Don't hesitate to contact when you need us!

What are the advantages of a chuck turret CNC lathe?

2025.11.19

2025.11.19

Industry News

Industry News

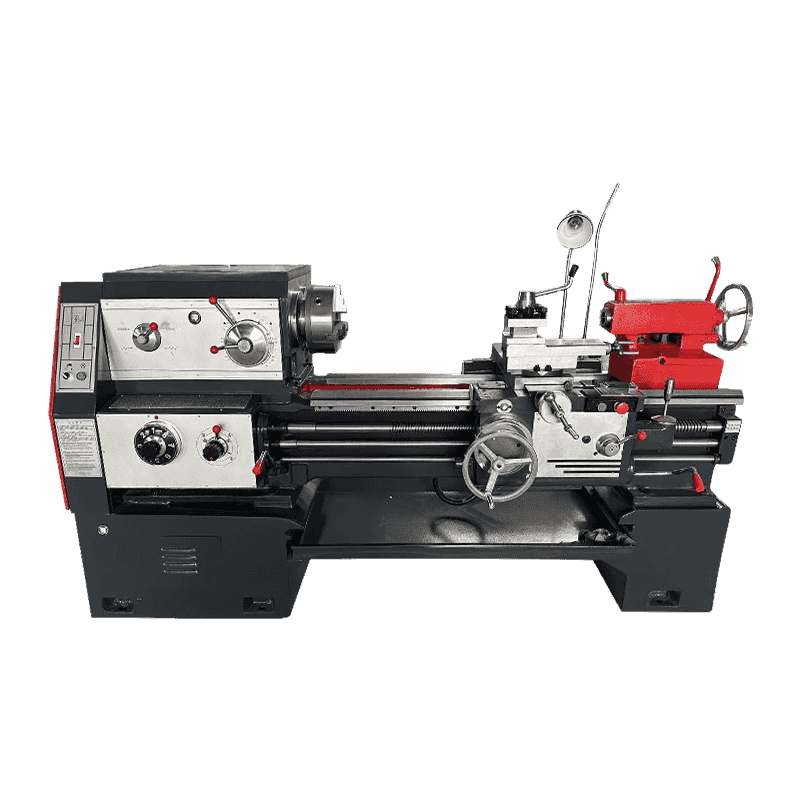

In the machining industry, the choice of CNC lathe directly determines machining efficiency, product accuracy, and cost control. In recent years, chuck turret CNC lathes have become increasingly popular among various machining companies, capable of handling almost anything from small-batch customization to large-scale automated production. So, what unique advantages do these lathes offer that make them a top choice for many companies upgrading their equipment?

Content

- 1 1. High-efficiency multi-station machining capabilities

- 2 2. Stable Clamping, Higher Machining Precision

- 3 3. Adaptable to Complex Part Machining

- 4 4. High Processing Efficiency, Suitable for Mass Production

- 5 5. Strong Automation, Intelligence, and Expandability

- 6 6. Compact Structure, Small Footprint, and Convenient Maintenance

1. High-efficiency multi-station machining capabilities

The most obvious feature of a chuck turret CNC lathe is its multi-station tool turret. Compared to traditional single-tool-turret models, it can complete various processes such as turning, grooving, drilling, and tapping without changing equipment or frequent manual tool changes. The turret's rapid positioning and short tool change time significantly reduce auxiliary time during machining. This advantage is particularly prominent in mass production, significantly improving output efficiency per unit time and reducing the frequency of manual intervention.

2. Stable Clamping, Higher Machining Precision

Chuck turret CNC lathes utilize a rigid and stable chuck structure, a crucial foundation for machining high-precision parts. The chuck provides more uniform and stable clamping force, keeping the workpiece stable during high-speed rotation, thus reducing vibration, minimizing runout, and improving dimensional accuracy and surface roughness. Combined with the high-precision lead screw and guide rails of the CNC system, the overall precision and stability are significantly higher than traditional lathes, making it ideal for machining demanding shaft, sleeve, and disc parts.

3. Adaptable to Complex Part Machining

Chuck turret CNC lathes not only perform conventional turning tasks but can also achieve milling, drilling, and other composite machining capabilities by configuring a powered turret, further expanding their application range. For parts with complex shapes and numerous processes, it can complete multiple processes in a single clamping, reducing deviations caused by repeated positioning and achieving higher machining consistency. Enterprises can leverage this to reduce equipment investment, avoid process chain redundancy caused by multi-machine operation, and improve the workshop's flexible production capabilities.

4. High Processing Efficiency, Suitable for Mass Production

In the context of large-volume order demands, the cycle time of equipment directly impacts delivery time. The chuck turret lathe's rapid tool change, programmed automated machining, and stable long-term operation make it ideal for continuous production in industries such as automotive parts, hydraulic components, and hardware products. The multi-station structure shortens tool change intervals, the high-speed spindle improves cutting efficiency, and the stable chip removal and cooling system ensures that the machine tool does not degrade in efficiency during long-term processing.

5. Strong Automation, Intelligence, and Expandability

Chuck turret lathes typically have excellent automation compatibility, easily integrating with robotic arms, gantry robots, loading and unloading systems, and vision inspection systems to achieve unmanned machining. Through intelligent monitoring by the CNC system, data such as cutting load, temperature changes, and machining cycle time can be recorded in real time, helping companies improve lean management capabilities. These intelligent functions not only reduce labor costs but also increase equipment utilization, further enhancing the company's competitiveness.

6. Compact Structure, Small Footprint, and Convenient Maintenance

Compared to some complex composite machine tools, the chuck turret type has a compact structure and occupies less space, making it suitable for companies with limited workshop space. Its electrical layout and lubrication system are designed with greater modularity, making maintenance and upkeep easier. The highly reliable and stable structural design also reduces equipment failure rates, ensuring a stable and continuous machining process.

The key to the chuck turret CNC lathe becoming a mainstay equipment for companies in various industries lies in its combination of high efficiency, multi-functionality, high precision, and intelligent expandability. Whether machining complex parts or mass production, it can provide strong capacity and excellent machining quality.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى