Don't hesitate to contact when you need us!

What is Horizontal CNC Turning and How Does It Benefit Modern Manufacturing?

2026.01.22

2026.01.22

Industry News

Industry News

In the world of modern manufacturing, precision and efficiency are key. One of the most advanced techniques used to achieve these goals is Horizontal CNC Turning. But what exactly is Horizontal CNC Turning, and how does it benefit industries that rely on precision machining?

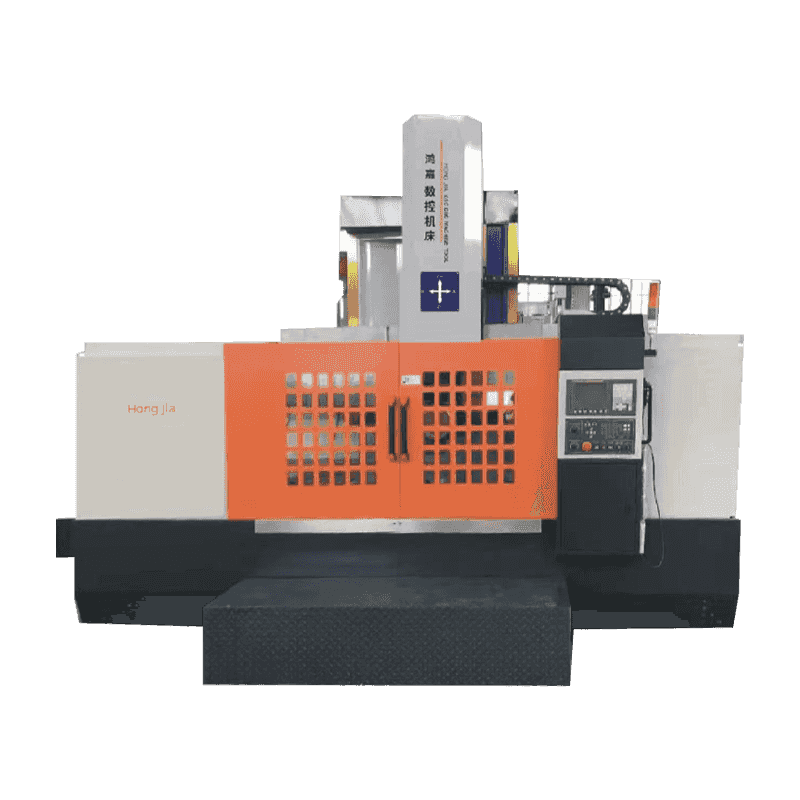

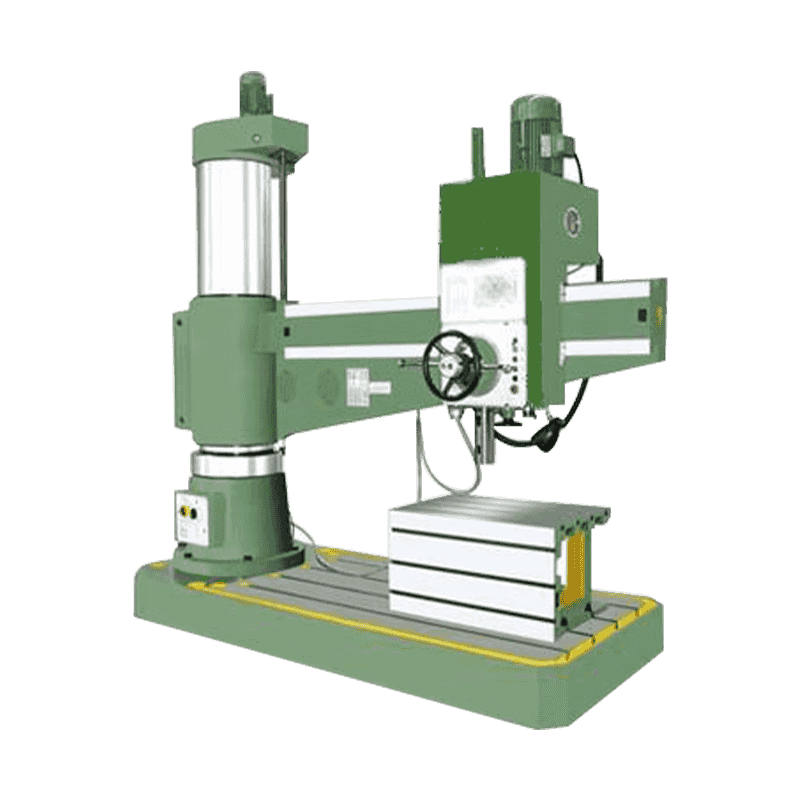

Horizontal CNC Turning is a machining process that uses a computer-controlled (CNC) turning machine to shape and cut materials, typically metals, into specific designs. In this process, the workpiece is mounted on a horizontal axis, allowing for greater stability and better chip removal during the cutting process. CNC stands for Computer Numerical Control, which means that the movement of the machine tools is controlled by a computer program that ensures precision and repeatability.

Unlike vertical CNC turning machines, which have a vertically oriented spindle, horizontal CNC turning machines have a spindle positioned horizontally. This configuration provides advantages in terms of heavy-duty cutting, part stability, and improved chip flow. Horizontal CNC turning is used to create cylindrical and other complex shapes with high precision, making it indispensable in industries such as aerospace, automotive, and medical manufacturing.

Content

Key Features of Horizontal CNC Turning

Several features make Horizontal CNC Turning a preferred choice for many industries:

- High Precision: Horizontal CNC Turning machines are capable of producing parts with incredibly tight tolerances, making them ideal for industries that require high-precision components, such as aerospace and automotive manufacturing.

- Increased Stability: The horizontal configuration of the machine ensures greater stability during machining, particularly for heavier and larger workpieces. This setup helps to reduce vibrations, ensuring smoother and more accurate cuts.

- Efficient Chip Removal: With a horizontal orientation, the chips produced during machining can fall away more easily, reducing the risk of them interfering with the cutting process and improving the overall efficiency of the machine.

- Versatility: Horizontal CNC turning machines can perform a wide range of operations, including drilling, facing, turning, and threading, making them highly versatile for different types of manufacturing needs.

Applications of Horizontal CNC Turning

Horizontal CNC Turning is used in a variety of applications across different industries. Some of the most common include:

- Aerospace Industry: In aerospace, precision is critical. Horizontal CNC turning is used to manufacture turbine blades, engine components, and other intricate parts that must meet strict quality standards.

- Automotive Industry: In automotive manufacturing, parts like crankshafts, brake discs, and gear shafts are commonly produced using Horizontal CNC Turning. The high precision offered by these machines ensures that components meet the necessary specifications for performance and safety.

- Medical Industry: Medical devices often require parts that are both precise and reliable. Horizontal CNC turning is used to produce components like surgical tools, implants, and prosthetics, which must adhere to strict health and safety regulations.

- Oil and Gas Industry: The oil and gas industry requires durable and precise parts for drilling rigs, pumps, and valves. Horizontal CNC turning machines are capable of producing these heavy-duty components with high accuracy and reliability.

Advantages of Horizontal CNC Turning

Horizontal CNC Turning offers several benefits, making it a top choice for industries that require precision machining:

- Increased Productivity: CNC turning is automated, which reduces the need for manual intervention. This automation leads to faster production cycles, lower labor costs, and increased throughput, ultimately boosting overall productivity.

- Cost-Effectiveness: The precision and efficiency of Horizontal CNC Turning reduce material waste and scrap. This leads to cost savings, especially for industries that deal with expensive raw materials like titanium or high-grade steel.

- Consistency and Repeatability: Since the process is computer-controlled, Horizontal CNC Turning ensures that each part produced is identical, providing consistency and repeatability that manual machining cannot achieve.

- Enhanced Safety: Automated systems reduce human error and the risk of workplace accidents. Additionally, operators can monitor and control machines from a safe distance, further enhancing the safety of the manufacturing process.

How Horizontal CNC Turning is Transforming Manufacturing?

Horizontal CNC Turning has revolutionized manufacturing in several key ways. By enabling manufacturers to produce high-precision parts with minimal human intervention, it has made mass production more efficient and reliable. This technology allows manufacturers to meet the growing demand for complex components in industries that require high performance, such as aerospace, automotive, and medical devices.

Furthermore, the versatility of Horizontal CNC Turning machines means they can be adapted to produce a wide range of parts, from small, intricate components to large, heavy-duty pieces. This flexibility allows manufacturers to diversify their offerings and cater to a broader range of industries, enhancing their competitive edge in the market.

Horizontal CNC Turning is a cornerstone of modern manufacturing, offering unmatched precision, efficiency, and versatility. Whether you're producing complex aerospace components or automotive parts, this machining technique ensures that your products meet the highest standards of quality. By embracing Horizontal CNC Turning, manufacturers can not only improve their production processes but also stay competitive in an ever-evolving market. As technology continues to advance, the role of CNC turning machines in manufacturing will only become more critical to achieving innovation and excellence.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى