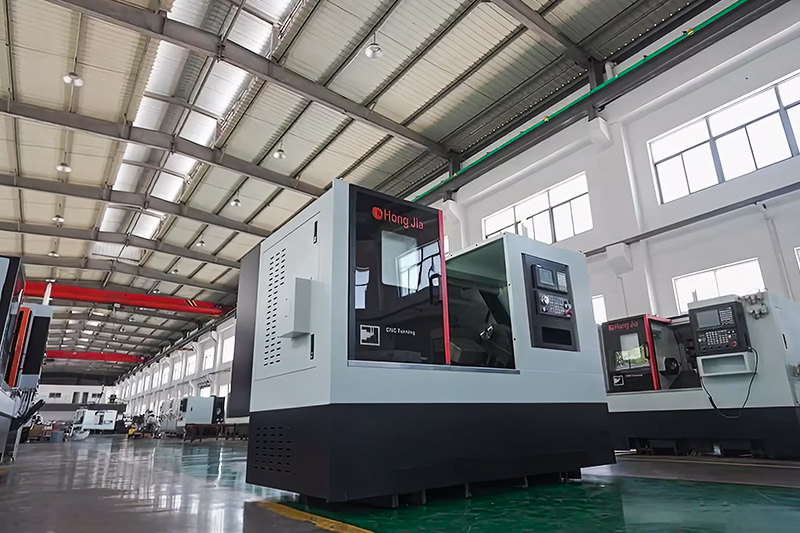

Ningbo Hongjia CNC Technology Co., Ltd. has been committed to providing customers with the most advanced CNC solutions since its establishment, aiming to help enterprises in all walks of life achieve a double leap in production efficiency and product quality. As a professional Double Column Machining Center supplier and customization factory, Hongjia CNC deeply understands that in the increasingly fierce market competition, only continuous innovation can keep an invincible position. Therefore, the company continues to increase R&D investment and optimize product design to ensure that every Double Column Machining Center shipped can reach the international leading level.

Double Column Machining Center: The perfect combination of stability and precision

Double Column Machining Center has demonstrated its unparalleled advantages in the field of large and heavy workpiece processing with its excellent rigidity and stability. Ningbo Hongjia CNC's Double Column Machining Center is the perfect interpretation of this concept. This series of machine tools adopts a high-strength cast iron bed, combined with a double-column structure, which effectively improves the overall rigidity and seismic resistance of the machine tool, and can maintain extremely high processing accuracy even under long-term and high-intensity operations. This design not only ensures high-quality output of the workpiece, but also greatly extends the service life of the machine tool.

High configuration creates high precision

Ningbo Hongjia CNC never compromises on the selection of core components. Its Double Column Machining Center is equipped with top-level components such as "Gintech PMI", "HIWIN" or "THK" C3-level precision ball screws, which ensure the stability and accuracy of the machine tool during movement. At the same time, the application of P4-level precision bearings further improves the rotation accuracy and load-bearing capacity of the machine tool. In addition, the use of "Speedcn" direct-drive spindle, combined with BT30-21T rotary servo tool magazine, not only achieves fast tool change, but also greatly improves processing efficiency and flexibility, meeting the needs of complex workpiece processing.

Efficient processing, flexible configuration

In order to meet the processing needs of different customers, Ningbo Hongjia CNC's Double Column Machining Center provides a variety of optional configurations. For example, the addition of the high-speed BBT30 spindle makes the machine tool perform well in high-speed cutting, which is particularly suitable for occasions with extremely high material removal rates in industries such as aerospace and automobile manufacturing. The larger tool library makes the machine tool more handy when handling multi-task and multi-variety processing, without the need to frequently change tools, further improving production efficiency.

Safety protection and intelligent maintenance

Safety is the premise of production, and Ningbo Hongjia CNC has a deep understanding of this. Its Double Column Machining Center has a full-axis covered protective cover, which effectively prevents cutting fluid and debris splashing, providing a safe working environment for operators. At the same time, the built-in automatic lubrication system ensures good lubrication of all parts of the machine tool, reduces wear and extends the life of the equipment. The rapid tool change function, combined with intelligent fault diagnosis and maintenance prompts, makes equipment maintenance more convenient and efficient, ensuring the continuous and stable operation of the production line.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى