Don't hesitate to contact when you need us!

Operating Techniques for Vertical Lathes: Five Methods to Improve Machining Accuracy and Efficiency

2025.12.23

2025.12.23

Industry News

Industry News

Vertical lathes, as important processing equipment in modern manufacturing, are widely used in aerospace, automotive, energy, and heavy machinery industries. Their unique structure makes them suitable for processing large and heavy workpieces, and they offer high efficiency and precision. To maximize the processing effectiveness of a vertical lathe, operators must master some basic operating techniques to ensure high precision and efficiency during the machining process.

This article will introduce five vertical lathe operating techniques to help you improve processing accuracy and efficiency, ensuring optimal results every time.

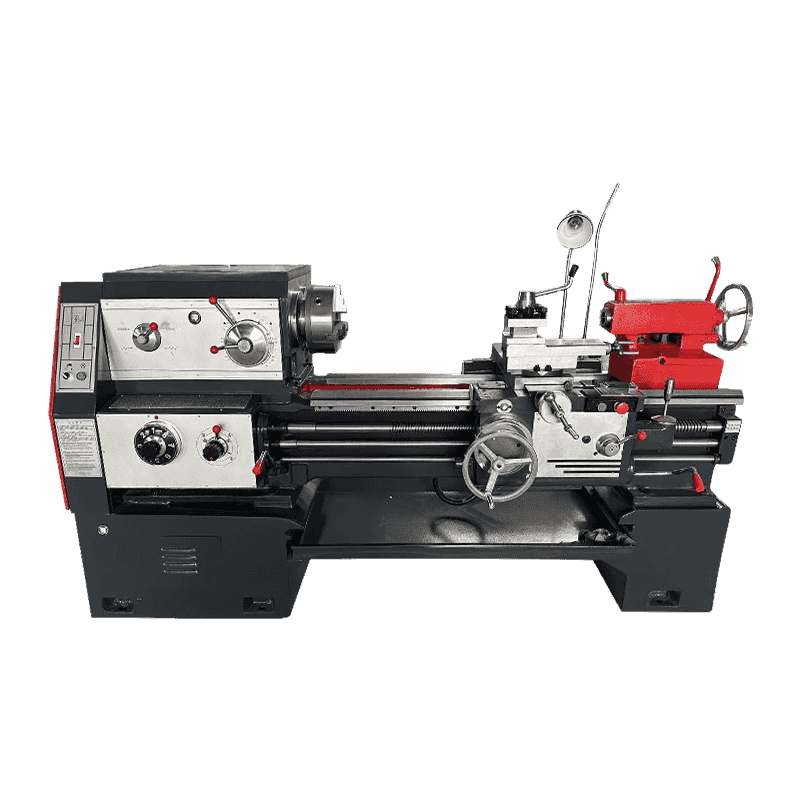

1. Selecting the Right Tools and Cutting Parameters

The processing accuracy and efficiency of a vertical lathe largely depend on the selection of tools and the setting of cutting parameters. Different materials and workpiece shapes require different tools and cutting conditions. Improper tool selection or unreasonable cutting parameter settings can lead to substandard processing quality or even damage to the equipment.

Operating Techniques:

Select appropriate tool materials: Choose the right tool based on the workpiece material, such as cast iron, steel, or alloy materials. Carbide tools are suitable for processing hard materials, while high-speed steel tools are suitable for medium-hardness materials.

Adjust cutting parameters: Adjust the cutting speed, feed rate, and cutting depth according to the processing requirements. Appropriate cutting parameters can reduce heat buildup, reduce tool wear, and improve processing efficiency.

Through reasonable tool selection and cutting parameter settings, you can effectively improve the processing accuracy and production efficiency of your vertical lathe.

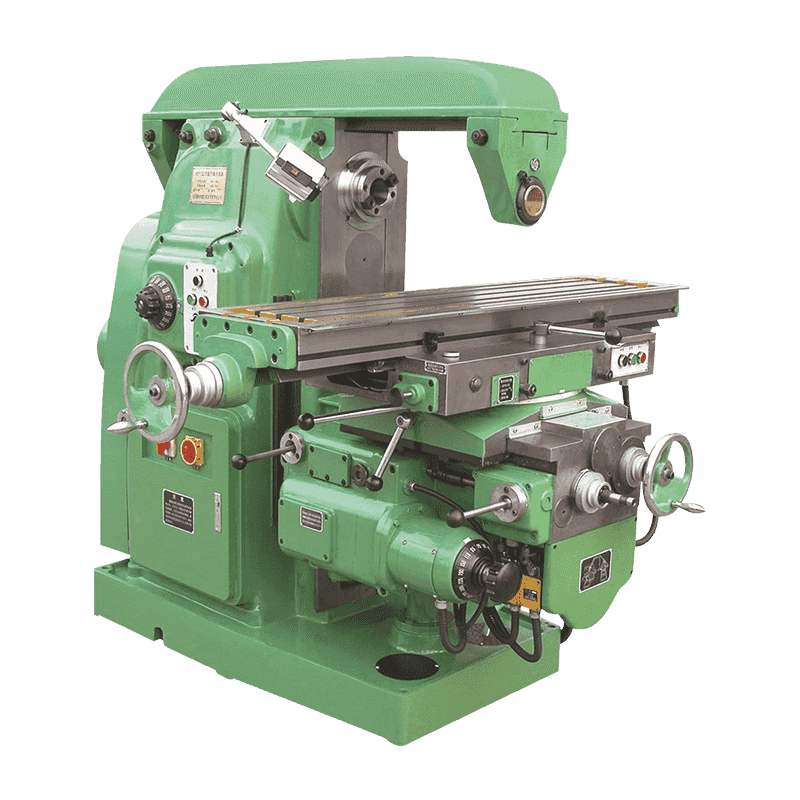

2. Ensuring Correct Workpiece Clamping and Positioning

When using a vertical lathe, workpiece clamping and positioning are crucial factors in ensuring processing accuracy. If the workpiece loosens or shifts during processing, it will affect the processing accuracy and may even cause serious errors.

Operating Techniques:

Use appropriate fixtures: Select appropriate fixtures based on the size and weight of the workpiece, such as hydraulic clamps, three-jaw chucks, or four-jaw chucks, to ensure that the workpiece is stable and secure during processing.

Center the workpiece: Use precision tools to ensure that the workpiece is centered on the lathe, avoiding processing errors caused by inaccurate centering. Workpiece centering is especially critical in high-precision machining. Using Support Tools: For long shafts or large workpieces, use a tailstock or support stand to reduce bending and vibration of the workpiece and ensure stability.

Ensuring the workpiece is stable and precisely centered can effectively improve the accuracy and quality of vertical lathe machining.

3. Controlling Vibration and Thermal Deformation

Vibration and heat generated during machining are two common problems that affect the accuracy of vertical lathe machining. Vibration not only affects surface finish but also leads to wear of the tool and workpiece. Thermal deformation can cause changes in the size and shape of the workpiece.

Operating Techniques:

Reducing Vibration: Use rigid tools and tool holders to prevent the tool from rebounding or vibrating during cutting. Strengthen the machine tool's infrastructure to ensure the stability of the working environment.

Optimizing Cutting Conditions: By setting reasonable cutting speed, feed rate, and cutting depth, reduce the vibration and heat accumulation generated during machining, and avoid the impact of thermal expansion on workpiece accuracy.

Use of Coolant: Using coolant with appropriate flow rate and pressure not only helps to cool down but also reduces friction, extends tool life, and maintains the dimensional stability of the workpiece.

Effectively controlling vibration and thermal deformation is an important step in ensuring the accuracy of vertical lathe machining.

4. Regular Equipment Maintenance and Calibration

Equipment maintenance and calibration are crucial for the long-term efficient operation of vertical lathes. If the machine tool's accuracy is unstable or certain components are severely worn, it may lead to machining errors and affect production efficiency.

Operating Techniques:

Regularly Check Machine Tool Accuracy: Regularly check the accuracy of the spindle, guide rails, and lead screws of the vertical lathe to ensure that all parameters of the machine tool are within the standard range. If deviations are found, calibration should be performed promptly.

Cleaning and Lubrication: Regularly clean all components of the vertical lathe, especially the guide rails and spindle. Maintain a good lubrication system to reduce friction and wear and extend equipment life.

Check Tool Wear: Replace severely worn tools promptly to avoid reduced machining accuracy due to tool damage.

Through regular equipment maintenance and calibration, the vertical lathe can maintain a good machining state, reduce equipment failures, and improve production efficiency.

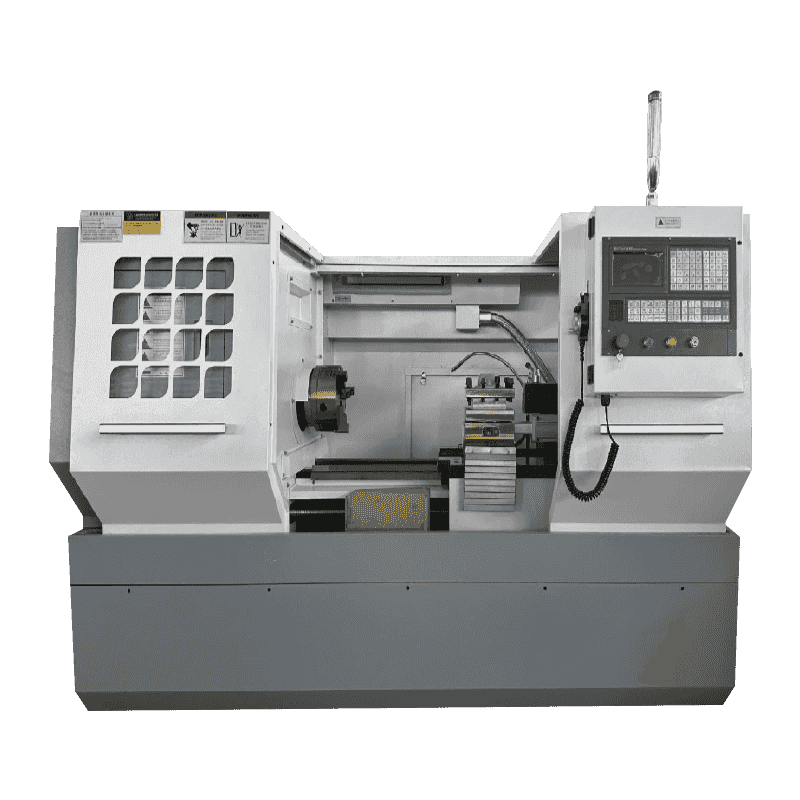

5. Enhancing the Application of CNC Technology

Modern vertical lathes are typically equipped with advanced CNC systems, enabling precise automated operation and efficient machining. By optimizing CNC programs, you can significantly improve machining accuracy and production efficiency.

Operating Techniques:

Optimize CNC programs: Based on the characteristics of the workpiece and processing requirements, design a reasonable machining path to reduce machine idle time and unnecessary movements. Ensure the smooth operation of the CNC program to avoid stuttering or errors.

Utilize automation functions: If the vertical lathe is equipped with functions such as automatic tool changing and automatic workpiece loading and unloading, rationally using these automated tools can reduce manual operation and improve production efficiency.

Real-time monitoring and adjustment: Utilize the real-time monitoring function of the CNC system to detect any abnormalities during the machining process and adjust parameters in a timely manner to ensure stable machining accuracy.

By rationally applying CNC technology, you can not only improve the machining efficiency of the vertical lathe but also enhance the overall automation level of the production line.

Through the above five operating techniques—selecting appropriate tools and cutting parameters, ensuring workpiece clamping and positioning, controlling vibration and thermal deformation, regular equipment maintenance and calibration, and enhancing the application of CNC technology—you will be able to significantly improve the machining performance of the vertical lathe, ensuring high-precision and high-efficiency production. Mastering these techniques will not only improve production efficiency but also reduce the failure rate and ensure the long-term stable operation of the machine tool.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى