Don't hesitate to contact when you need us!

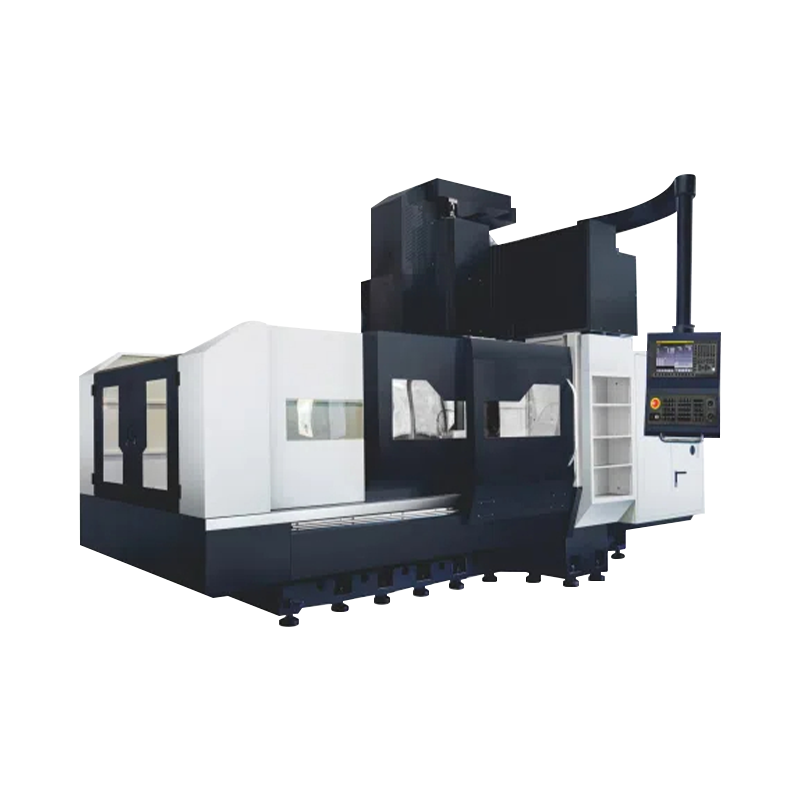

Why is CNC Vertical Lathe one of the core equipment of smart factory?

2025.06.17

2025.06.17

Industry News

Industry News

- Technical features of CNC Vertical Lathe

- High-precision processing capability

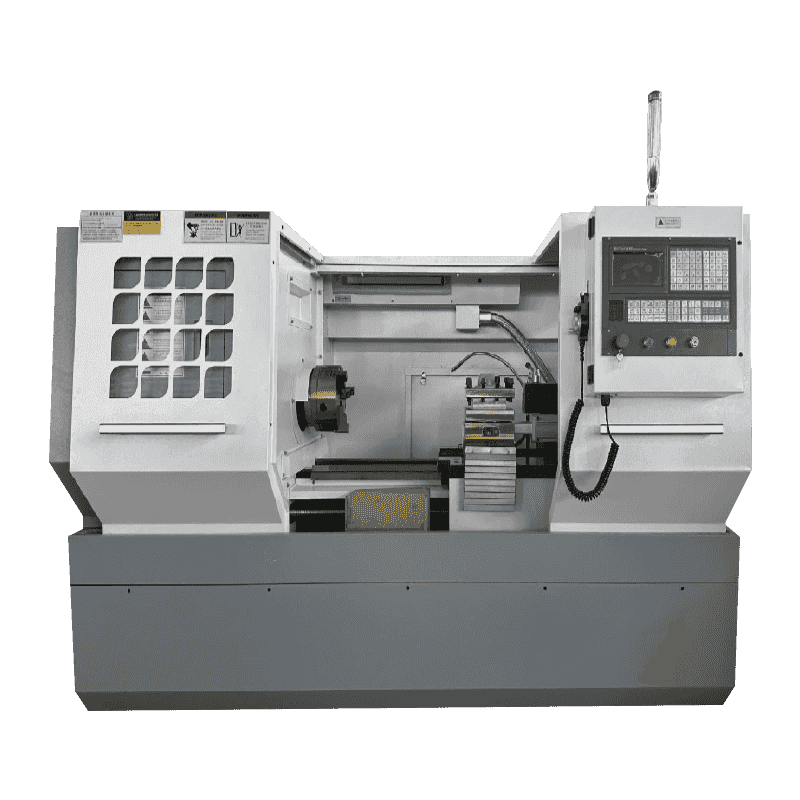

CNC vertical lathe is a high-rigidity and cost-effective machine tool. The CNC vertical lathe adopts a positioning column structure, equipped with three guide rails, and with a larger bearing section, so that the machine tool has high rigidity and shock absorption, which can ensure high-precision and high-load cutting. The machine adopts imported high-performance horizontal hydraulic tool holder, which has large cutting force, high reliability and small processing interference.

- High degree of automation

The CNC vertical lathe adopts mechatronics design, compact structure, reasonable layout and beautiful shape. The machine is equipped with a closed protective device, rear automatic chip removal, and hydraulic power chuck automatic clamping. The whole machine adopts finite element optimization design, reliable performance, good dynamic rigidity and smooth operation. The base of the machine is an integral box-type base, and the rib layout is optimized by finite element design, which makes the machine tool have good rigidity. The material is high-density cast iron, high strength and good vibration absorption performance. Reduced manual intervention and automated processing. This feature enables it to be seamlessly integrated into the automated production process of smart factories.

2. Application of CNC vertical lathes in smart factories

- Basic unit of intelligent manufacturing

In smart factories, CNC vertical lathes, as basic processing units, are interconnected with other equipment and systems through the industrial Internet to achieve data sharing and collaborative production. Its processing data can be uploaded to the factory system in real time to provide a basis for production decisions.

- Executor of digital production

CNC vertical lathes can directly execute the processing programs generated by digital design and transform digital models into actual products. They are the key link between product design and physical manufacturing. This digital production capability is one of the core features of smart factories.

- Key nodes of intelligent optimization

Modern CNC vertical lathes are equipped with various sensors, which can monitor processing status, tool wear and other conditions in real time, and optimize processing parameters through big data analysis, realize predictive maintenance and process optimization, and improve overall production efficiency.

3. Advantages of CNC vertical lathes in promoting the development of smart factories

- Improve production efficiency

The high-speed cutting capability and automation characteristics of CNC vertical lathes significantly improve production efficiency. In the smart factory environment, through the coordinated optimization with other equipment, the production cycle can be further shortened and the equipment utilization rate can be improved.

- Ensure product quality

The processing consistency and stability of CNC vertical lathes are much higher than those of traditional equipment. With the online detection system, it can ensure the consistency of product quality and reduce the scrap rate, which is an important guarantee for the pursuit of "zero defect" production in smart factories.

- Reduce production costs

Although the initial investment is high, the automated production of CNC vertical lathes reduces labor costs, and its high-precision processing reduces material waste. In the long run, it significantly reduces the overall production cost, which meets the economic requirements of smart factories.

Achieve green manufacturing

Modern CNC vertical lathes adopt energy-saving design, and optimizing cutting parameters can reduce energy consumption. With the energy management system of smart factories, a more environmentally friendly and sustainable production model can be achieved.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى