Don't hesitate to contact when you need us!

Working Principle of Z3050X16/1 Radial Drilling Machine

2025.05.25

2025.05.25

Industry News

Industry News

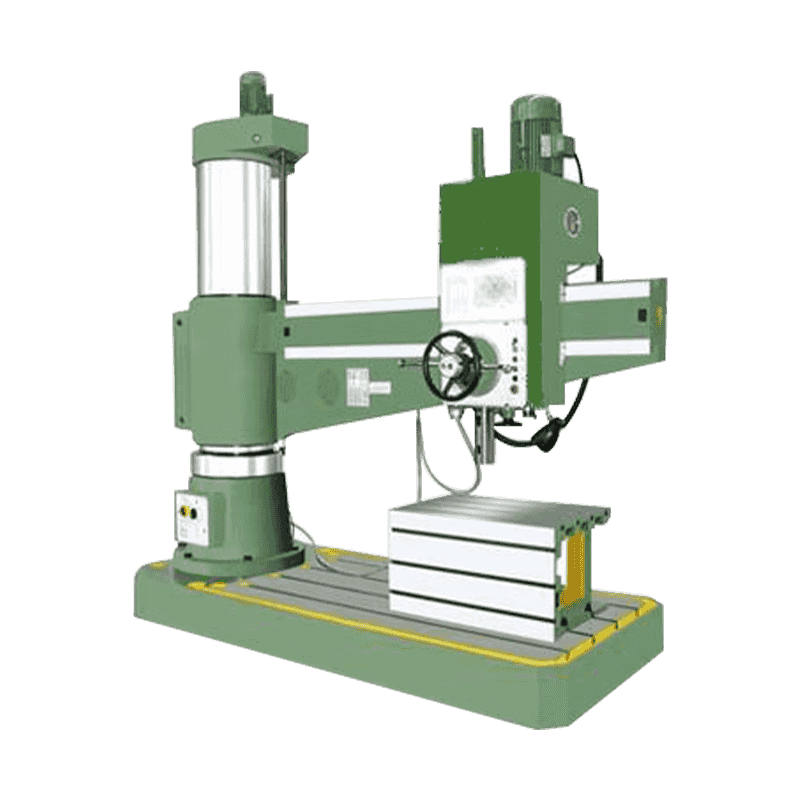

Z3050X16/1 Radial Drilling Machine uses four motors to work together: the spindle motor (M1) drives the spindle rotation and feed movement, and the hydraulic system realizes the spindle forward and reverse rotation, neutral and speed control. The rocker arm lifting motor is responsible for vertical movement of the rocker arm, and the lifting direction is controlled by contactors KM2 and KM3. The pressure oil provided by the hydraulic pump motor realizes the automatic process of rocker arm release-lifting-clamping. M3 also undertakes the clamping function of the column and the spindle box, and ensures the processing stability through the hydraulic diamond block mechanism.

The hydraulic pre-selection speed change mechanism realizes 16 levels of spindle speed and 16 levels of feed. The parameters can be switched without stopping, saving 30% of auxiliary time. The machine uses a hydraulically driven diamond block clamping mechanism with a clamping force of more than 2000N to ensure the rigid locking of the spindle box, rocker arm and outer column during processing and reduce the impact of vibration on precision. The hydraulic clamping device is automatically released before the rocker arm is raised or lowered, and the re-clamping action is completed within 0.5 seconds after it is in place.

The electrical system is equipped with grating scale feedback and PLC control module, combined with double interlocking circuits to achieve precise positioning of the rocker arm lifting and lowering. The depth control of the spindle is achieved through the dial fixed-range cutting function, and each scale corresponds to a feed accuracy of 1mm.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى