Don't hesitate to contact when you need us!

Operation precautions for double column machining center

2025.10.24

2025.10.24

Industry News

Industry News

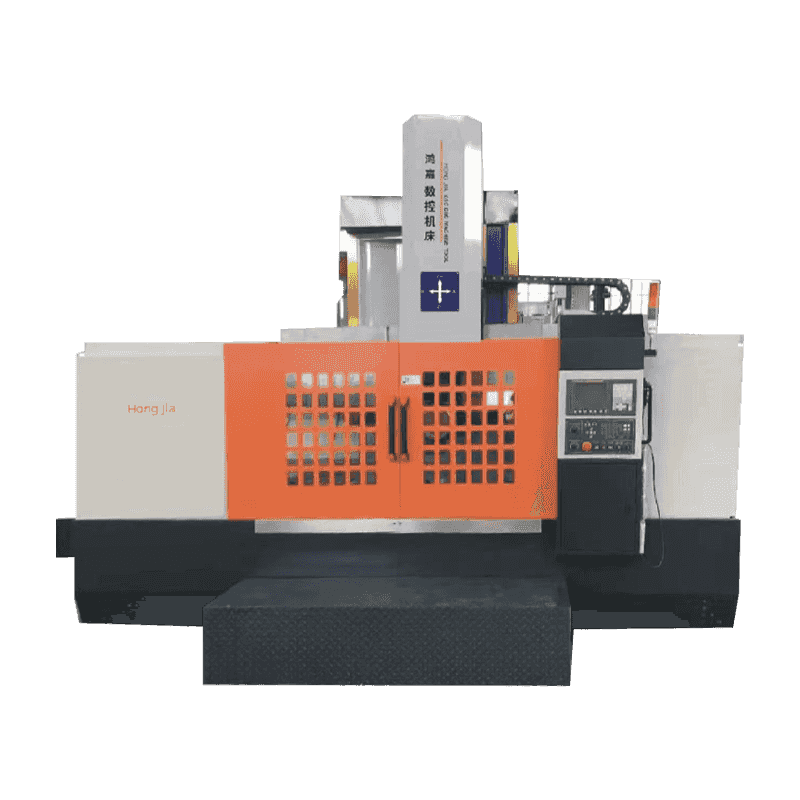

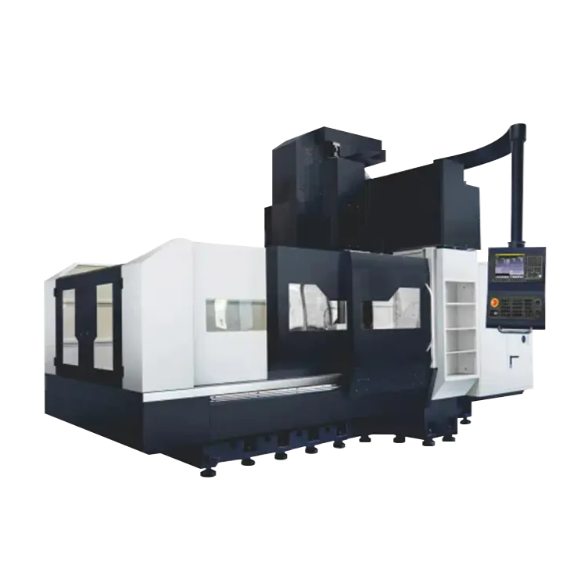

The double-column machining center (also known as the gantry machining center) is a high-precision, high-efficiency heavy-duty machine tool that is often used to process large and heavy workpieces and perform multi-faceted composite processing. Its operational complexity and safety risks are much higher than those of ordinary vertical machining centers. Understanding the key operating precautions of the double-column machining center can maintain the stable operation of the double-column machining center.

Content

1. Safety operating procedures (top priority)

Personal protection:

It is strictly prohibited to wear gloves: When operating machine tools, loading and unloading tools, or touching workpieces, it is strictly prohibited to wear gloves to prevent being caught in rotating parts.

Wear protective glasses: High-speed flying chips will be produced during processing, so protective glasses must be worn.

Standard dress: Wear tight-fitting work clothes, tie long hair into a work cap, and avoid any clothing or hair from getting entangled in moving parts.

Workpiece and fixture safety:

Reliable clamping: The workpiece must be firmly clamped on the workbench or fixture. For large workpieces, ensure stable support, sufficient clamping force and even distribution to prevent loosening or shifting during processing.

Check for interference: In program simulation or manual mode, run the program at low speed and check whether there is any risk of interference between the gantry, spindle head, tool and workpiece, fixture, and workbench. The double-column structure has a large space and the risk of interference is more concealed.

Equipment operation safety:

Access protection: The protective door must be closed during processing. It is strictly prohibited to extend any part of the body into the processing area when the machine tool is running.

Be familiar with emergency stops: Before starting the machine, confirm the location of all emergency stop buttons (usually near the operation panel, columns and moving parts) to ensure that they can be pressed immediately in an emergency.

Hoisting safety: When using cranes and other lifting equipment to load and unload large workpieces, lifting safety regulations must be followed, and people are strictly prohibited from standing under the workpieces.

2. Preparation and inspection before processing

Power on and warm up

After starting up every day, the machine tool must be allowed to warm up and run dry. Let the spindle, each axis screw, and guide rail run at low speed for 10-20 minutes without load, so that the temperatures of the bearings and lubricating oil will rise evenly and eliminate the impact of thermal deformation on accuracy. This is critical for large two-column machines.

Precise setting of workpiece coordinate system

Use edge finder, Z-axis setter and other tools to accurately measure and input the workpiece coordinate system. Since the workbench and workpiece can be very large, it is necessary to ensure that the coordinate system origin is exactly the same as the program setting.

Suggestion: Carry out "trial cutting" at important positions of the workpiece to verify the coordinate system.

Tool and tool magazine management

Accurate measurement: Use a tool setter to accurately measure the length and radius compensation value of each tool, and correctly input it into the tool offset table.

Checklist: Strictly follow the tool list of the machining program, load the tools into the tool magazine in sequence, and check the tool numbers to prevent calling errors.

Check the status of the tool: Before installing the tool, check whether the tool is worn or chipped, and whether the clamping is firm.

3. Monitoring and optimization during processing

First piece trial cutting and monitoring

Single-segment operation: When processing the first piece, use the "single-segment" mode to execute the program segment by segment and observe whether the movement and cutting of each tool are normal.

Adjust cutting parameters: Based on chip shape, sound and machine tool load, fine-tune spindle speed and feed rate within a safe range to find optimal parameters. Although the two-column machine tool has good rigidity, it must also avoid severe wear or chipping of the tool due to improper parameters.

Safety height setting: Ensure that the safety height for rapid movement in the program is set reasonably enough to span the highest points of all fixtures and workpieces.

Chip removal and cooling

Keep the cutting fluid sufficient and the nozzle direction correct to ensure effective cooling and chip removal.

Clean the chips accumulated on the workpiece and workbench promptly to prevent secondary cutting of chips from damaging the surface of the workpiece or interfering with the movement of the machine tool.

4. Post-processing and daily maintenance

Operation after completion

After the program is executed, move the spindle to a safe position and then stop the spindle.

Before removing the workpiece, clean the workbench and workpiece reference surface.

Measure the key dimensions and confirm that they are qualified before removing the workpiece.

Routine and scheduled maintenance

Clean chips and coolant from inside and outside the machine tool.

Check whether the air source and hydraulic system pressure are normal.

Check whether the guide rail and screw are well lubricated.

According to the manufacturer's requirements, regularly replace the spindle coolant, guide screw lubricating oil, hydraulic oil, etc.

Check and adjust the clearance and accuracy of transmission components (such as screws and guide rails).

Carry out machine tool horizontal accuracy detection and adjustment.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى