Don't hesitate to contact when you need us!

Quick Guide to Common Radial Drilling Machine Troubleshooting: From Unusual Noise to Loss of Accuracy, All in One Article!

2025.08.25

2025.08.25

Industry News

Industry News

Content

1. Troubleshooting Abnormal Noise in Radial Drilling Machines

Abnormal Spindle Box Noise (Buzzing/Metallic Friction)

Possible Causes:

Spindle bearings lacking lubrication or worn (common in equipment that has not been maintained for a long time).

Gearbox lubricant deteriorating or gears not meshing properly.

Belt loose or worn (V-belt drive models).

Solution:

Check the lubrication system: Ensure adequate oil levels in the spindle bearings and gearbox.

Replace the bearings: If the abnormal noise is accompanied by heat, disassemble and replace the spindle bearings.

Adjust the belt tension: Press the center of the belt with your finger until 5-8mm of depression is ideal.

2. Jamming/Stiffness in the Arm Lifting/Lifting

Difficulty in Lifting the Arm (Handle Unmovable)

Possible Causes:

Worn lifting screw or nut, resulting in poor engagement.

Insufficient guide rail lubrication, increasing friction.

Failed balance spring (common in older radial drills).

Solution:

Clean and lubricate the guide rails: Clean the guide rails with kerosene and then apply lithium-based grease.

Check the lead screw nut: If the play is excessive (>0.5mm), replace the nut (copper nuts are more wear-resistant).

Adjust the balance spring: Adjust the preload according to the manual, or replace the spring.

Emergency Tip: Gently tap the rocker arm while manually cranking to temporarily relieve any sticking.

3. Decreased Drilling Accuracy (Deviated/Oval Hole)

Drilled Hole Position Shifted or Oval

Possible Causes:

Excessive spindle bearing clearance (radial runout >0.02mm).

Insecure drill bit clamping (loose taper shank or drill chuck).

Instable workpiece clamping (deflection caused by vibration).

Solution:

Check spindle radial runout: Measure with a dial indicator. If out of tolerance, adjust the bearing preload.

Replace the drill chuck: Choose a high-precision chuck.

Reinforce the workpiece: Use a pressure plate and shims to prevent shifting during machining. Preventative Measures: Regularly check the cleanliness of the spindle taper to prevent iron chips from affecting positioning.

4. Automatic Feed Failure (No Feed/Uneven Feed)

Automatic Feed Mechanism Malfunction

Possible Causes:

Feed box gears or clutch wear.

Hydraulic feed models: Oil circuit blockage or insufficient oil pressure.

Electrical control failure (CNC models).

Solution:

Mechanical feed box: Disassemble and inspect the gear train and replace broken teeth or worn parts.

Hydraulic feed models:

Check the oil filter for blockage and replace the hydraulic oil.

Adjust the relief valve pressure to the standard specified in the manual (usually 2-3 MPa).

CNC models: Check the servo motor driver alarm code and reset or replace the cable.

Note: If automatic feed fails, do not force manual feed to avoid gear damage!

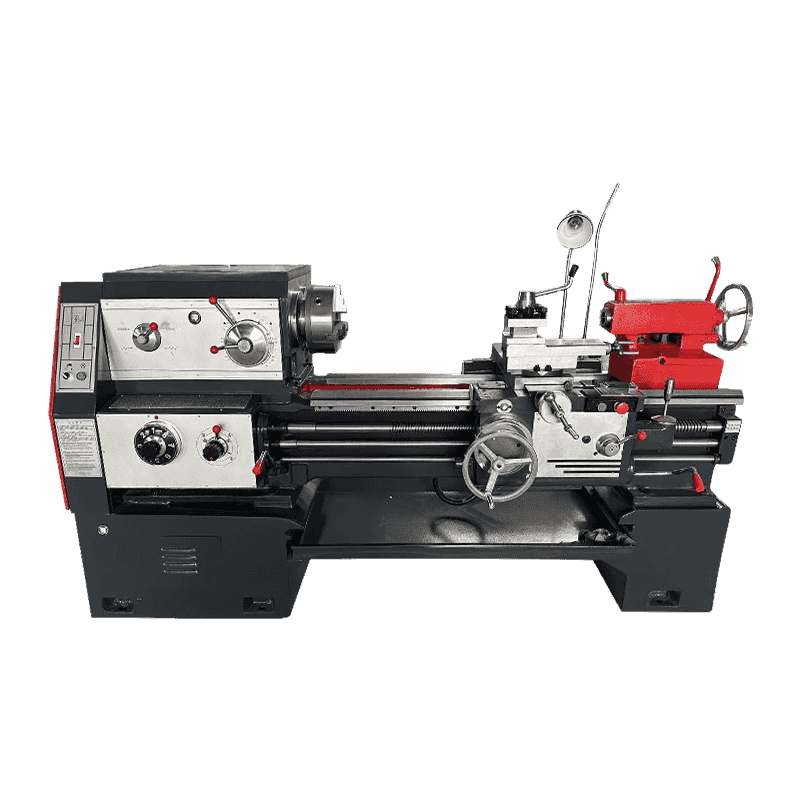

Radial Drilling Machine

Other Common Faults Quick Reference

|

Fault Symptom |

Possible Cause |

Solution |

|

Spindle oil leakage |

Oil seal aging or over-lubrication of the spindle bearings |

Replace oil seal |

|

Worktable wobbles |

Locking mechanism not in place or guide rails worn |

Adjust locking bolts and repair guide rail inserts |

|

Motor overheats and shuts down |

Unstable voltage or belt overtightened |

Check power supply voltage and adjust belt tension |

Radial Drilling Machine Maintenance Tips: 3 Steps to Extend Equipment Life

Daily Maintenance:

Clean away scrap metal and check the lubricant level.

Manually rock all mechanisms before starting the machine to confirm they are not binding.

Monthly Inspection:

Tighten the anchor bolts to prevent loosening due to vibration.

Replace any turbid or deteriorated lubricant.

Annual Overhaul:

Disassemble and clean the spindle housing and replace worn bearings and gears.

Calibrate the column for verticality (error ≤ 0.02 mm/m).

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى