Don't hesitate to contact when you need us!

How to Perform Daily Maintenance and Care of CNC Lathes?

2025.12.03

2025.12.03

Industry News

Industry News

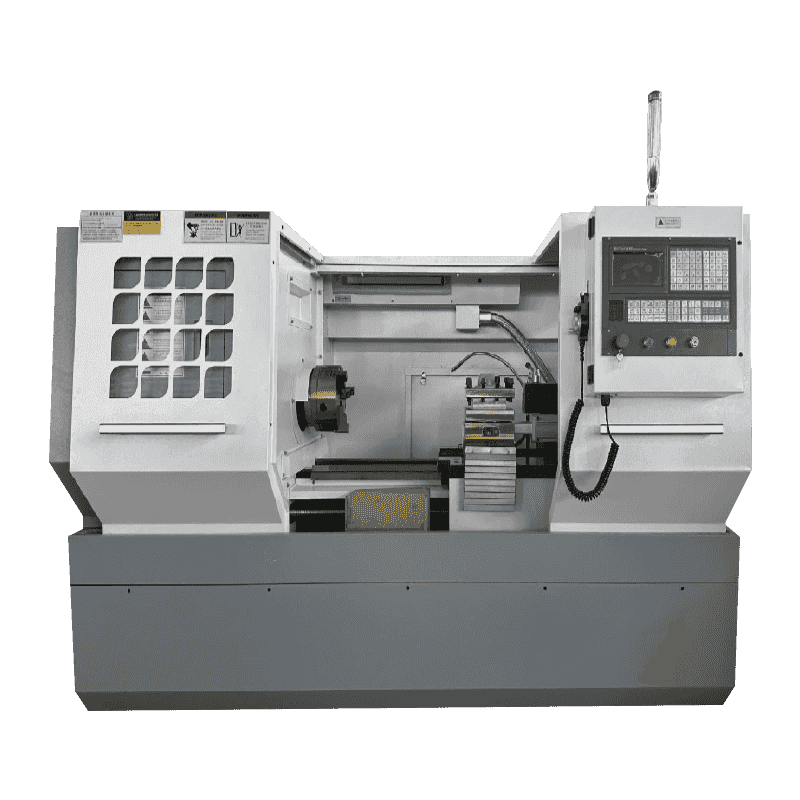

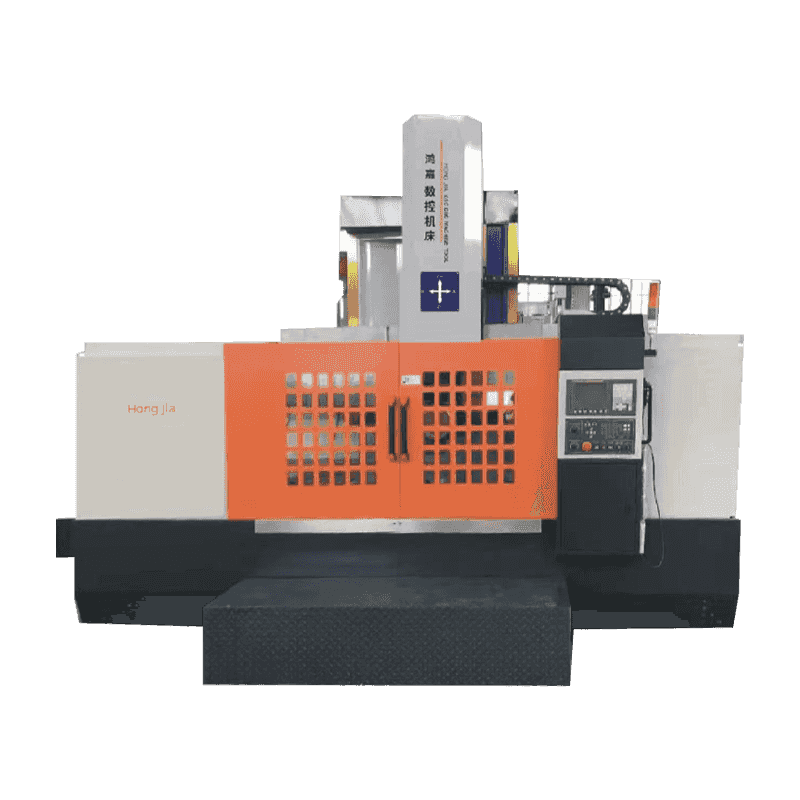

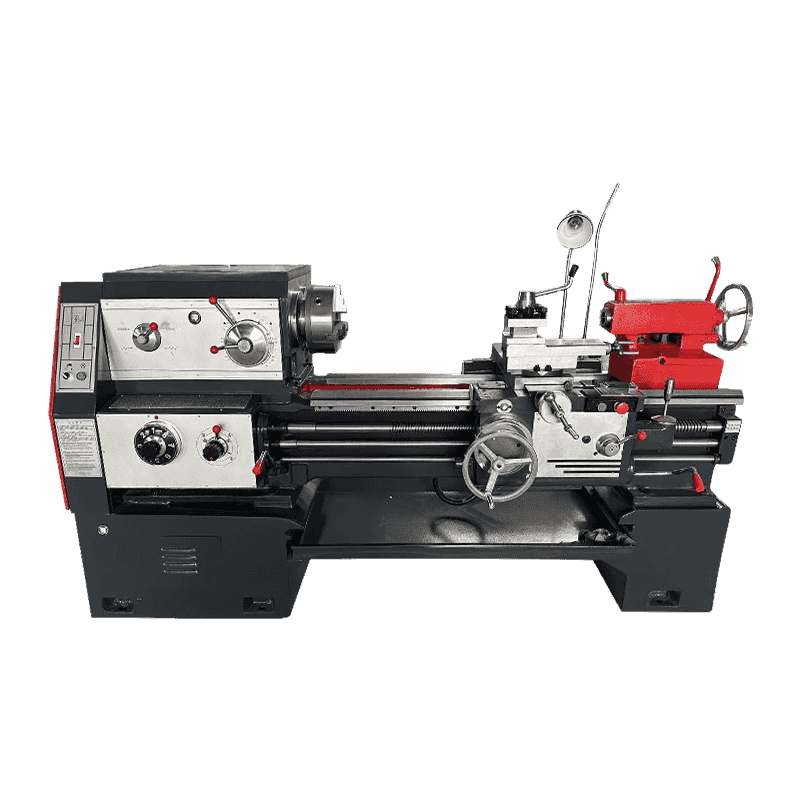

CNC lathes, as indispensable processing equipment in modern manufacturing, are widely used in various industries due to their high efficiency and high precision. Regular maintenance and care are crucial to ensure optimal performance and extend the service life of CNC lathes during production. Proper daily maintenance can not only reduce equipment failure rates but also improve production efficiency and machining accuracy.

1. Daily Inspection of CNC Lathes

(1) Checking Oil Level and Lubrication System

The lubrication system of a CNC lathe is key to maintaining the smooth operation of all moving parts. Operators should regularly check the lubricating oil level to ensure the lubrication system is working properly. Check if the lubricating oil is clean; if it becomes dirty or thickened, it should be replaced promptly. In addition, check for leaks or blockages in the lubrication lines to ensure that the lubricating oil reaches all moving parts adequately.

(2) Checking Coolant and Chip Removal System

The heat generated during long-term operation of a CNC lathe can affect machining accuracy and equipment performance. Operators should check the coolant level and quality to ensure the cooling system is operating normally. If the coolant deteriorates or becomes insufficient, it needs to be replaced or replenished promptly. Simultaneously, the chip removal system also needs regular inspection to ensure there are no obstructions, thus affecting chip removal efficiency and consequently machining efficiency.

(3) Electrical System Inspection

The electrical system of a CNC lathe is fundamental to its normal operation. When inspecting the electrical system, operators must ensure all cables and connectors are secure to prevent electrical faults or short circuits. Regularly inspect electrical components in the electrical cabinet, such as contactors, relays, and power boards, to ensure there are no loose parts, damage, or overheating. Additionally, check the CNC system's display screen, buttons, and operating interface for proper function to avoid affecting operation.

2. Maintenance of CNC Lathe Mechanical Components

Cleaning Machine Tool Surfaces and Guide Rails

During prolonged operation, oil, metal shavings, and dust easily accumulate on the guide rails and slides of a CNC lathe, affecting the machine tool's accuracy and smooth operation. After each workday, operators should use specialized cleaning tools to clean the machine tool surface, guide rails, and worktable to prevent dirt from entering precision components. Simultaneously, check the guide rails for damage or wear; if any abnormalities are found, repair them promptly.

Check the spindle and motor

The spindle and motor are the core components of a CNC lathe, and their working condition directly affects machining quality and efficiency. Operators should regularly check whether the spindle runs smoothly and whether there is any abnormal noise or vibration. The spindle bearings and the motor cooling system also need to be checked regularly to avoid overheating or poor lubrication. Ensure that the spindle lubricating oil is sufficient and free of contamination, and replace the spindle oil seal if necessary.

Check the tools and tool magazine

The tools of a CNC lathe are key components that directly affect machining quality. Regularly check the sharpness and wear of the tools, and replace severely worn tools in a timely manner. In addition, check the working condition of the tool magazine to ensure that the clamping device of the tool magazine is not loose and that the tool changing system is working properly. Operators should also clean the impurities in the tool magazine to ensure that the tools can be exchanged quickly and accurately.

3. Operation and maintenance of CNC lathe

(1) Ensure the CNC program is correct

The normal operation of a CNC lathe depends on an accurate machining program. Before machining, operators should carefully check the CNC program to ensure that the instructions in the program are correct. If an error is found in the program, it should be corrected immediately. (1) Regularly back up the CNC system program to avoid data loss or program corruption affecting production.

(2) Regularly check the accuracy

To ensure the CNC lathe can continuously perform high-precision machining, it is necessary to regularly check the machine tool's accuracy. This can be done by measuring the dimensions of machined workpieces and checking the accuracy of tool paths. If deviations in machine tool accuracy are found, they can be corrected by adjusting the machine tool's coordinate system or recalibrating the machine tool.

(3) Check and clean the chip removal device

CNC lathes generate a large amount of metal chips during machining. If these chips are not cleaned in time, they can easily affect the normal operation of the equipment. Regularly check and clean the chip removal system to ensure smooth chip removal. Also, ensure that the chip removal device is not worn or damaged to prevent metal chips from accumulating inside the machine tool and affecting its normal operation.

Daily maintenance and upkeep of CNC lathes are the foundation for ensuring stable and efficient operation of the equipment. Through regular inspection and timely maintenance, the equipment failure rate can be effectively reduced, its service life extended, and production ensured to proceed smoothly. Operators should develop good maintenance habits in their daily work, pay attention to the operating status of the equipment at all times, and perform regular inspections and maintenance according to the requirements of the equipment manual.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى