Don't hesitate to contact when you need us!

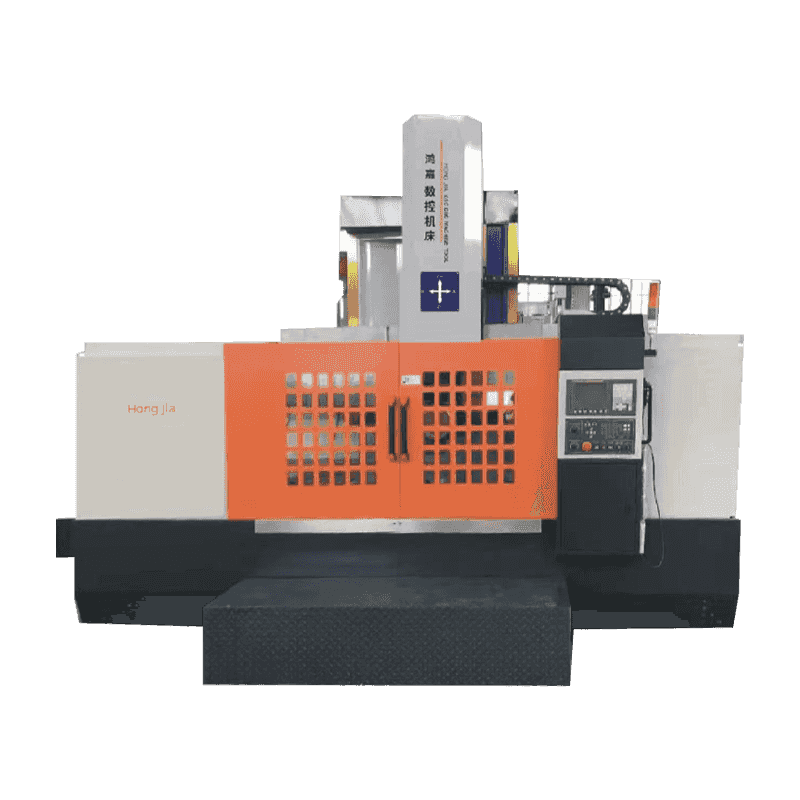

High-Rigidity Precision Tool: A Comprehensive Analysis of CNC Vertical Lathes

2025.10.17

2025.10.17

Industry News

Industry News

Content

1. Advantages of CNC Vertical Lathe

The core design concept of CNC vertical lathe is to pursue the ultimate rigidity and stability. The X-axis of the machine tool innovatively adopts an over-positioning dynamic column structure and is equipped with three high-rigidity guide rails, combined with large-section high-quality bearings, to build a solid mechanical foundation. This design gives the machine tool excellent shock absorption performance and extremely high rigidity, which can not only easily cope with high-load rough processing, but also ensure excellent precision during fine processing.

Powerful processing capabilities: It can perform high-speed turning of internal and external cylindrical surfaces, conical surfaces, arcs and various complex rotary surfaces on various ferrous metals, non-ferrous metals and some non-metallic parts, achieving perfect coverage from rough processing to fine processing.

2. Structure and Design

(1). Overall design

The CNC vertical lathe adopts mechatronic design, with a compact structure, reasonable layout and modern and beautiful appearance. Safety and environmental protection are equally important: Equipped with fully enclosed protective devices, they effectively prevent coolant and chip splashing. A rear-mounted automatic chip removal system and hydraulic chuck automatic clamping function significantly enhance automation and operational safety.

Scientific Optimization: The entire machine is optimized using finite element analysis to ensure reliable performance, optimal dynamic rigidity, and smooth operation.

(2).Core Components

Heavy-Duty Base: The base utilizes a high-strength, monolithic box-type structure. The internal rib layout is precisely calculated using finite element analysis, and the material is high-density cast iron. This combination gives the base exceptional strength and excellent vibration absorption, providing a rock-solid foundation for the entire machine.

Sturdy Column: The rectangular column stands majestically atop the base. The carriage is secured to the column via three linear guides, one of which is a key guide supported at the bottom. This creates a stable three-point support structure, enabling the machine to withstand heavy cutting loads and maintain machining accuracy over time.

High-Performance Spindle: The spindle is directly driven by a high-performance servo motor. The core bearings utilize imported high-precision double-row cylindrical roller bearings and double-direction angular contact ball bearings, while the rear support also utilizes high-precision double-row cylindrical roller bearings. This precision bearing system fully meets the demands of significant axial and radial cutting forces.

Powerful Toolholder and Feed System: The CNC vertical lathe is equipped with an imported high-performance horizontal hydraulic toolholder, which not only offers high torque output and reliability, but also features a compact structure, effectively reducing interference during machining.

Precision Drive: The X and Z axis feeds are driven by servo motors and equipped with C3-grade, large-diameter precision ball screws. The preloaded design of the screws eliminates transmission backlash, ensuring high rigidity and positioning accuracy.

High-Speed Guides: All axis guides utilize high-load capacity, friction-resistant roller guides, designed for efficient and precise heavy-duty cutting.

3. Typical Application Scenarios

CNC vertical lathes are key production equipment for the following industries and parts:

Automotive: Engine flywheels, brake drums, wheel hubs, reducer housings, etc.

Wind Power: Processing large ring-shaped parts such as wind turbine bases, gearbox end covers, and other covers.

Heavy Machinery: Various large flanges, end covers, valves, etc.

Aerospace: Rocket engine end covers, turbine discs, etc.

General Machinery: Large bearing seats, pump casings, mold bases, etc.

Steel and Metallurgy: Rolling mill arches, large gears, etc.

Power Equipment: Ultra-large components such as upper and lower rings for hydraulic and steam turbines and shield machine cutterheads.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى