Don't hesitate to contact when you need us!

What is the function of horizontal CNC turning and milling?

2025.09.04

2025.09.04

Industry News

Industry News

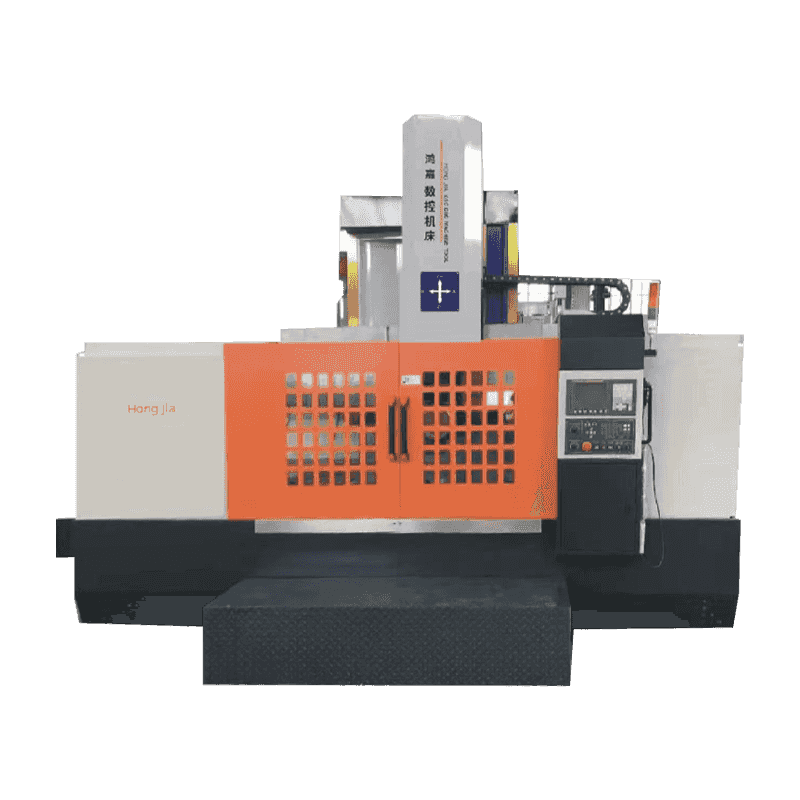

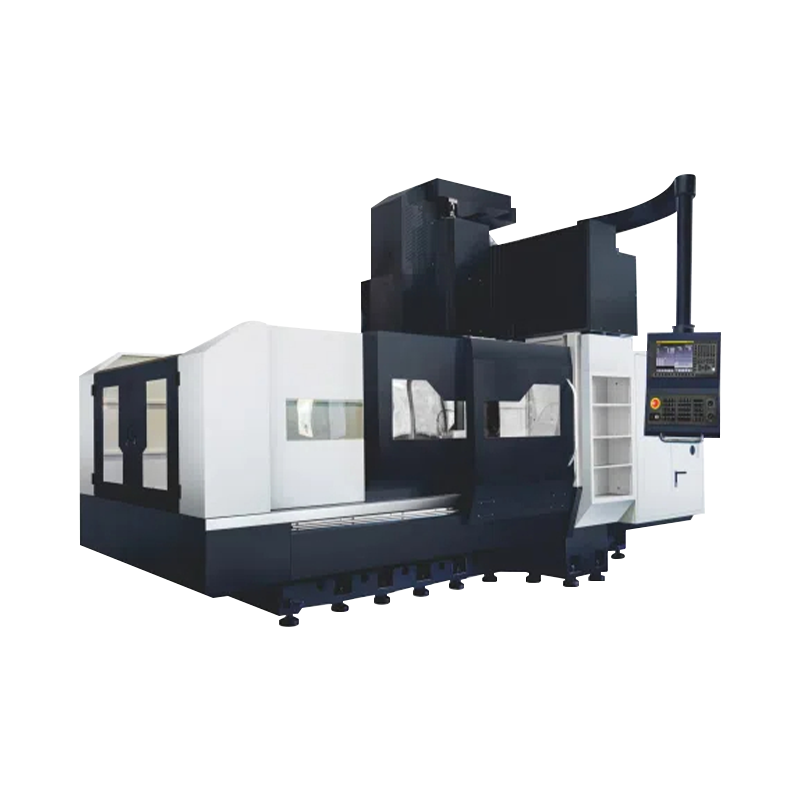

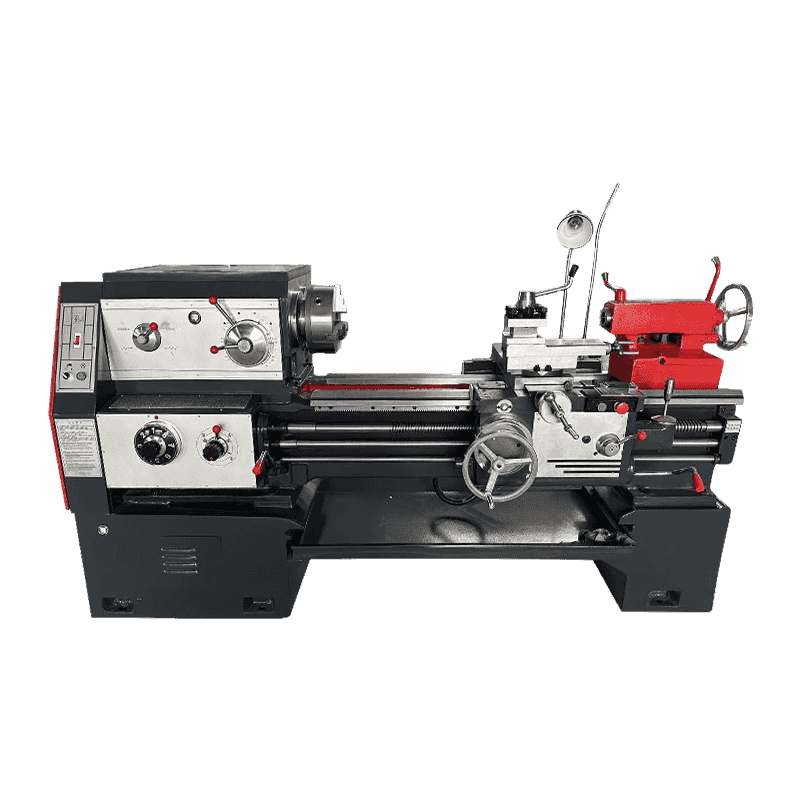

A horizontal CNC turning-milling center is a high-precision CNC machine tool that integrates turning, milling, and drilling. Its core function is to efficiently and comprehensively process complex parts, making it particularly suitable for high-volume, high-precision industrial component manufacturing.

1. Functions of Horizontal CNC Turning and Milling

Complex Processing and Reduced Process Steps

Turning and Milling Integration: Turning and milling operations are performed on a single machine, eliminating the need for multiple equipment changeovers and shortening production cycles.

Typical Applications: Parts requiring multi-faceted machining, such as aerospace engine rotors, hydraulic valve bodies, and automotive turbine housings.

High Precision and Stability

Advantages of the Horizontal Structure: The workpiece is placed horizontally, ensuring evenly distributed gravity and reducing vibration. Machining accuracy can reach IT5-IT6 (roughness Ra 0.8μm or less).

CNC System Control: G-code programming achieves micron-level precision with a repeatability error of ≤0.005mm.

High-Volume, Efficient Production

Automation Integration: Can be paired with a robot or material hopper to achieve 24/7 unmanned production, increasing efficiency by over 50% compared to traditional machine tools.

Multi-Spindle Design: Some models are equipped with dual spindles or a sub-spindle, enabling simultaneous machining of the front and back sides of workpieces.

Complex Part Processing Capabilities

Multi-Axis Linkage: Standard with 4 axes (X/Y/Z/B), and optional with 5 axes (including a C-axis), enabling machining of complex geometries such as impellers and spiral bevel gears.

Suitability for Large Workpieces: The horizontal layout avoids the cantilever effect of vertical machine tools and is suitable for long shafts (such as railway axles) or heavy parts.

2. Precautions for Using Horizontal CNC Turning and Milling Machines

Equipment Inspection

Machine Condition: Before starting the machine, check the lubrication system (guideway oil, spindle oil), air pressure (0.4-0.6 MPa), and coolant level to ensure they are normal.

Tools and Fixtures: Ensure that the tool is securely installed and free of damage; the clamping force is moderate to prevent workpiece deformation or loosening.

Program Verification: Before the first machining operation, perform a dry run to verify that the G code is correct and to avoid tool collision or overtravel.

Workpiece Clamping

Long-Shaped Workpieces: Use a tailstock or steady rest for support to prevent bending and deformation during machining.

Heavy Parts: Ensure that the worktable is evenly loaded to avoid uneven loading that could cause guideway wear.

Precision Parts: Use a dial indicator to calibrate the workpiece reference surface to ensure concentricity ≤ 0.01 mm.

Precautions During Machining

Cutting Parameter Optimization

Select Speed/Feed Rationally:

Carbide tools: Use high speed (e.g., 3000-8000 rpm) and moderate feed.

For heavy cutting: Reduce speed and increase cutting depth to avoid tool chipping.

For difficult-to-machine materials (e.g., titanium alloys and stainless steel):

Use high-pressure coolant (above 20 MPa) to reduce cutting temperatures.

Avoid prolonged continuous cutting to prevent thermal deformation.

Chip Removal and Cooling

Chip Management: Regularly remove chips to prevent accumulation that could affect machining accuracy or damage guide rails.

Coolant Maintenance:

Use rust-resistant cutting fluid with a concentration of 5%-10%.

Filter or replace the coolant monthly to prevent bacterial growth and clogging.

Multi-Axis Safety

For 5-axis machining:

Check the travel limits of the rotary axes (B/C axes) to avoid interference.

Pre-simulate the tool path using simulation software (e.g., VERICUT). Tool changing process: Make sure the tool magazine is aligned with the spindle to prevent collision during tool changing.

Common troubleshooting

|

Symptom |

Possible Cause |

Solution |

|

Spindle overheating |

Insufficient lubrication or bearing damage |

Stop the machine, check the oil circuit, and replace the bearings |

|

Processing dimension out of tolerance |

Tool wear or excessive screw backlash |

Replace the tool and adjust the pitch compensation |

|

Tool change failure |

Inaccurate tool magazine positioning or insufficient air pressure |

Recalibrate the tool magazine and check the air circuit |

|

Coolant leak |

Cracked pipe or deteriorated seal |

Replace the pipe or seal |

3. Operating Specifications

- Operator Protection

Gloves: Gloves are prohibited. Long hair should be tied up to prevent entanglement in rotating parts.

Emergency Stop: Familiarize yourself with the location of the emergency stop button and press it immediately in the event of an emergency.

- Processing Environment

Floor Cleanliness: Avoid oil stains and metal filings that could cause slips.

Fire Prevention: A fire extinguisher should be provided when processing flammable materials (such as magnesium alloys).

- Program Management

Data Backup: Processing programs and parameters should be saved regularly to prevent loss due to system failures.

Access Control: Non-professionals are prohibited from modifying CNC system parameters.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى