Don't hesitate to contact when you need us!

What are the functions and advantages of universal lifting table milling machine in the industrial field?

2025.07.04

2025.07.04

Industry News

Industry News

1. The role of universal lifting table milling machine

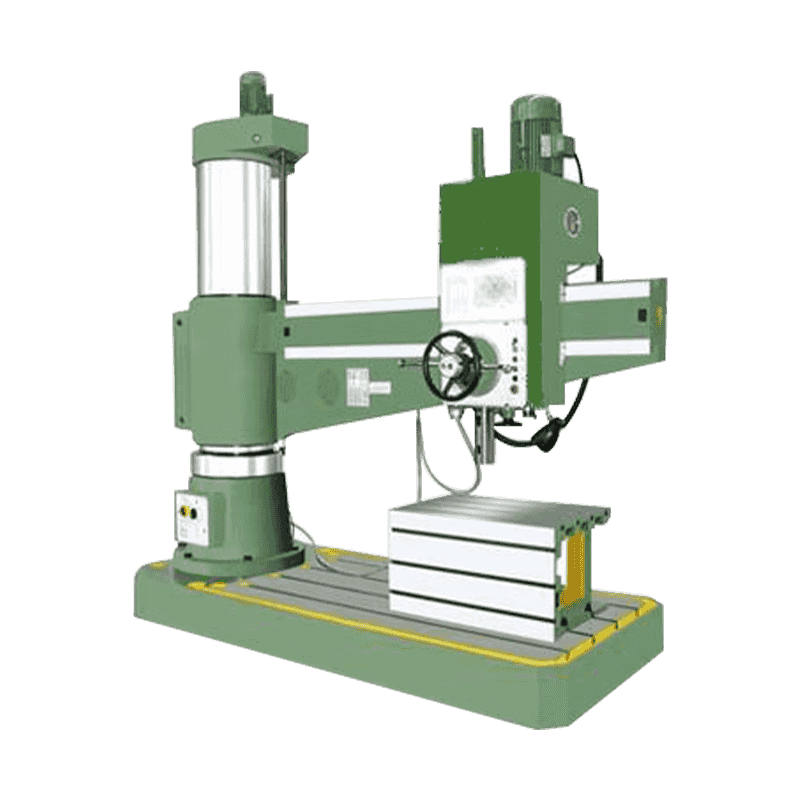

The universal lifting table milling machine is a high-rigidity, high-precision metal cutting equipment. The product design fully considers the dual requirements of modern manufacturing industry for processing efficiency and quality. The machine tool adopts high-quality cast iron bed, which has been precisely aged to ensure excellent stability under heavy-load cutting conditions. The wide range of feed speed adjustment enables it to meet the high-efficiency requirements of rough machining and achieve the surface quality requirements of fine machining.

The machine tool has strong rigidity, a wide feed speed range, and can withstand heavy-load chip removal. The spindle taper hole can be directly installed or installed through accessories with various cylindrical milling cutters, arc milling cutters, forming milling cutters, face milling cutters and other tools. It is suitable for processing planes, bevels, grooves, holes, etc. of various parts. It is an ideal processing equipment for machinery manufacturing, molds, instruments, meters, automobiles, motorcycles and other industries.

2. Advantages of universal lifting table milling machine

- The worktable has three types of manual feeding, mobile feeding and mobile fast feeding in the X/Y/Z direction. The feeding speed can meet different processing requirements; fast feeding can make the workpiece reach the processing position quickly, which is convenient and fast to process and shorten the non-processing time.

- The main components such as the base, fuselage, worktable, slide, lifting slide, etc. are all cast with high-strength materials and are artificially aged to ensure the long-term stability of the machine tool.

- The lubrication device can force lubricate the longitudinal, transverse, longitudinal and vertical screws and guide rails to reduce the wear of the machine tool and ensure the efficient operation of the machine tool; at the same time, the cooling system changes the flow rate of the coolant by adjusting the nozzle to meet different processing needs.

- The spindle bearing of the machine tool is a tapered roller bearing. The spindle adopts a three-support structure. The spindle system has good rigidity and strong load-bearing capacity. The spindle adopts energy-consuming braking, with large braking torque and quick and reliable stopping.

- The machine tool design conforms to the principles of ergonomics and is easy to operate; the operation panel adopts a figurative symbol design, which is simple and intuitive.

- The horizontal rotation angle of the worktable is ±45°, which expands the processing range of the machine tool. The main transmission part and the worktable feed part adopt a gear transmission structure, which has a wide speed regulation range and convenient and fast speed change.

- The three-way guide pairs of X, Y, and Z are subjected to ultrasonic quenching, precision grinding and scraping treatment, combined with forced lubrication, which improves the accuracy and extends the service life of the machine tool.

3. Daily maintenance points of the universal lifting table milling machine

- Regularly check the lubrication of the guide rails and keep the lubricating oil clean

- Replace the grease of the spindle bearing every 2000 hours

- The worktable lead screw needs to adjust the clearance regularly

- The electrical system is dust-proof and moisture-proof

- Rust-proof treatment should be done when it is not used for a long time

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى