Don't hesitate to contact when you need us!

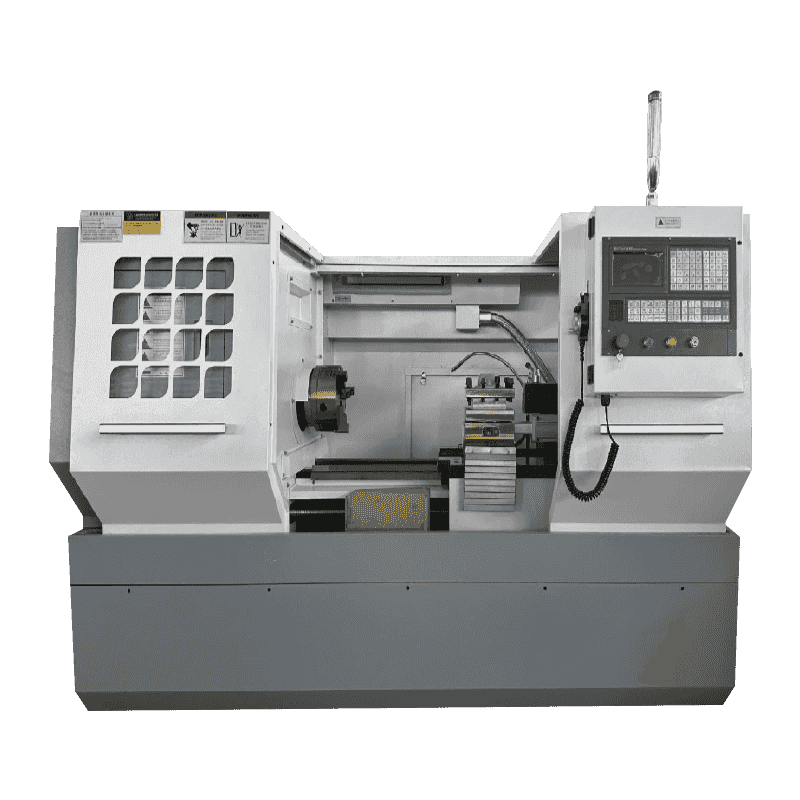

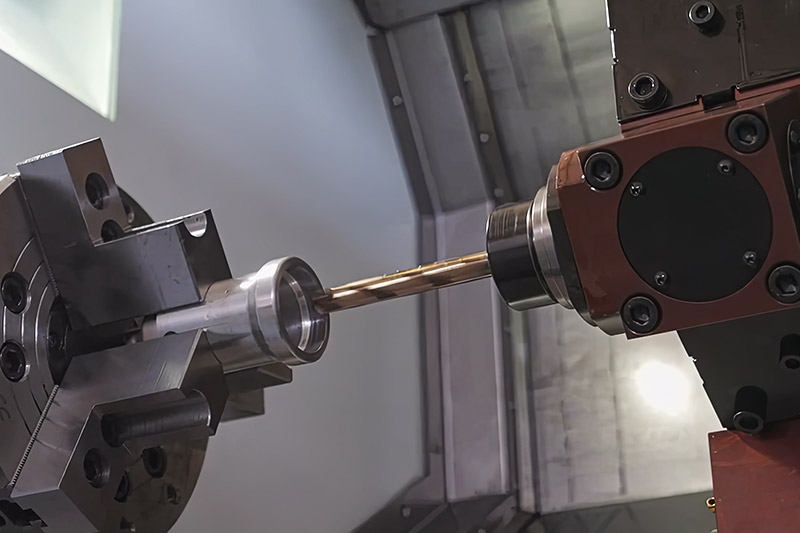

NC-115/1000 CNC lathe

The NC-115/1000 CNC lathe is equipped with the standard Japanese Fanuc0i-TF control system.

Designed, built and tested in full compliance with the ISO NC-115 turning centre rating (static accuracy, dimensional and cutting performance).

Maximum X-axis travel is 320mm, maximum Z-axis travel is 1000mm, and these figures are based on a standard 18.0’ (380mm) chuck with X-axis and Z-axis positioning accuracy of 0.008mm and repeatability of 0.005mm.

The wide working area of the bed is suitable for machining workpieces of various sizes: the maximum rotary diameter is 730mm, the maximum diameter of machined parts is 550mm, the maximum diameter of machined parts is 550mm, the maximum diameter of machined parts is 550mm.

NC115-1000 CNC lathe designed and manufactured by Hongjia adopts an integral 30-degree. Inclined bed structure, good rigidity and durability. All the structure and casting design adopt inverse finite element analysis. HONGJIA's unique design methodology ensures that all machine tools have more scientific and reasonable structural rigidity.

HONKA NC-115/1000 machine tool has a total weight of 6600kg and is made of high quality cast iron, which ensures the overall stability, rigidity and machining capability of the machine tool.

Spindle

The NC-115/1000 is equipped with a chuck-type spindle, and the nose model ANSIA2-11 is equipped with an 18.0’ (380mm) three-jaw power chuck with a set of soft jaws as standard.

Machine spindle motor power: 22 kw (continuous), 27.5 kw (15 minutes continuous).

The NC-115/1000 machine spindle is equipped with an Alpha motor drive with a speed of 1000 rpm and a rated torque of 285Nm (15 minutes) at a basic speed of 625 rpm.

The NC-115/1000 spindle is belt-driven.

The spindle has five bearings - one roller bearing and four angular contact bearings. One pair of angular contact bearings is mounted at the front and rear of the spindle to increase the overall rigidity of the spindle. 2 angular contact bearings are mounted at the front end of the spindle, 15 mm away from the roller bearings, to increase the runout accuracy of the spindle. The bearing bore at the front of the spindle is 170 mm.

The combination of roller bearings and angular contact bearings gives the system excellent thermal stability and increased radial and axial rigidity. The front end of the spindle is labyrinth sealed to prevent the external environment from affecting the inside of the spindle.

The spindle of the NC-115/1000 series is equipped with a non-contact magnetic encoder for rigid tapping, 1-degree indexing and spindle positioning.

The ultra-thin hydraulic clamping mechanism with coolant circuit system can be connected to a three-jaw power chuck or collet adapter to clamp workpieces. The machine has a small footprint due to the use of slimline rotary cylinders.

A hydraulic rotary cylinder pressure gauge is fixed on the left side of the front of the machine in order to observe the current force on the chuck or collet.

The hydraulic pressure of the rotary cylinder is adjustable from 74psi (5Kg/cm2) to 592psi (40Kg). Spindle clamping pressure can be easily adjusted through the left-hand service door. A safety interlock switch is mounted on the access door.

The spindle clamping pressure can be adjusted from 500kg to 4000kg. The maximum spindle travel of the spindle tie bar is 15 mm. The NC-115/1500 spindle tie bar has a throughput capacity of 120 mm.

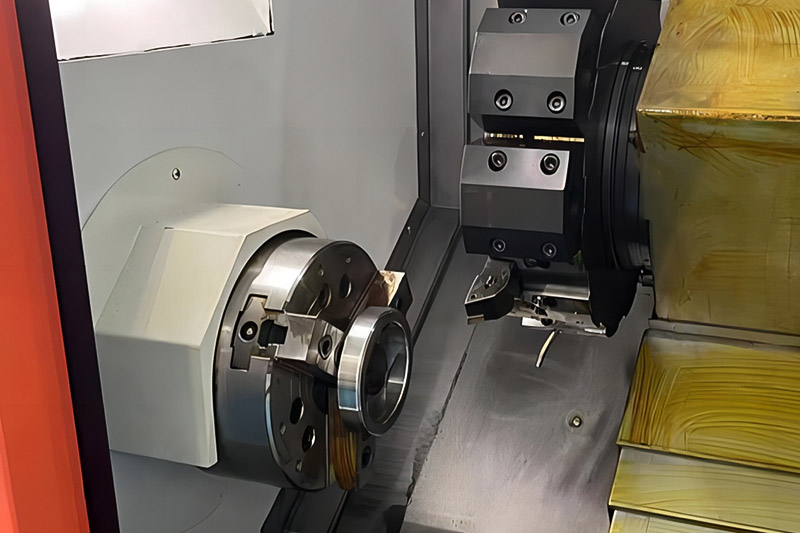

Servo turret

The NC-115/1000 is equipped with a standard 12-position bi-directional servo turret. It can be fitted with 25*25mm left and right-hand square shank tools and 50mm round shank tools, 12 stations.

The turret is driven by brushless servo motors and is accurately and reliably locked by a three-piece end gear disc. The turret's adjacent tool change time is only 0.18 seconds.

The turret's furthest tool position is indexed in 1.0 seconds. The turret repeatability is 2.5 arc seconds.

Guideways and Screws

The NC-115/1000 bed uses two Japanese #55/#55 precision linear ball guide rails on the X-axis and Z-axis, with two slides for each rail, which have very good rigidity and wear resistance.

Compared witha conventional sliding guide, a linear rolling guide has lower frictional resistance, no heat generation and less thermal expansion. In addition, the rolling guideway has higher positioning accuracy, faster feed speeds, shorter non-cutting times, reduced cycle times, less wear and tear, longer machine life and longer machining stability.

Rapid traverse speeds of up to 20m/min are available for the X- and Z-axes.

The NC-115/1000 series lathes are equipped with Yintai C-3 grade precision ballscrews in the X-axis and C-3 grade precision ballscrews in the Z-axis, which minimises thermal expansion and improves rigidity, stability and accuracy.

The X-axis ballscrew has a diameter of 40mm and a tooth spacing of 5mm. The Z-axis ballscrew has a diameter of 50mm and a tooth spacing of 10mm. The maximum thrust of the X-axis and Z-axis is 1080N.m.

Lubrication system

The NC-115/1000 is equipped with an automatic centralised lubrication system as standard, which allows easy oil lubrication of all moving parts of the machine and reduces downtime. The use of oil lubrication ensures reliable lubrication of all moving parts of the machine, reduces lubrication costs and is environmentally friendly.

Cooling system

The NC-115/1000 is ergonomically designed with thick sheet metal and cooling water tanks, which allows for full recycling of chips and cooling water, keeping the working environment clean.

The machine's sheet metal protects all major moving parts of the machine.

The machine is fitted with an internal sliding door with a large glass viewing window. The main door is safety interlocked. Water- or oil-based coolant can be used.

Coolant nozzles at the headstock end and over-turret cooling are standard. Coolant flow rate 12 litres/minute. Coolant tank capacity 125 litres, coolant pressure 18 bar.

Chip conveyor as standard

The removable chip conveyor is fitted with large-angle wheels and can be easily pulled out for cleaning.

Control system

All models of the NC-115/1000 are equipped with a chip conveyor preset interface. The RS-232-C interface is standard.

The NC-115/1000 machine's operating panel is easy to operate, with well-arranged buttons and easy-to-understand labelling. The keypad is made of polyester film and is highly reliable and resistant to damage.

Electrical Requirements

Machine dimensions: L 3980mm, W 2150mm, H 1920mm (with chip conveyor as standard). Approximate machine transfer weight: 8000kg.

The NC-115/1000 machine, when equipped with the Fanuc 0i-TF/puls control system, will be supplied with a full load 80 amp (FLA), (30kva) 220 volts, 3 phase, 50Hz. All other voltages will require an additional transformer.

Other

Rigid tapping is a standard feature on the NC-115/1000 and allows for precise synchronised movement of the spindle and Z-axis, ensuring accuracy and tapping speed. Tapping requires a floating tapping tool holder.

The X-axis and Z-axis are equipped with FANAUC/1.8Kw servomotors, which are directly coupled to the screws (rigid couplings) with no backlash loss in positioning. Flexible couplings at the joints eliminate assembly errors due to parallel or angular orientation.

The NC-115/1000 is equipped with a bright LED-illuminated work light, which facilitates the operator's view of the machine's working area. The NC-115//1000 is equipped with a three-colour status indicator to show the machine's operating status.

Pressure gauges mounted on the front of the machine provide easy access to the hydraulic system's main pressure, spindle clamping pressure and the optional hydraulic tailstock. Access to the interior of the machine can be gained through a removable side door to adjust the pressure of the hydraulic clamping unit and the optional hydraulic tailstock.

A complete set of documentation for the machine / CNC system.

Free 2.0 day commissioning training for programmers and operators by Honka technicians. The NC-115/1000 machine is supplied with a toolbox including spanners and tools.

Production Information

| Spindle | Spindle nose type | ANSI A2-11 |

| Spindle Through Hole Diameter | 130mm | |

| Three-jaw chuck clamping capacity | 18nch/380mm | |

| Spindle centre height | 1050mm | |

| Distance from spindle centre to front door | 410mm | |

| Tie bar action mode | Hydraulic | |

| FNAUC-0i-TF/plus control system | Spindle motor power | 22(continuous)/27.5(15min continuous)KW |

| Basic spindle speed | 1000rpm | |

| Maximum spindle speed | 1500rpm | |

| Spindle output torque | 285Nm/15min | |

| X-axis servo motor power | 2.4Kw | |

| Z-axis servo motor power | 2.4Kw | |

| Processing Range | Maximum bed turning diameter | 750m |

| Maximum workpiece length | 1050mm | |

| Maximum workpiece diameter | 500mm | |

| Maximum spindle bar passing capacity | 120mm | |

| X/Z axis movement | Maximum stroke | |

| X-axis | 350mm (SD ⼀ 160/8025 turret) | |

| Z-axis | 1060 mm | |

| X-axis/Z-axis rapid traverse speed | 20m/min | |

| Turret | Turret drive | Servo Motor |

| Number of tools | 12 | |

| Square shank holder size | 25*25mm | |

| Round shank holder size | 50mm | |

| Adjacent tool change time (T-T) | 0.18sec | |

| Tailstock-less | Tailstock travel | 700mm |

| Maximum Elevated Part Length | 960mm | |

| Minimum Overhead Part Length | 200mm | |

| Chip removal | Coolant capacity | 125 L |

| Coolant pressure | 1.2bar |

| Machine size | Length, Width, Height | 3580×2150×1950mm (without chip conveyor)/4800X2150X1950mm (with right side chip conveyor) | |

| Weight | 6600Kg | ||

| Option Configuration/Unavailable | |||

| Spindle holders | A2-15 | Through-hole diameter mm | |

| Feeder | Outrigger | Maximum workpiece diameter | 52 mm |

| Maximum workpiece length | 110 mm | ||

| Swing-arm | Maximum workpiece diameter | 52mm | |

| Maximum workpiece length | 150 mm | ||

| Workpiece conveyor | |||

| Automatic chip conveyor | Chain plate type | For long, curly chips (standard) | |

| Scraper type | Suitable for fine and random chips | ||

| Tool Measuring Device | Fully automated or manually operated | ||

| Workpiece measuring devices | |||

| Automatic centralised lubrication system | |||

| Oil mist collection device | 0.5 Hp | ||

| Bar machine (bar length) | 1250 mm | ||

| 3200 mm | |||

| High pressure over cutter tower cooling | Cooling Tank Capacity | 200L | |

| Cooling pressure | 20BAR | ||

| movable top | |||

| Automatic door | |||

| Standard accessories | |||

| Colour LCD display | 8.4″ | ||

| Three-jaw chucks and soft jaws | One Piece | ||

| Bar feeder interface | |||

| Automatic centralised lubrication system | |||

| Cooling tower | 1.2 bar | ||

| Waterproof work light | |||

| Work status indicator | three colours | ||

| Foot switch | |||

| Tool bag, manual | |||

Keep in Touch

-

In the world of modern manufacturing, precision and efficiency are key. One of the most advanced techniques used to achieve these goals is Horizontal CNC Turning. But what exactly is Horizontal CNC Turning, and how does ...

READ MORE -

If you work in the manufacturing industry, especially in the field of precision parts machining, you have certainly encountered or at least heard of turret inclined bed CNC lathes. This equipment is very popular in the m...

READ MORE -

In the manufacturing industry, the turret inclined bed CNC lathe, as a high-precision and high-efficiency processing equipment, has become an important tool on the production lines of many enterprises. Through automated ...

READ MORE

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى