Don't hesitate to contact when you need us!

What is a CNC single-column vertical lathe? Why is it a powerful tool for machining heavy workpieces?

2025.10.31

2025.10.31

Industry News

Industry News

In modern industry, traditional horizontal lathes are often inadequate when faced with large wind turbine hubs, water turbine runners, or giant gear disks several meters in diameter. At this time, a towering "industrial giant" steps forward – the CNC single-column vertical lathe. So, what exactly is it? And what unique advantages make it an indispensable key piece of equipment in heavy equipment manufacturing?

Content

1. What is a CNC Single-Column Vertical Lathe?

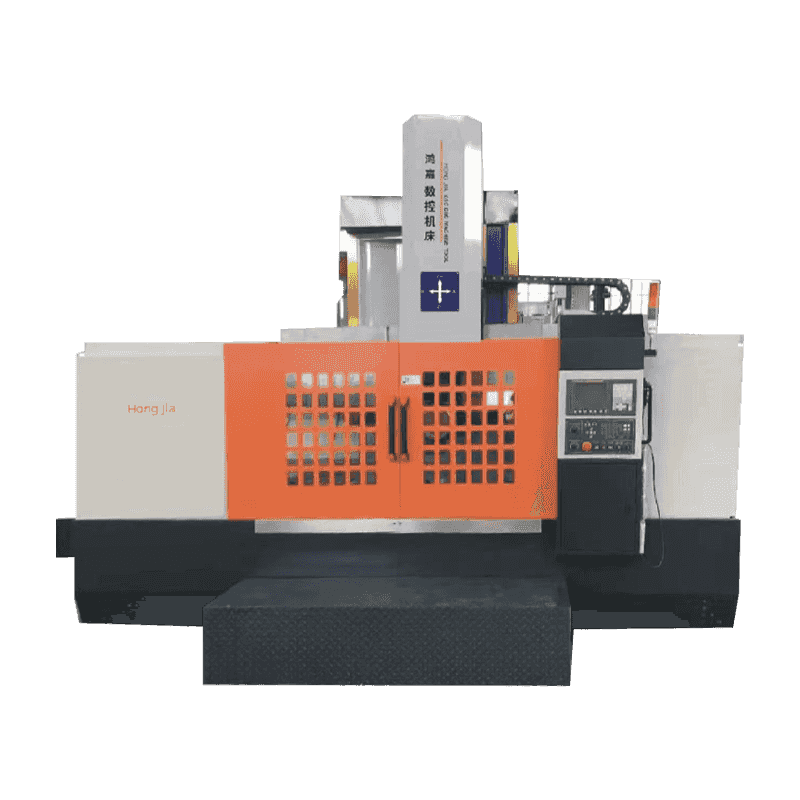

A CNC single-column vertical lathe is a CNC machine tool with a vertically arranged spindle and a worktable that rotates in a horizontal plane. Its "single-column" structure, like a giant gantry, is firmly integrated with the base, forming the main frame of the equipment.

Its core components include: Bed and Base: As the foundation of the entire machine, they are usually made of high-strength cast iron, possessing excellent shock resistance and stability, used to support huge workpieces.

Worktable (Circular Guide Rail):Located atop the base, this powerful rotating platform, driven by hydraulics or a servo motor, is used to clamp and rotate workpieces. This is its most obvious difference from a horizontal lathe.

Single Column:Standing upright on one side of the base, it is the main support structure of the machine tool and usually integrates a counterweight mechanism.

Cross Slide (Apron):Mounted on the column, it can move vertically (Z-axis) along the column guide rail.

Tool Post:Mounted on the cross slide, it can move horizontally (X-axis) along the crossbeam. This structure allows the tool post to move in both the X and Z directions, enabling complex surface turning.

CNC System (CNC):The "brain" of the machine tool, receiving machining program instructions and precisely controlling the movement of each axis, spindle speed, and tool post operation.

2. Irreplaceable Advantages

The design philosophy of the CNC single-column vertical lathe perfectly solves the pain points of machining large and heavy workpieces.

(1) Gravity as an ally, convenient and stable clamping

The workpiece is placed flat on the horizontal worktable and naturally positioned by its own weight. This not only simplifies clamping and alignment, but also provides excellent stability, effectively preventing bending deformation caused by its own weight and ensuring machining accuracy.

(2) Excels at machining large objects

This is its main battlefield. It typically processes discs, sleeves, and rings ranging in diameter from one meter to over ten meters, such as large gears, flanges, and engine rotors. Its structure is inherently designed to bear enormous weight and size.

(3) Smooth chip removal, protecting tools and workpieces

Due to the vertical spindle arrangement, the hot iron chips generated during cutting naturally fall to the chip conveyor at the bottom under gravity, preventing them from getting tangled on the workpiece or tool. This protects tool life, prevents iron chips from scratching the machined surface, and improves operational safety.

(4) High Rigidity and High Precision

Although the single-column structure is not as symmetrical as the double-column structure, with reasonable structural design and manufacturing, it still possesses extremely high rigidity and can withstand heavy cutting. Combined with an advanced CNC system, it can achieve micron-level machining accuracy.

(5) Relatively Small Footprint

Compared to double-column vertical lathes with the same machining range, single-column vertical lathes have a more compact structure and make more efficient use of factory space.

3. Main Application Areas

CNC single-column vertical lathes are "backbone" equipment in heavy machinery, energy, aerospace, and other fields.

Power Equipment: Hydropower turbine rotors, steam turbine components, wind turbine hubs and spindles.

Heavy Machinery: Large rolling mill rollers, large gears in mining machinery.

Aerospace: Engine casings, rocket components.

Shipbuilding: Large diesel engine cylinder heads, propeller components.

General Machinery: Various large flanges, mold frames, pump bodies and valve bodies.

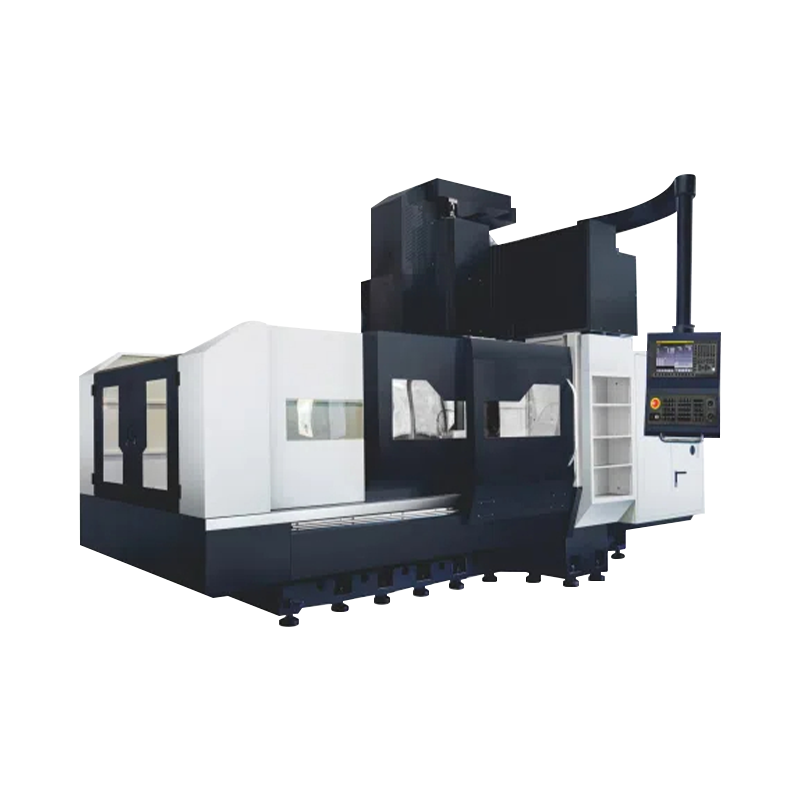

4. Brief Comparison with Two-Column Vertical Lathes

When workpiece size increases further, or when simultaneous machining from both sides is required, the two-column vertical lathe becomes a better choice. It features a "gantry" frame spanning the worktable, offering greater rigidity and better symmetry, but also a larger footprint and higher cost. The single-column vertical lathe can be seen as an optimized version in terms of economy and space efficiency, covering the machining needs of most heavy-duty workpieces.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى