Don't hesitate to contact when you need us!

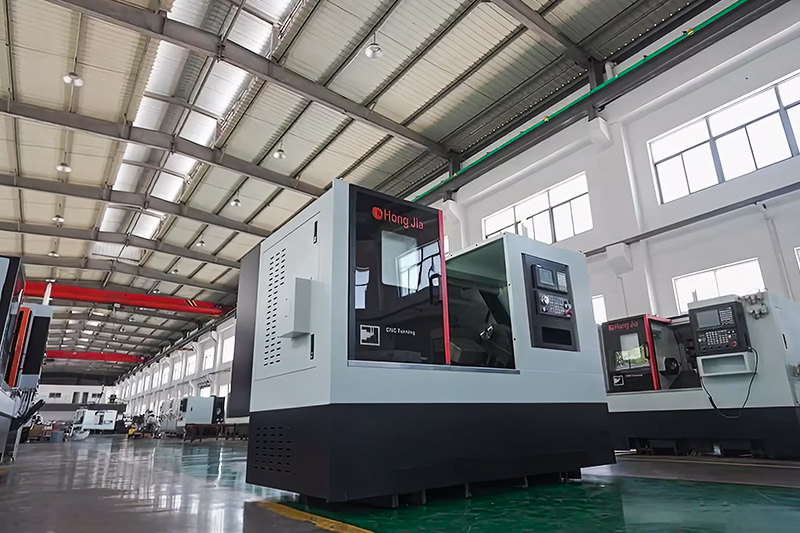

V600 CNC vertical lathe

V600 CNC vertical lathe is a high-rigidity, excellent cost-effective machine tool, the machine tool X-axis adopts an over-positioning dynamic column structure, configured with three guide rails, with a large bearing cross-section, so that the machine tool has a high degree of rigidity and shock-absorbing, can ensure high-precision, high-load cutting, can be inside and outside the cylindrical surfaces, inside and outside the conical surfaces, circular arcs, as well as complex shapes of the return surface of the high-speed turning of the ferrous metal, Non-ferrous metals and some non-metallic parts of rough and finish machining.

Overall: electromechanical integration design, compact structure, reasonable layout, beautiful modeling. Enclosed protection device, automatic rear chip removal, hydraulic power chuck automatic clamping. The whole machine adopts a finite element optimization design, reliable performance, good dynamic rigidity, and stable operation.

Base: The base is an integral box-type base, and the ribbed layout is optimally designed by finite elements, which makes the machine have good rigidity, and the material adopts high-density cast iron, which has high strength and good vibration-absorbing properties.

Column: A rectangular cross-section column is located on the base, the drag plate adopts three wire rails fixed to the column, one of which is supported at the bottom, so that the machine tool has better rigidity, can withstand heavy cutting, and maintains high accuracy for a long time.

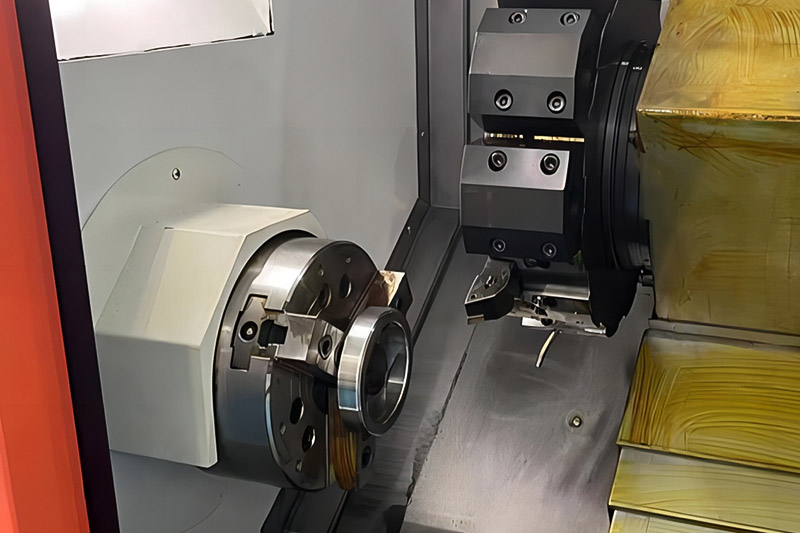

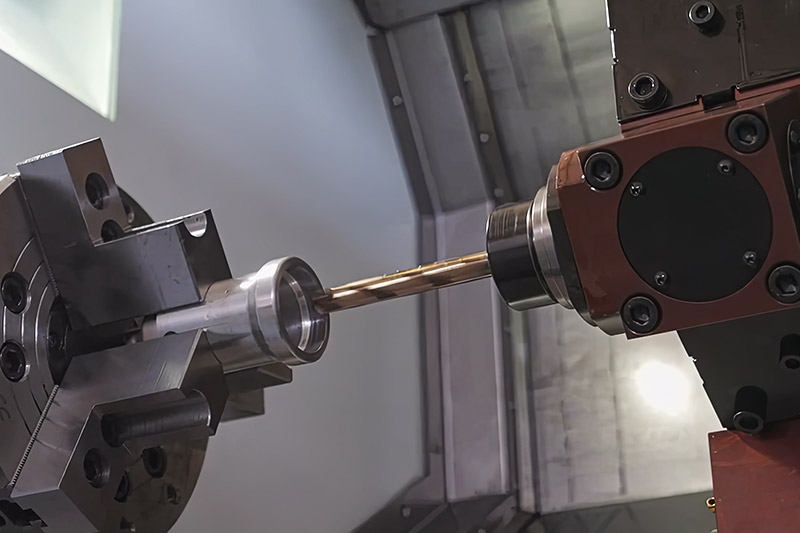

Spindle: The spindle is driven by a high-performance spindle motor, and the spindle bearing adopts imported high-precision double-row cylindrical roller bearings and bidirectional angular contact bearings, while the rear support adopts high-precision double-row cylindrical roller bearings, which can satisfy the requirements of axial and radial cutting force load bearing.

Tool holder: Imported high-performance horizontal hydraulic tool holder, featuring large cutting force, high reliability, and small machining interference. Feeding: X, Z direction tool traveling is driven by a servo motor, precision ball screw transmission, the screw adopts C3 level large diameter ball guide bar pre-pressure design, high rigidity, and good precision. Each axis guideway adopts a roller guideway, A linear roller guideway has the characteristics of high friction resistance, high precision, high load, etc., which is suitable for high-efficiency, precision heavy cutting machining.

System: Adopt FANUC 0i-TF PLUS(5) CNC system and AC longitudinal and transverse servo system, reliable performance.

Production Information

Machine configuration

V600 CNC vertical lathe is a high-rigidity, excellent cost-effective machine tool, the machine tool X-axis adopts an over-positioning dynamic column structure, configured with three guide rails, with a large bearing cross-section, so that the machine tool has a high degree of rigidity and shock-absorbing, can ensure high-precision, high-load cutting, can be inside and outside the cylindrical surfaces, inside and outside the conical surfaces, circular arcs, as well as complex shapes of the return surface of the high-speed turning of the ferrous metal, Non-ferrous metals and some non-metallic parts of rough and finish machining.

Overall: electromechanical integration design, compact structure, reasonable layout, beautiful modeling. Enclosed protection device, automatic rear chip removal, hydraulic power chuck automatic clamping. The whole machine adopts a finite element optimization design, reliable performance, good dynamic rigidity, and stable operation.

Base: The base is an integral box-type base, and the ribbed layout is optimally designed by finite elements, which makes the machine have good rigidity, and the material adopts high-density cast iron, which has high strength and good vibration-absorbing properties.

Column: A rectangular cross-section column is located on the base, the drag plate adopts three wire rails fixed to the column, one of which is supported at the bottom, so that the machine tool has better rigidity, can withstand heavy cutting, and maintains high accuracy for a long time.

Spindle: The spindle is driven by a high-performance spindle motor, and the spindle bearing adopts imported high-precision double-row cylindrical roller bearings and bidirectional angular contact bearings, while the rear support adopts high-precision double-row cylindrical roller bearings, which can satisfy the requirements of axial and radial cutting force load bearing.

Tool holder: Imported high-performance horizontal hydraulic tool holder, featuring large cutting force, high reliability, and small machining interference. Feeding: X, Z direction tool traveling is driven by a servo motor, precision ball screw transmission, the screw adopts C3 level large diameter ball guide bar pre-pressure design, high rigidity, and good precision. Each axis guideway adopts a roller guideway, A linear roller guideway has the characteristics of high friction resistance, high precision, high load, etc., which is suitable for high-efficiency, precision heavy cutting machining.

System: Adopt FANUC 0i-TF PLUS(5) CNC system and AC longitudinal and transverse servo system, reliable performance.

Technical Parameter

| Item | Unit | V-600 | |

| Processing scope | Maximum turning diameter (bed body/saddle) 最大车削直径 block type | Mm Mm | Φ600(Disk type) Φ450(Axis class) |

| Maximum workpiece height | Mm | 450 | |

| Hydraulic chuck diameter | Mm | Φ381(15") | |

| Principal axis | Spindle head type | A2-11 | |

| Specification of spindle cone hole | 1:20 | ||

| Main spindle through-hole diameter | Mm | Φ66 | |

| Spindle speed | rpm | 50-2000 | |

| The rated power of the main motor | KW | 15/18.5 | |

| Bed saddle | Axial stroke X/Z | Mm | 350/600 |

| Past movement speed X/Z | m/min | 16/20 | |

| Servo motor torque X/Z | Nm | 20/27 | |

| Bed guide rail width X/Z | MM | 35/45 (Roller type) | |

| Ball screw model X/Z | 4010/4010 | ||

| Knife holder | Knife number | Hold | 12 |

| Tool change time | Seconds/ station | 0.6 | |

| Tool size (turning/boring) | Mm | 32*32/Φ50 | |

| Other | Power capacity | KVA | 35 |

| Machine tool dimensions (length x width x height) (excluding chip conveyor) | Mm | 1750*2500*2700 | |

| Machine weight | Kg | 6200 | |

Keep in Touch

-

In the world of modern manufacturing, precision and efficiency are key. One of the most advanced techniques used to achieve these goals is Horizontal CNC Turning. But what exactly is Horizontal CNC Turning, and how does ...

READ MORE -

If you work in the manufacturing industry, especially in the field of precision parts machining, you have certainly encountered or at least heard of turret inclined bed CNC lathes. This equipment is very popular in the m...

READ MORE -

In the manufacturing industry, the turret inclined bed CNC lathe, as a high-precision and high-efficiency processing equipment, has become an important tool on the production lines of many enterprises. Through automated ...

READ MORE

V600 CNC Vertical Lathe: An efficient and precise metal cutting tool

1. Technology-led, creating an efficient processing platform

V600 CNC Vertical Lathe stands out among many similar products with its high rigidity and excellent cost-effectiveness. The X-axis of the machine tool adopts an ultra-positioning dynamic column structure, equipped with three guide rails and a wide bearing section, which ensures the high rigidity and excellent shock absorption performance of the machine tool. This design enables the V600 to easily cope with high-precision and high-load cutting tasks, whether it is rough processing and finishing of iron, non-ferrous metals or some non-metallic materials.

2. Mechatronics design, compact and beautiful structure

The overall design of V600 CNC Vertical Lathe embodies the advanced concept of mechatronics, with a compact structure, reasonable layout and beautiful shape. Its closed protective device effectively ensures operational safety, the automatic chip removal system reduces the burden of manual cleaning, and the hydraulic power chuck realizes automatic clamping of the workpiece, further improving processing efficiency. The machine tool adopts finite element optimization design as a whole, which ensures the reliability of performance, superior dynamic rigidity and stable operation, and provides a solid foundation for long-term high-quality processing.

3. Solid foundation, casting high-rigidity machine body

The base of the machine tool adopts an integral box structure. The rib layout is optimized by finite element method, combined with high-density cast iron material, giving the machine tool good rigidity and excellent seismic resistance. This design not only improves the overall stability of the machine tool, but also provides strong support for high-precision processing.

4. Solid column, bearing heavy cutting challenges

The rectangular cross-section column located on the base is equipped with three guide rails fixed on the column, one of which is a bottom support, which greatly enhances the rigidity of the machine tool, enabling it to withstand heavy cutting operations and maintain high precision for a long time.

5. High-performance spindle to meet complex processing requirements

The spindle of V600 CNC Vertical Lathe is driven by a high-performance spindle motor. The spindle bearings use imported high-precision double-row cylindrical roller bearings and bidirectional angular contact bearings. The rear end support also uses high-precision double-row cylindrical roller bearings. This configuration ensures that the machine tool can withstand large cutting forces in both axial and radial directions, meeting the high-precision requirements under complex processing conditions.

6. Efficient tool system to improve processing efficiency

The machine tool is equipped with an imported high-performance horizontal hydraulic tool holder, which has the characteristics of large cutting force, high reliability and low processing interference, and is an ideal choice for efficient processing. In terms of feeding, the tool movement in the X and Z directions is driven by a servo motor and driven by a precision ball screw. The screw adopts a C3-grade large-diameter ball guide rod pre-load design to ensure high rigidity and high precision. The guide rails of each axis are roller guide rails, which have the characteristics of low friction resistance, high precision and strong load-bearing capacity, and are very suitable for efficient and precise heavy cutting processing.

7. Advanced system ensures stable control

The V600 CNC Vertical Lathe adopts the FANUC 0i-TF PLUS(5) CNC system and AC longitudinal and lateral servo systems. The system performance is reliable, providing a solid guarantee for the efficient and stable operation of the machine tool. This configuration not only improves the processing accuracy, but also simplifies the operation process, making it easy to handle even complex processing tasks.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى