Don't hesitate to contact when you need us!

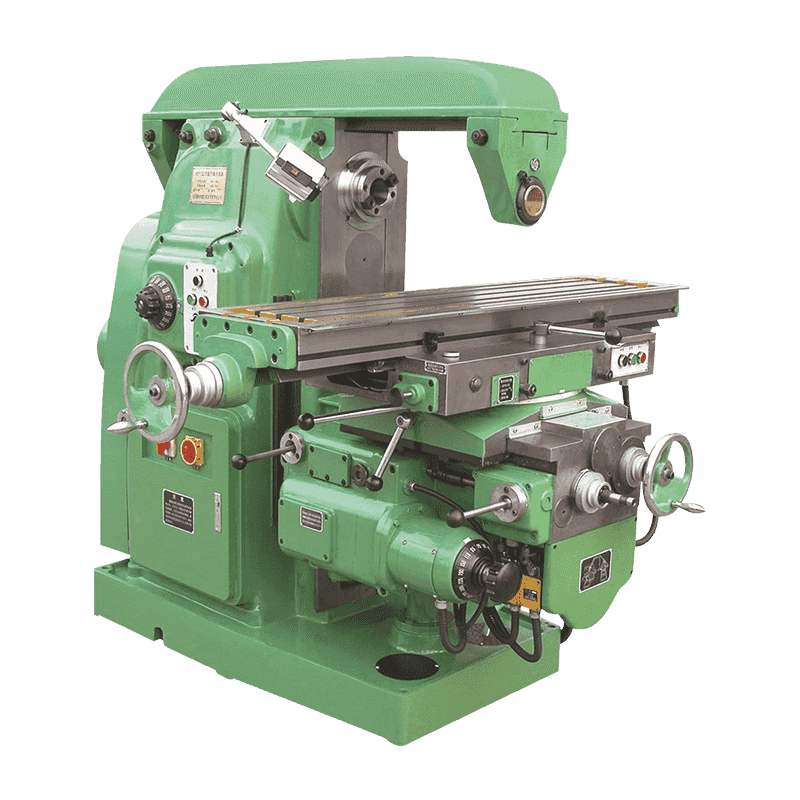

What is a Vertical Milling Center?

2026.02.20

2026.02.20

Industry News

Industry News

Content

What is a Vertical Milling Center?

A vertical milling center (VMC) is a computer numerically controlled (CNC) machine used for precise and efficient machining operations. It features a vertically oriented spindle that holds the cutting tool, allowing it to cut materials such as metal, plastic, and composites in a variety of shapes and sizes. VMCs are commonly used in industries that require high precision, such as aerospace, automotive, and medical device manufacturing.

Key Features of a Vertical Milling Center

- Vertical Spindle Orientation: The spindle moves vertically, allowing precise control over the cutting process, making it ideal for detailed and complex parts.

- Computer Numerical Control (CNC): CNC technology provides automated control of the machine, ensuring repeatability and reducing human error.

- Tool Changer: Most VMCs are equipped with an automatic tool changer, which reduces setup time by enabling quick tool swaps during the machining process.

- High-Speed Cutting: VMCs are capable of high-speed machining, allowing for faster production times and improved efficiency.

- Precision and Accuracy: The machine's precise control ensures high accuracy, even for intricate and delicate parts.

Advantages of Using a Vertical Milling Center

Vertical milling centers offer several advantages over traditional machining methods. These benefits make them an essential tool for precision machining in various industries:

- Increased Efficiency: With automated CNC control and tool changing capabilities, VMCs significantly reduce manual labor, resulting in faster cycle times and higher production rates.

- Enhanced Precision: The precise control offered by VMCs allows for high-quality, intricate parts with tight tolerances, making them ideal for industries requiring accuracy, such as aerospace and medical manufacturing.

- Versatility: VMCs are capable of performing a wide range of machining operations, including drilling, milling, tapping, and boring, all on a single platform.

- Reduced Setup Time: The ability to quickly change tools and programs reduces the time spent setting up and retooling the machine for different tasks, making it a cost-effective choice for small and medium production runs.

- Lower Labor Costs: The automation and precision provided by VMCs reduce the need for skilled labor, allowing manufacturers to cut costs while maintaining high product quality.

Applications of Vertical Milling Centers

Vertical milling centers are versatile machines used in various industries due to their ability to handle multiple operations with high precision. Some of the key applications include:

- Aerospace: Manufacturing of complex parts such as turbine blades, housings, and precision fasteners.

- Automotive: Production of engine components, transmission parts, and other high-precision automotive parts.

- Medical Devices: Creation of medical implants, surgical instruments, and other precision components used in healthcare.

- Electronics: Manufacturing of circuit boards, connectors, and enclosures for electronic devices.

Common FAQs About Vertical Milling Centers

- 1. What types of materials can be machined with a vertical milling center? VMCs can machine a wide range of materials, including metals (steel, aluminum, titanium), plastics, and composites.

- 2. How fast can a vertical milling center machine parts? VMCs can operate at high speeds, typically ranging from 3,000 to 12,000 RPM, depending on the material being machined and the tool used.

- 3. What is the maximum size of parts that can be machined on a vertical milling center? The size depends on the specific machine model, but most VMCs can handle parts up to 1 meter in length, width, and height.

- 4. Is operator training required for using a vertical milling center? Yes, operators need to be trained in CNC programming and machine operation to ensure safe and efficient use of the machine.

- 5. How often does a vertical milling center need maintenance? Regular maintenance includes lubrication of moving parts, cleaning of the machine bed, and checking for tool wear. Scheduled servicing typically occurs every 6-12 months, depending on usage.

- 6. Can a vertical milling center be used for both rough and finish machining? Yes, VMCs can be programmed for both roughing and finishing operations, making them versatile for various stages of machining.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى