Don't hesitate to contact when you need us!

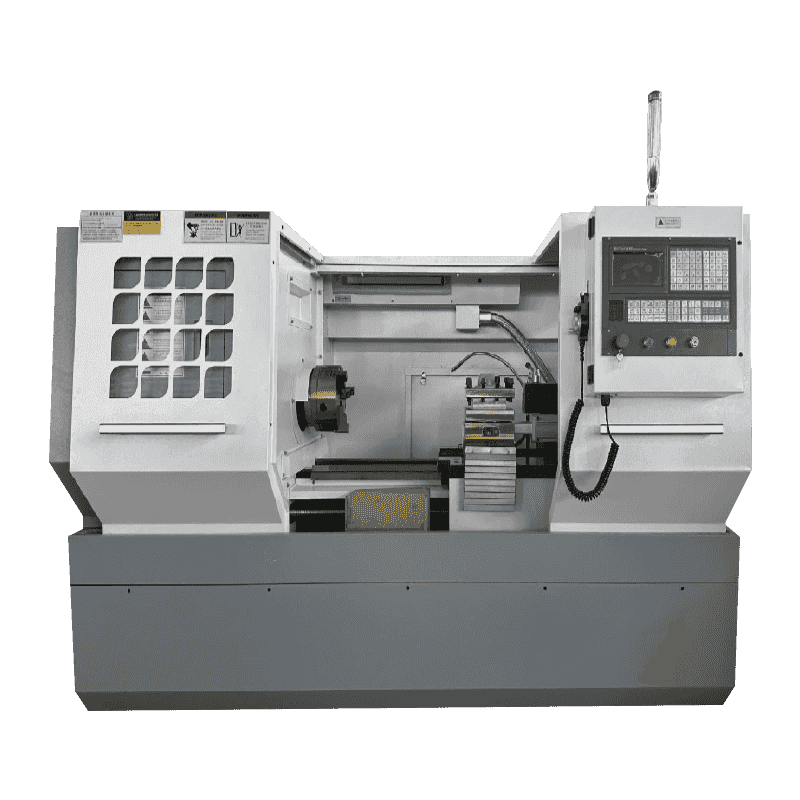

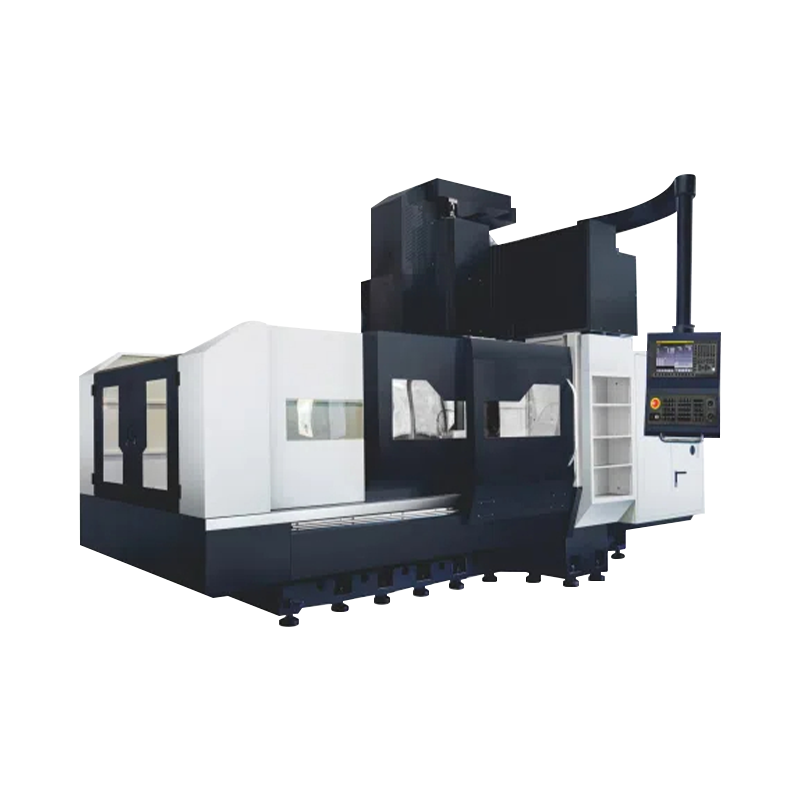

Drawout Coolant Tank Horizontal Turning Center: Innovative Solution for Precision Machining

2025.07.09

2025.07.09

Industry News

Industry News

Content

1. Working Principle of the Product

The innovative separate cooling system design of the drawout coolant tank horizontal turning center has changed the structural concept of the traditional turning center. This advanced equipment completely separates the cutting fluid storage system from the machine tool body, and achieves a perfect combination of efficient cooling and ultimate protection through an external drawable coolant tank. The horizontal turning center with a drawout coolant tank separates the cutting fluid reservoir from the machine tool body, effectively avoiding the potential corrosion risk of the cutting fluid on the precision parts of the machine tool, and greatly reducing the machine tool failure rate caused by cutting fluid leakage. The independent water tank not only enhances the overall protection performance of the machine tool, but also keeps the machine tool body dry and clean, extending the service life of the equipment.

Core working principle——

Separate cooling system: The coolant tank adopts a fully enclosed independent design, connected to the main machine through a quick connector, completely isolating the contact between the cutting fluid and the precision parts of the machine tool

Negative pressure circulation technology: The built-in high-pressure pump group (pressure can reach 20Bar) cooperates with the intelligent flow control system to achieve accurate delivery and recovery of coolant

Three-stage filtration device: Contains coarse filtration, fine filtration and magnetic filtration units to ensure the purity of the coolant

Temperature control module: Equipped with PID temperature control system and heat exchanger to maintain the constant temperature of the coolant

2. Product advantages

This innovative design brings unprecedented performance improvement and operation and maintenance convenience to modern precision machining, showing significant advantages in multiple dimensions.

Comparison of core technology advantages:

|

Performance indicators |

Traditional horizontal turning center |

Extractable coolant tank model |

|

Anti-corrosion performance |

Coolant contacts the machine tool structure |

Complete physical isolation |

|

Failure interval |

800-1000 hours |

2500+ hours |

|

Liquid replacement efficiency |

4-6 hours/time |

1.5 hours/time |

|

Accuracy retention |

Calibration required every 6 months |

Accuracy maintained for 12 months |

|

Energy consumption level |

Standard level |

Cooling system saves 30% energy |

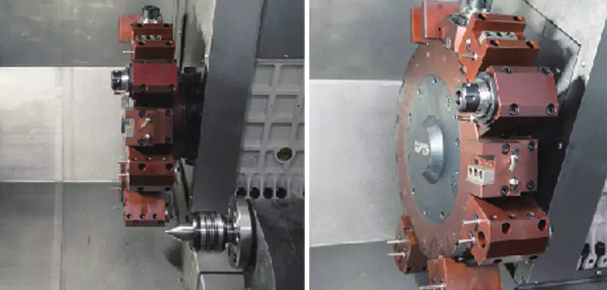

3. Technological breakthrough of chip removal system

The advanced chip removal system is another major technical highlight of this equipment. Its innovative design perfectly solves the problem of chip management in precision machining.

Technical analysis of chip removal system——

Multi-level sorting mechanism: automatic chip classification through vibration screening + pneumatic conveying

Intelligent sensing technology: built-in visual system monitors chip morphology in real time and automatically adjusts chip removal parameters

Low-noise operation design: hydraulic damping + sound-absorbing materials are used, and the working noise is ≤68dB

Large-capacity processing: the maximum chip removal volume reaches 150kg/h, which is suitable for heavy-duty cutting conditions

Chip removal process——

Negative pressure collection in cutting area → primary magnetic separation → vibration screening and grading → spiral conveying to chip collection vehicle → automatic alarm prompt cleaning

4. Usage specifications and maintenance points

To ensure the best performance of the equipment and extend its service life, scientific operation and maintenance procedures must be followed.

- Pre-startup inspection:

Confirm that the coolant tank is fully in place and locked

Check that the chip removal pipe is not deformed or blocked

Verify that the liquid level sensor functions normally

- Monitoring during operation:

Coolant temperature is controlled at 25±2℃

Chip removal system load current ≤80% of rated value

Abnormal vibration (>2mm/s) immediately stop the machine for inspection

- Daily maintenance:

Clean the chip removal car daily (residue <1/3 volume)

Check the filter pressure difference weekly (>0.3MPa needs to be replaced)

Check the coolant concentration monthly (maintained at 4-6%)

Common troubleshooting:

|

Fault phenomenon |

Possible cause |

Solution |

|

Coolant alarm |

Level sensor contaminated |

Clean probe with alcohol cotton |

|

Poor chip removal |

Chip wrapped around spiral shaft |

Reverse for 10 seconds and then forward |

|

Abnormal noise |

Bearing lacks oil |

Add high temperature extreme pressure grease |

|

Insufficient flow |

Filter clogged |

Replace filter element (pressure difference > 0.4MPa) |

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى