Don't hesitate to contact when you need us!

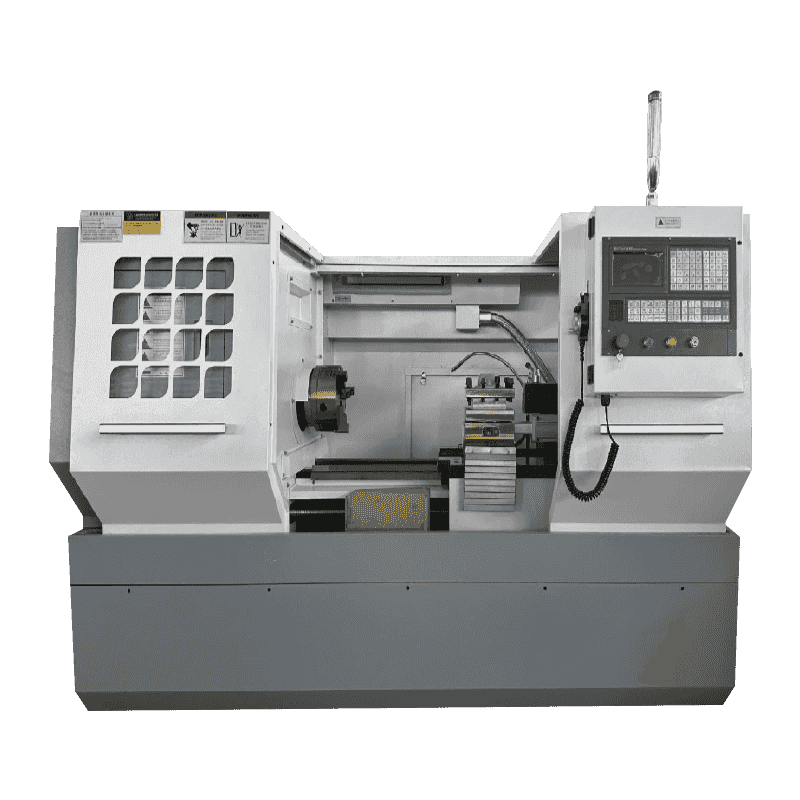

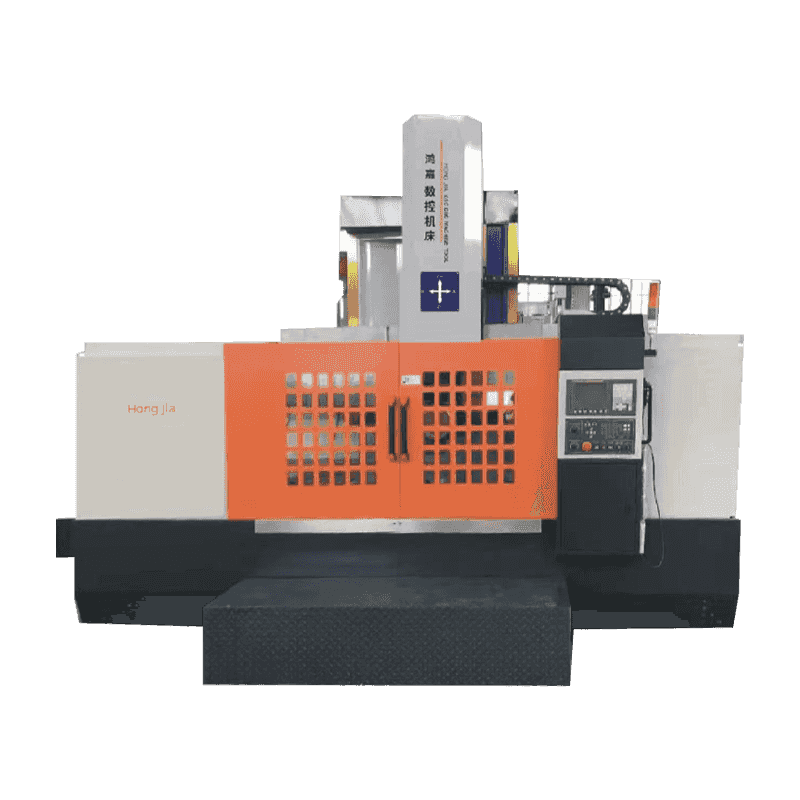

Maintenance and Care Guide for Vertical CNC Lathes

2025.11.25

2025.11.25

Industry News

Industry News

Vertical CNC lathes, as one of the important processing equipment in modern manufacturing, are widely used in aerospace, automobile manufacturing, precision instruments and other fields. Due to their high precision and high efficiency, vertical CNC lathes undertake heavy tasks in the production process. Therefore, daily maintenance and upkeep are crucial for extending the service life of the equipment, improving processing quality, and reducing the failure rate. This article will provide you with a maintenance and upkeep guide for vertical CNC lathes to help you better manage and maintain this equipment.

1. Daily Maintenance

(1) Cleaning

Cleaning is the most basic aspect of daily maintenance. The working environment of a lathe usually contains a lot of oil, iron filings, and dust. These impurities can affect the normal operation and accuracy of the machine tool. After each use, the operator should promptly clean the machine tool's worktable, tool magazine, guide rails, spindle, etc., especially the guide rails and transmission parts. Special cleaning agents and clean cloths should be used to clean these parts to prevent iron filings and impurities from accumulating on key components, leading to wear and malfunctions.

(2) Lubrication Inspection

The moving parts of a vertical CNC lathe, including guideways, lead screws, and spindles, all require lubrication. The quality and quantity of lubricating oil directly affect the machine tool's operating efficiency and accuracy. Operators should regularly check the lubricating oil level and replenish it promptly. Furthermore, the lubricating oil replacement cycle should be based on the manufacturer's recommendations; expired lubricating oil will affect lubrication and may even lead to excessive wear of parts.

(3) Fastening Inspection

During long-term operation, various components of a CNC lathe may loosen due to vibration. Operators should regularly check the screws, nuts, and other fasteners on the machine tool to ensure their tightness and avoid machining errors or more serious mechanical failures caused by loosening.

2. Regular Inspections

(1) Electrical System Inspection

The CNC system is the core of a vertical CNC lathe; electrical faults often lead to production stoppages. Regularly check the working status of the electrical system, including whether the wiring in the control cabinet is normal, whether the terminals are loose, and whether electrical components are damaged. In particular, the main motor, servo motor, and power supply system should be checked to ensure stable operation and avoid equipment failure due to electrical problems.

(2) Cooling System Inspection

Vertical CNC lathes typically require coolant for cooling during machining. Regularly check the working condition of the cooling system, including the coolant level, cleanliness, and operating status of the cooling pump. Coolant may deteriorate over time; therefore, replace the coolant regularly to ensure the normal operation of the cooling system.

(3) Spindle Inspection

The spindle is one of the most critical components of a CNC lathe, and its accuracy directly affects machining accuracy. Regularly check the spindle's operating status and accuracy, especially after high-load machining, checking for abnormal noises, excessive temperature, etc. Also, pay attention to the spindle's lubrication to avoid excessive wear due to insufficient lubrication.

3. Deep Maintenance

(1) Checking Mechanical Accuracy

As the usage time increases, the machining accuracy of a vertical CNC lathe may decrease. Regularly check the geometric and positioning accuracy of the machine tool, especially the wear of precision components such as guide rails, lead screws, and tool magazines. Adjust or replace them as necessary. Use specialized measuring tools, such as laser measuring instruments or levels, to ensure the equipment's accuracy meets requirements.

(2) Replacement of Wear Parts

During long-term use of CNC lathes, certain wear parts (such as seals, bearings, belts, etc.) will gradually wear down. Regularly check the condition of these wear parts and replace them promptly according to their wear. Neglecting the replacement of these wear parts may lead to more serious mechanical failures.

(3) Spindle and Servo Motor Maintenance

The servo motor and spindle are essential for the lathe's accuracy. Regularly check the operating status of the servo motor to ensure smooth operation and no overload. At the same time, check whether the spindle operates smoothly and whether there are any abnormal noises or vibrations. If any problems are found, repair them promptly.

During long-term shutdowns or holiday shutdowns, in addition to basic cleaning and lubrication, a comprehensive inspection of the equipment should be conducted to ensure normal operation when the equipment is put back into use. For easily corroded parts, apply rust-preventive oil to prevent rusting or corrosion caused by prolonged disuse.

Maintenance and upkeep of vertical CNC lathes are crucial for ensuring long-term stable operation, improving production efficiency, and enhancing machining accuracy. Daily cleaning, lubrication, regular inspections, and deep maintenance can extend the machine tool's lifespan and reduce the probability of malfunctions. In practice, operators and maintenance personnel should develop detailed maintenance plans based on the machine tool's usage and the manufacturer's maintenance manual, prioritizing prevention, regular inspections, and timely repairs.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى