Don't hesitate to contact when you need us!

Why choose CNC single-column vertical lathe? Five major advantages explained

2025.07.15

2025.07.15

Industry News

Industry News

1. The role of CNC single-column vertical lathe

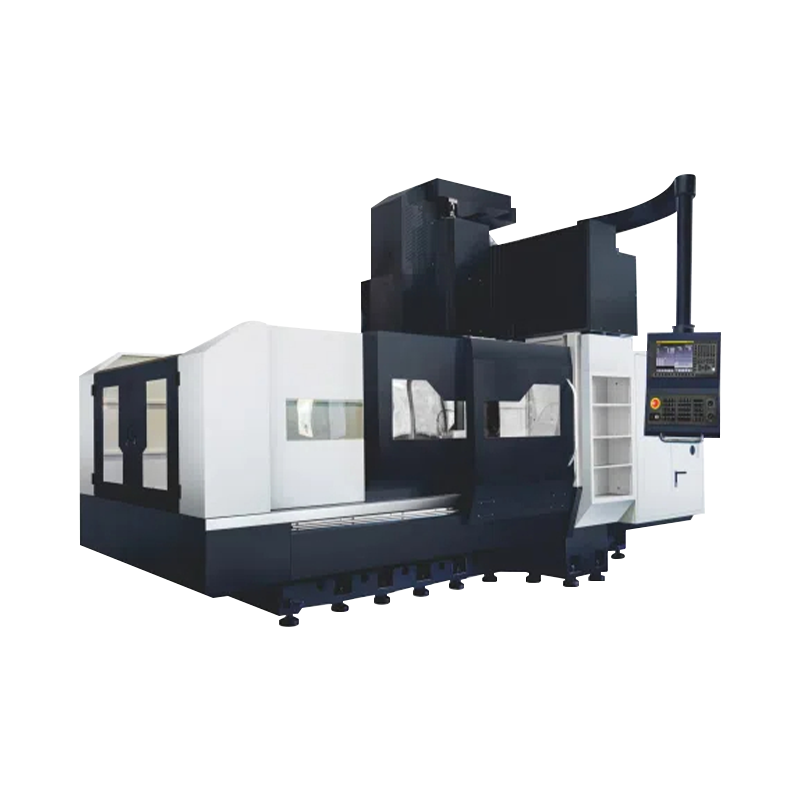

CNC single-column vertical lathe is an important equipment in the field of modern mechanical processing. It integrates computer digital control technology and traditional lathe processing functions, and is specially used for processing large and heavy workpieces. Compared with traditional horizontal lathes, the vertical structure gives it a unique advantage in processing overweight workpieces, and has become an indispensable processing equipment in industries such as aerospace, energy equipment, and heavy machinery.

CNC single-column vertical lathes are mainly used to complete the following types of processing tasks:

Machining of large disc parts: such as turbine discs, gear blanks, flanges, etc.

Heavy-duty rotating body processing: large shaft and cylinder workpieces

Complex surface processing: high-precision cutting of complex three-dimensional surfaces is achieved through the CNC system

High-precision inner/outer circle processing: ensure the dimensional accuracy and form and position tolerance of the workpiece

End face and grooving processing: complete the end face cutting and various groove processing of the workpiece

The working system of the CNC single-column vertical lathe is mainly composed of the following parts:

Mechanical structure: adopts a single-column vertical layout, consisting of a workbench, column, crossbeam, tool holder, etc.

CNC system: as the "brain" of the equipment, it receives processing program instructions and controls each motion axis

Drive system: including servo motors, ball screws, etc., to achieve precise motion control

Measurement system: grating rulers, encoders and other feedback devices ensure processing accuracy

During processing, the workpiece is clamped vertically on the rotating workbench, and the tool moves along the X and Z axes under the control of the CNC system. The material is removed by cutting, and finally the parts of the required shape and size are formed.

2. Five advantages of CNC single-column vertical lathe

- Stable structure, suitable for heavy workpiece processing

Advantages: The vertical layout allows the weight of the workpiece to act directly on the workbench, reducing the risk of cantilever deformation and improving processing stability.

Single-column structure Strong rigidity, suitable for medium to large workpieces (such as wind power flanges, large gears, etc.).

The workbench has a strong load-bearing capacity and can easily carry several tons or even tens of tons of workpieces, avoiding the deformation problem of horizontal lathes caused by excessive workpiece weight.

Easy clamping, especially suitable for disc and cylinder parts with large diameter and moderate height.

- High-precision processing to meet stringent technical requirements

Advantages: CNC system + precision transmission mechanism to ensure micron-level processing accuracy.

CNC system (such as FANUC, SIEMENS) provides high-precision interpolation control to achieve complex contour processing (such as curved surfaces, tapers, threads, etc.).

High-rigidity guide rails + ball screws Reduce vibration and errors, and the repeat positioning accuracy can reach ±0.005mm.

Automatic measurement and compensation functions (such as tool wear compensation and thermal deformation compensation) further improve processing consistency.

- High processing efficiency and high degree of automation

Advantages: CNC programming + automatic tool change system greatly improves production efficiency.

Multi-axis linkage processing, one clamping to complete multiple processes such as turning, milling, drilling, etc., reducing machine change time.

Automatic turret (optional 8-12 stations) supports fast tool change and is suitable for mass production.

Can integrate robot loading and unloading to achieve unmanned production and reduce labor costs.

- Strong adaptability to meet diversified processing needs

Advantages: Applicable to a variety of materials and industries, with strong flexible production capabilities.

Processable materials: steel, cast iron, aluminum alloy, titanium alloy, composite materials, etc.

Widely used in the industry:

Energy industry (wind power flange, nuclear power components)

Aerospace (engine casing, turbine disc)

Rail transportation (wheels, brake discs)

Military manufacturing (large shafts, housing parts)

Support customized configuration (such as adding milling head, Y-axis function) to meet special process requirements.

- Easy operation and low maintenance cost

Advantages: Intelligent CNC system + modular design, reducing the difficulty of use and maintenance cost.

Graphical programming (such as CAD/CAM integration) simplifies the programming process of complex parts.

Fault self-diagnosis function, quickly locate problems and reduce downtime.

Modular structure design, key components (such as spindles and guides) are easy to replace, extending the life of the equipment.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى