Don't hesitate to contact when you need us!

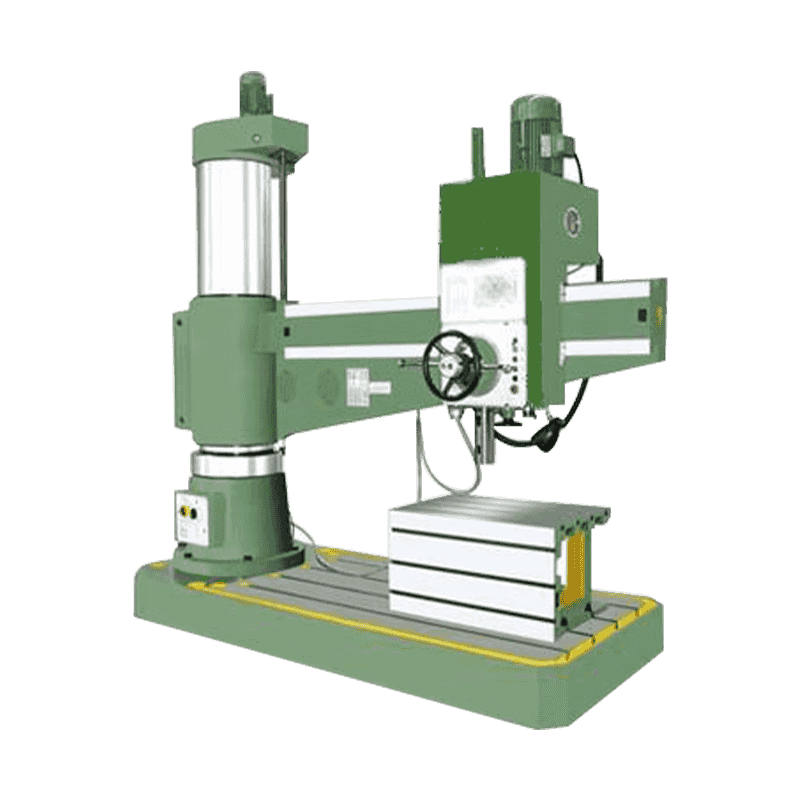

T-600A High Speed Drilling Center

Adopting Japanese precision ball guide rail, good load bearing, with low starting torque and high-efficiency power transmission.

Unique structural design, the main column adopts a multi-layer cross-bar structure, combined with a large span design, which provides excellent rigidity for the machine tool so that the machine tool has a high speed and high precision machining when smoothness.

The high-precision direct-connected spindle can be paired with the spindle high-pressure center out function to achieve drilling and tapping in one drill to the end of the rabbit lifting the knife, which greatly improves the processing efficiency and saves investment for the enterprise.

Developed the spindle express start-stop and quick tool change function, with the spindle and drag plate synchronous displacement significantly reducing the machining beat time, and improving the daily output.

Production Information

Technical Parameter

| Item | Unit | T600A | |

| Travel | X-axis(left and right machining range) | mm | 600 |

| Y-axis(front and back machining range) | mm | 400 | |

| Z-axis(upper and lower processing range) | mm | 320 | |

| Distance from spindle nose to work surface | mm | 200~520 | |

| Work Table | Table size | mm | 700×420 |

| T-shaped Cao dimensions | mm | 3×14×125 | |

| Maximum table load | kg | 250 | |

| Spindle | Spindle taper hole | BT20/BBT30 | |

| Spindle speed | rpm | 12000/20000 | |

| Spindle drive mode | Direct-connected | ||

| Feed | GO speed | m/min | 48/48/48 |

| G01 Maximum speed | mm/min | 10000 | |

| G01 Minimum speed | mm/min | 0.001 | |

| Tool Library | Tool library type | BT30 Clip arm type | |

| Tool storage capacity | hand | - | |

| Allowable weight | kg | 3 | |

| Maximum diameter | mm | None adjacent Φ140 | |

| Adjacent tool change time | s | 1.2 | |

| Machine Diameter | Footprint size | mm | 1800x2100x2300 |

| Machine weight | T | ≈3 | |

| Accuracy | Positioning accuracy XYZ(full stroke) | mm | 0.005 |

| Repeated positioning accuracy XYZ(full stroke) | mm | ±0.003 | |

Other

| Item | Unit | T600A |

| Air pressure requirement | kg/cm2 | 6-8 (Dual filtration system) |

| Electrical component | Schneider | |

| Voltage requirement | 380V±5%50Hz | |

| Temperature requirement | °C | 5-40 |

| Ground connection | Must be reliably grounded | |

| System configuration | New generation 22MA set |

Optional

| Item | |||

| 1. System | □Mitsubishi M80 | □ FANUC MF Plus | □New Generation |

| 2. Heieghtened probe column | □Raise to 620mm | ||

| 3. Axis rotate | □ 170mm | □ 210mm | |

| 4. Effuet core | □ 30bar | □ 50bar | □ 70bar |

| 5. Spindle coolant system | |||

Keep in Touch

-

In the world of modern manufacturing, precision and efficiency are key. One of the most advanced techniques used to achieve these goals is Horizontal CNC Turning. But what exactly is Horizontal CNC Turning, and how does ...

READ MORE -

If you work in the manufacturing industry, especially in the field of precision parts machining, you have certainly encountered or at least heard of turret inclined bed CNC lathes. This equipment is very popular in the m...

READ MORE -

In the manufacturing industry, the turret inclined bed CNC lathe, as a high-precision and high-efficiency processing equipment, has become an important tool on the production lines of many enterprises. Through automated ...

READ MORE

T-600A High Speed Drilling Center is the result of many years of technical accumulation and innovative wisdom of Ningbo Hongjia CNC Technology Co., Ltd. This product adopts Japanese precision ball guide rails. This design not only ensures good load-bearing capacity, but also reduces the starting torque and realizes efficient power transmission. The precision of the guide rails ensures the stability of the machine tool under high-speed operation, so that each processing can achieve micron-level precision requirements, meeting the stringent requirements of high-precision industries such as aerospace, automobile manufacturing, and mold processing for component precision.

The design team of T-600A High Speed Drilling Center has put a lot of effort into the structure of the machine tool. It adopts a unique multi-layer cross-beam structure as the main column, combined with a large-span design. This innovative structural design gives the machine tool excellent rigidity. This rigidity ensures that the machine tool can maintain excellent stability during high-speed processing, and can ensure the surface finish and dimensional accuracy of the workpiece even when performing complex curved surface processing or deep hole drilling. In addition, the optimization of the structure also greatly reduces vibration, extends the service life of the machine tool, and brings longer-term economic benefits to the enterprise.

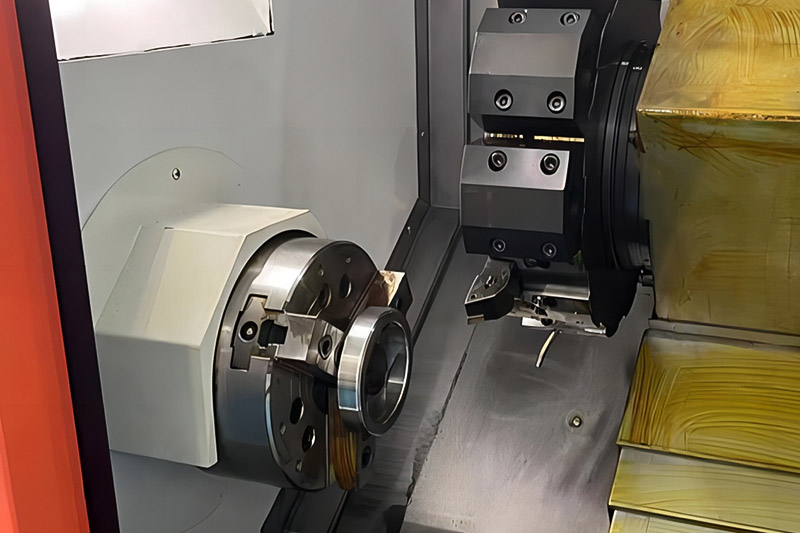

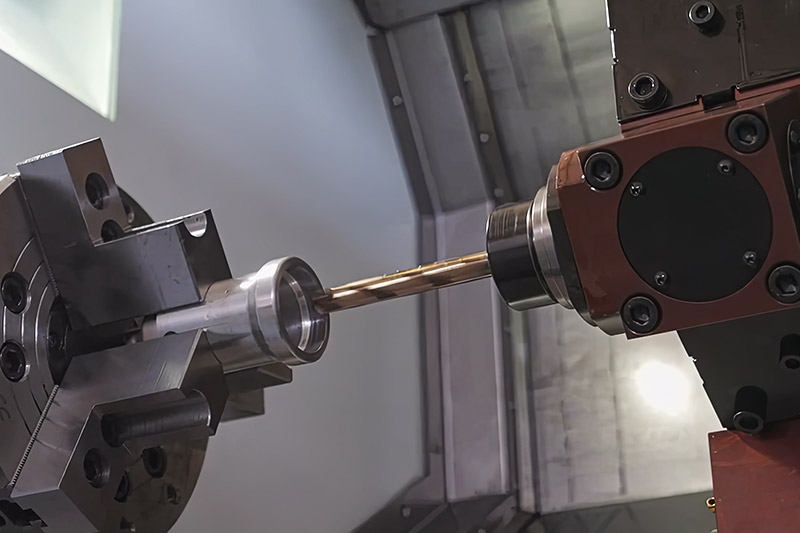

In terms of core components, the T-600A High Speed Drilling Center is equipped with a high-precision direct-connected spindle. This configuration, combined with the spindle's high-pressure center oil outlet function, realizes the integrated operation of drilling and tapping, that is, the entire process from drilling to tool lifting can be completed in one drilling process, without the need to change tools, greatly improving processing efficiency. For enterprises engaged in mass production, this means shorter production cycles and lower unit costs, thus gaining an advantage in the fierce market competition. Through this technological innovation, Ningbo Hongjia CNC Technology Co., Ltd has saved a lot of investment costs for enterprises and promoted industrial upgrading.

In order to further improve processing efficiency, the T-600A High Speed Drilling Center has also developed spindle quick start and stop and quick tool change functions. The addition of these two functions enables the spindle and the carriage to move synchronously, significantly reducing the tool change and positioning time during the processing process, and greatly improving the utilization rate of the machine tool. This function is particularly important for multi-variety, small-batch production modes, because it ensures that the machine tool can quickly adapt to the processing needs of different products in a short period of time, thereby achieving higher flexibility and production efficiency.

Ningbo Hongjia CNC Technology Co., Ltd knows that high-quality products cannot be separated from considerate services. Therefore, the company not only provides customized production of T-600A High Speed Drilling Center, but also has established a complete pre-sales consultation, sales guidance and after-sales tracking service system. Whether it is equipment selection, installation and commissioning, or operation training, repair and maintenance, Hongjia CNC can provide professional technical support to ensure that every customer can give full play to the performance advantages of T-600A High Speed Drilling Center and maximize production benefits.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى