Don't hesitate to contact when you need us!

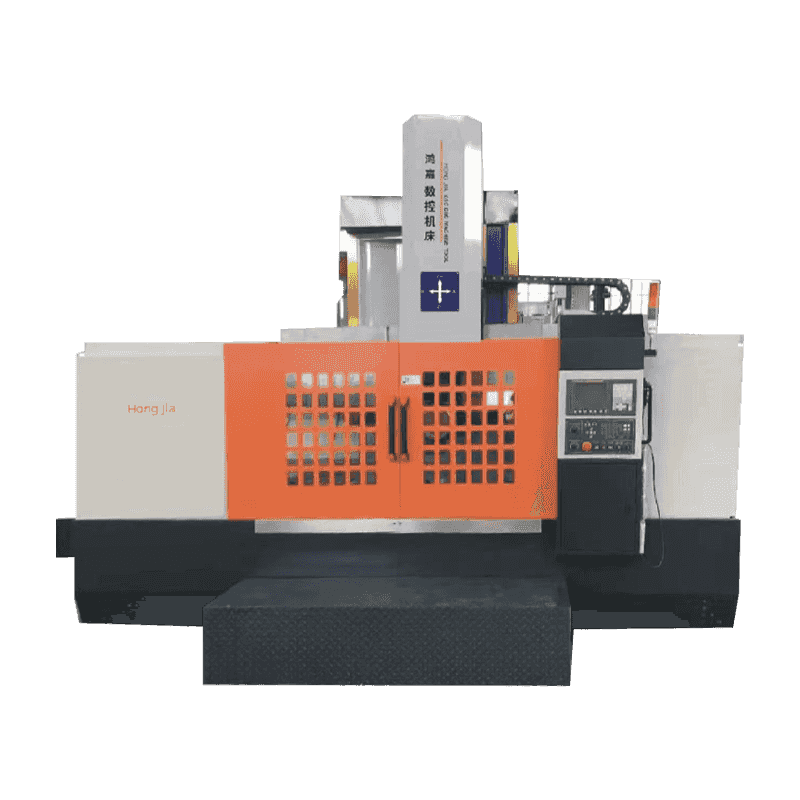

Maintenance points for high-power CNC horizontal lathes High-Power CNC Horizontal Lathe

2025.06.23

2025.06.23

Industry News

Industry News

- Daily maintenance measures

Guide rail and lubrication system maintenance——

Guide rail and lubrication system maintenance——

Cleaning and lubrication: The guide rail surface of the high-power CNC horizontal lathe needs to be cleaned and lubricated every day to avoid wear caused by accumulation of iron chips. If equipped with an automatic lubrication system, it is necessary to check the oil volume and clean the oil circuit regularly to ensure that the oil pump starts and stops normally.

Lubricant selection: It is recommended to use high-viscosity lubricants for high-power machine tools and replace them regularly (such as replacing 60L hydraulic oil every quarter).

Cooling and hydraulic system inspection——

Coolant management: Check the liquid level and cleanliness, replenish or replace in time to prevent impurities from affecting the heat dissipation effect; the hydraulic system needs to monitor whether the oil pressure is stable (normal range of the pressure gauge ±10%) and check for pipeline leaks.

Filter cleaning: Regularly clean the air duct filter of the cooling system of the high-power CNC horizontal lathe to avoid dust blockage and poor heat dissipation.Spindle and transmission parts——

Spindle drive belt: Check the tightness. If it is too loose, it will slip easily. If it is too tight, it will increase the bearing load. It is recommended to check high-power machine tools once a week.

Guide rail strip adjustment: Regularly adjust the gap between the strips to ensure processing accuracy and reduce mechanical wear.

2. Regular inspection and special maintenance

Electrical system maintenance——

Electrical cabinet inspection: Clean the dust in the electrical cabinet, check the operating status of the cooling fan, and prevent electronic components from overheating; regularly replace the memory battery.

Grounding and power supply: Ensure that the protective grounding resistance meets the standard, and the power supply voltage fluctuation does not exceed ±10%. It is recommended to equip a voltage stabilizer.

Key mechanical parts——

Ball screw and bearing: Check the axial clearance of the screw nut pair, and use the gasket or nut adjustment method to eliminate the idle travel; the bearing needs to be lubricated regularly (such as grease-lubricated spindles need to be filled for life).

Turret and chuck: The power turret needs to check the indexing accuracy and hydraulic clamping force; add grease to the chuck daily, and clean the chips regularly in the oil cylinder.

Hydraulic and pneumatic systems - Oil pumps and filters: Monitor oil pump noise. Abnormalities may be caused by low oil tank level or filter blockage. Clean or replace hydraulic/pneumatic filters every six months.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى