Don't hesitate to contact when you need us!

Vertical Lathes vs. Horizontal Lathes: Which is Right for You?

2025.12.16

2025.12.16

Industry News

Industry News

In the machine tool industry, vertical lathes and horizontal lathes are the two most common types, and they have significant differences in design, application, and working principles. For many manufacturers, choosing the right lathe for their production needs is crucial. So, which is better for you: a vertical lathe or a horizontal lathe?

1. Working Principles of Vertical and Horizontal Lathes

First, let's look at the working principles of these two types of lathes. Both vertical and horizontal lathes belong to the turning machine tool category, but they differ in the position of their worktable and tools.

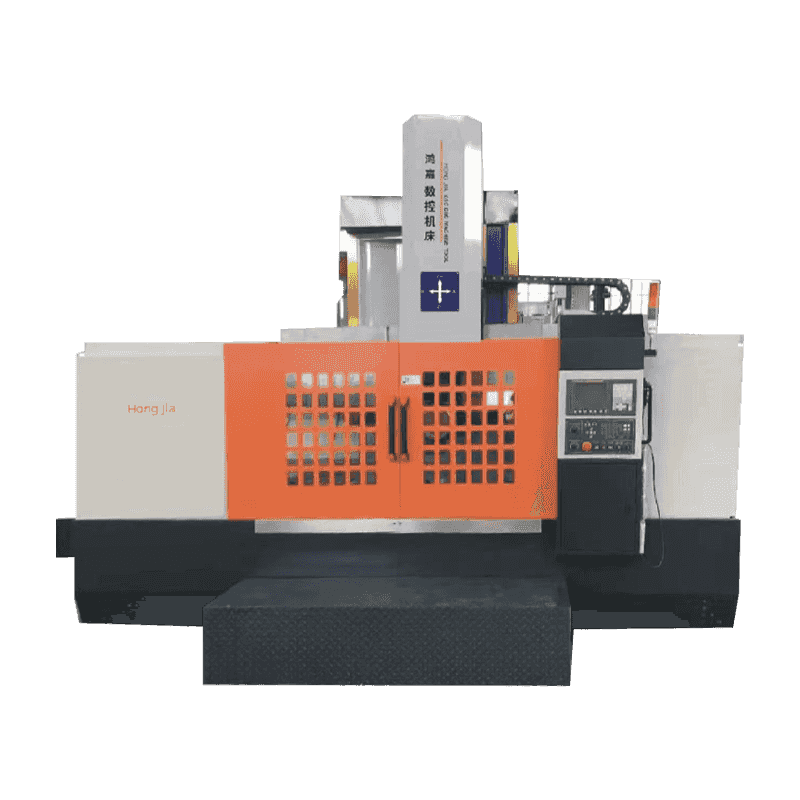

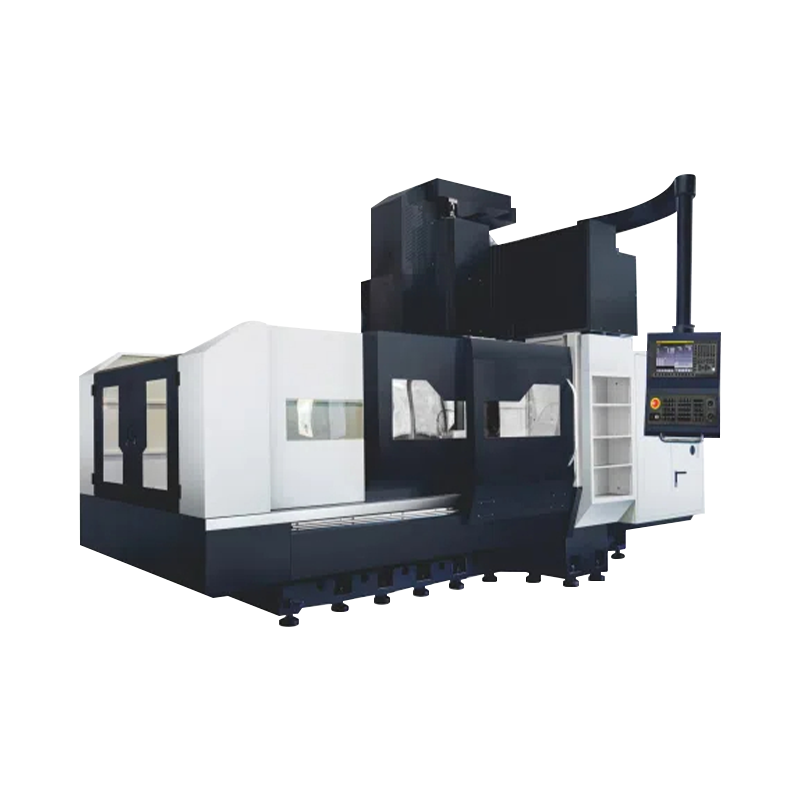

Vertical Lathe: In a vertical lathe, the workpiece is usually mounted on a vertically oriented worktable, and the tool performs cutting along the vertical axis. This structure allows heavy workpieces to be directly mounted on the worktable, reducing the complexity of clamping and tool changes. Vertical lathes are typically suitable for processing larger and heavier workpieces.

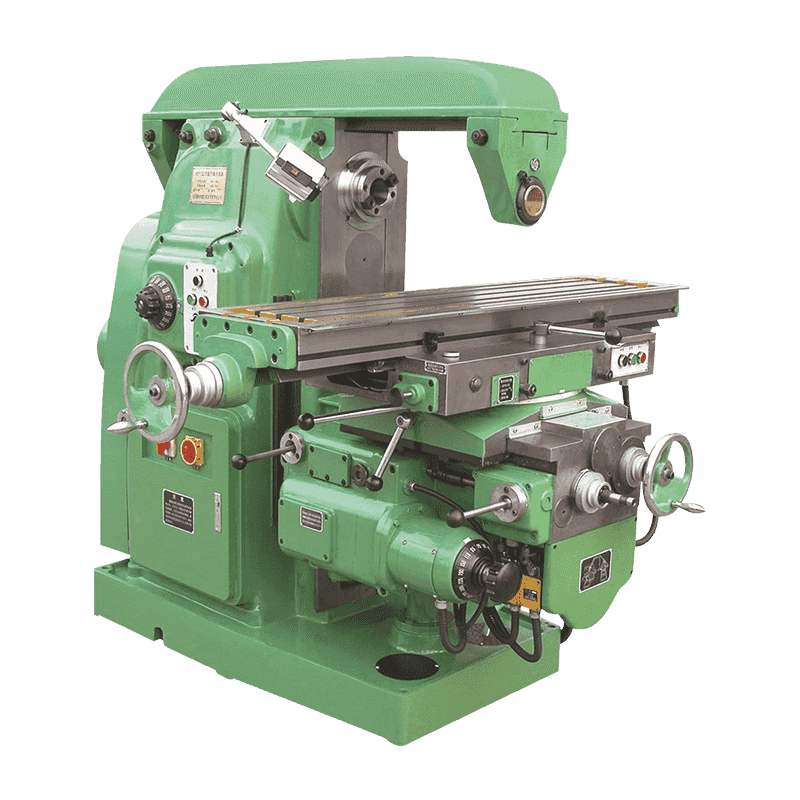

Horizontal Lathe: In a horizontal lathe, the workpiece is mounted on a horizontal worktable, and the tool performs cutting along the horizontal axis. Horizontal lathes are suitable for smaller or medium-sized workpieces, and their design is generally more suitable for precision machining and mass production.

2. Advantages and Disadvantages of Vertical and Horizontal Lathes

Each type of lathe design has its unique advantages and disadvantages. Understanding these pros and cons will help you make a more informed decision when choosing.

Advantages of Vertical Lathes:

Suitable for large workpieces: Due to the structural characteristics of vertical lathes, processing large and heavy workpieces is more convenient. They can handle large diameter or complex machining tasks and are easy to clamp.

High stability: Due to their design structure, vertical lathes have high stability during processing, especially under heavy loads.

High machining accuracy: Suitable for high-precision machining, such as precision external and internal diameters, milling, etc.

Convenient operation and maintenance: Because the worktable is placed vertically, operators can easily observe the workpiece and the machining process, improving work efficiency and safety.

Disadvantages of Vertical Lathes:

Limited machining range: Compared to horizontal lathes, vertical lathes have a smaller machining range, especially for smaller, more delicate workpieces, and may not be as flexible as horizontal lathes.

Larger space requirement: Due to the design of the worktable, vertical lathes usually occupy a larger area.

Advantages of Horizontal Lathes:

Suitable for machining small and medium-sized workpieces: Horizontal lathes are suitable for smaller workpieces, especially for mass production. This gives them high flexibility in precision machining.

More suitable for detailed machining: Horizontal lathes generally have higher machining accuracy, especially when performing complex details, providing better workpiece surface quality.

Space-saving: The worktable of a horizontal lathe is lower, occupying less space than a vertical lathe, making it more suitable for workspaces with limited space.

Disadvantages of Horizontal Lathes:

Difficult to machine large workpieces: Horizontal lathes are not as convenient as vertical lathes for machining large workpieces, especially those requiring greater rigidity support.

More complex operation and maintenance: Operation and maintenance may be slightly more complex than vertical lathes, especially when handling large workpieces.

3. Application Comparison of Vertical and Horizontal Lathes

Different types of lathes are suitable for different machining tasks. The following are some typical applications in actual production:

| Feature | Vertical Lathe | Horizontal Lathe |

| Workpiece Size | Suitable for large, heavy workpieces | Suitable for medium and small workpieces |

| Processing Accuracy | High precision, suitable for precision machining | High precision, especially suitable for intricate details in precision machining |

| Space Occupation | Occupies more space, suitable for large workshops | Occupies less space, more suitable for limited space environments |

| Production Efficiency | Suitable for batch production, especially efficient for large workpieces | Suitable for fine machining and small batch production |

| Ease of Operation | Simple operation, relatively easy to maintain | More complex operation, maintenance may be relatively troublesome |

4. Which lathe is right for you?

The choice between a vertical lathe and a horizontal lathe ultimately depends on your specific production needs.

If you primarily process large or heavy workpieces, a vertical lathe may be more suitable. It offers greater stability and better support, making it ideal for machining large-diameter and complex workpieces.

If you require higher precision, detailed machining, and mass production, a horizontal lathe might be a better choice. It is suitable for small and medium-sized workpieces, and excels particularly in precision machining and high-volume production.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى