Don't hesitate to contact when you need us!

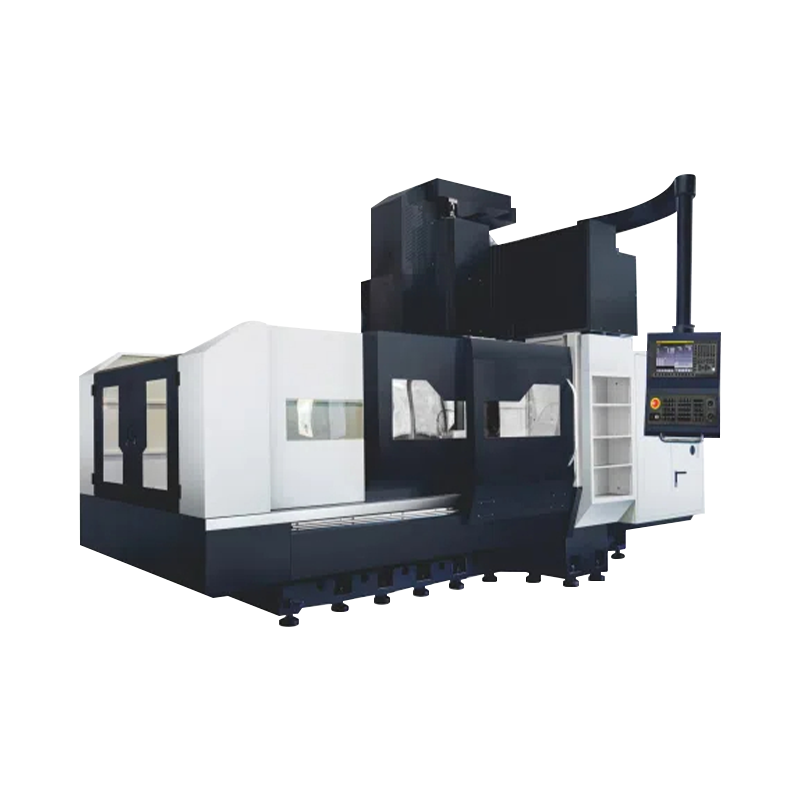

Vertical Milling Center: The Smart Solution for High-Precision Machining

2026.01.30

2026.01.30

Industry News

Industry News

A vertical milling center is one of the most widely used CNC machining systems in modern manufacturing. Known for its accuracy, productivity, and versatility, this machine plays a key role in industries such as automotive, aerospace, mold making, and general metal fabrication. In this guide, you will learn how a vertical milling center works, why it is important, and how to choose the right model for your production needs.

Content

- 1 What Is a Vertical Milling Center?

- 2 Why Is a Vertical Milling Center Important for Modern Manufacturing?

- 3 What Are the Main Applications of a Vertical Milling Center?

- 4 How to Choose the Right Vertical Milling Center?

- 5 How Can a Vertical Milling Center Improve Production Efficiency?

- 6 FAQ: Vertical Milling Center Common Questions

What Is a Vertical Milling Center?

Short Answer: A vertical milling center is a CNC machine tool that uses a vertically oriented spindle to perform cutting, drilling, tapping, and milling operations.

Unlike traditional manual milling machines, a vertical milling center is controlled by a computer numerical control system. This allows manufacturers to produce complex parts with consistent quality and tight tolerances. The vertical spindle design provides better visibility of the cutting area and makes setup easier, which is why vertical milling centers are preferred for precision machining tasks.

Why Is a Vertical Milling Center Important for Modern Manufacturing?

Short Answer: It improves productivity, machining accuracy, and automation efficiency.

In today's competitive manufacturing environment, speed and quality are critical. A vertical milling center allows manufacturers to reduce manual labor, minimize human error, and shorten production cycles. Automated tool changing and programmable operations enable continuous machining with minimal downtime. This leads to higher output and lower production costs.

- Improves machining precision and repeatability

- Reduces production cycle time

- Supports automated manufacturing processes

- Enhances overall production efficiency

What Are the Main Applications of a Vertical Milling Center?

Short Answer: It is widely used for metal parts, molds, prototypes, and precision components.

Vertical milling centers are suitable for a wide range of industries. They can process materials such as aluminum, steel, stainless steel, and composite materials. These machines are commonly used for machining engine parts, electronic housings, medical components, and custom mechanical parts. Their flexibility makes them ideal for both small batch production and mass manufacturing.

Below is a comparison of typical applications and machining requirements:

| Industry | Common Parts | Machining Focus |

| Automotive | Engine components | High precision |

| Aerospace | Structural parts | Tight tolerances |

| Mold Making | Injection molds | Surface quality |

How to Choose the Right Vertical Milling Center?

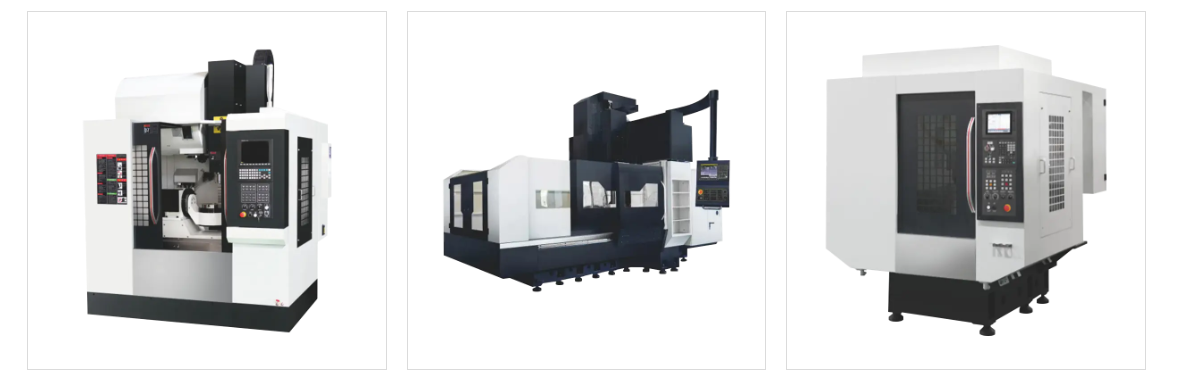

Short Answer: Choose based on workpiece size, spindle speed, rigidity, and automation requirements.

Selecting the right vertical milling center depends on your production needs. Important factors include table size, maximum load capacity, spindle power, tool magazine capacity, and control system compatibility. High-speed spindles are ideal for aluminum machining, while high-torque spindles are better for cutting hard metals. Machine rigidity and thermal stability also play a key role in maintaining machining accuracy.

- Consider workpiece dimensions and weight

- Evaluate spindle speed and torque

- Check tool changer capacity

- Assess automation and upgrade options

How Can a Vertical Milling Center Improve Production Efficiency?

Short Answer: It enables faster machining, reduced setup time, and consistent output quality.

With advanced CNC control systems, a vertical milling center can execute complex machining programs with minimal operator intervention. Features such as automatic tool changers, high-speed cutting, and real-time monitoring allow manufacturers to maximize machine utilization. This results in shorter lead times, improved part quality, and better return on investment.

FAQ: Vertical Milling Center Common Questions

Q1: Is a vertical milling center suitable for small workshops?

Answer: Yes, compact vertical milling centers are ideal for small and medium workshops due to their space-saving design and high efficiency.

Answer: Yes, compact vertical milling centers are ideal for small and medium workshops due to their space-saving design and high efficiency.

Q2: Can a vertical milling center machine different materials?

Answer: Yes, it can machine aluminum, steel, stainless steel, and composite materials depending on spindle configuration and tooling.

Answer: Yes, it can machine aluminum, steel, stainless steel, and composite materials depending on spindle configuration and tooling.

Q3: How often does a vertical milling center require maintenance?

Answer: Regular daily inspection and scheduled preventive maintenance help ensure stable performance and long service life.

Answer: Regular daily inspection and scheduled preventive maintenance help ensure stable performance and long service life.

Q4: What industries benefit most from vertical milling centers?

Answer: Industries such as automotive, aerospace, electronics, mold making, and general manufacturing benefit greatly from vertical milling centers.

Answer: Industries such as automotive, aerospace, electronics, mold making, and general manufacturing benefit greatly from vertical milling centers.

By investing in a vertical milling center, manufacturers can achieve higher precision, improved productivity, and greater operational efficiency. This advanced machining solution continues to be a core component of smart manufacturing and industrial automation.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى