Don't hesitate to contact when you need us!

Why do your motorcycle parts need a long turret CNC lathe?

2025.11.12

2025.11.12

Industry News

Industry News

In the fast-paced world of motorcycles, the precision, strength, and consistency of every component directly impact riding performance and safety. From precision engine cylinder heads to complex transmission gears, the manufacturing of these critical components relies heavily on a powerful core piece of equipment—the turret CNC lathe. It's not just a machine; it's a winning strategy for enhancing competitiveness and conquering demanding processes.

1. Function: Why is it a key component in motorcycle parts processing?

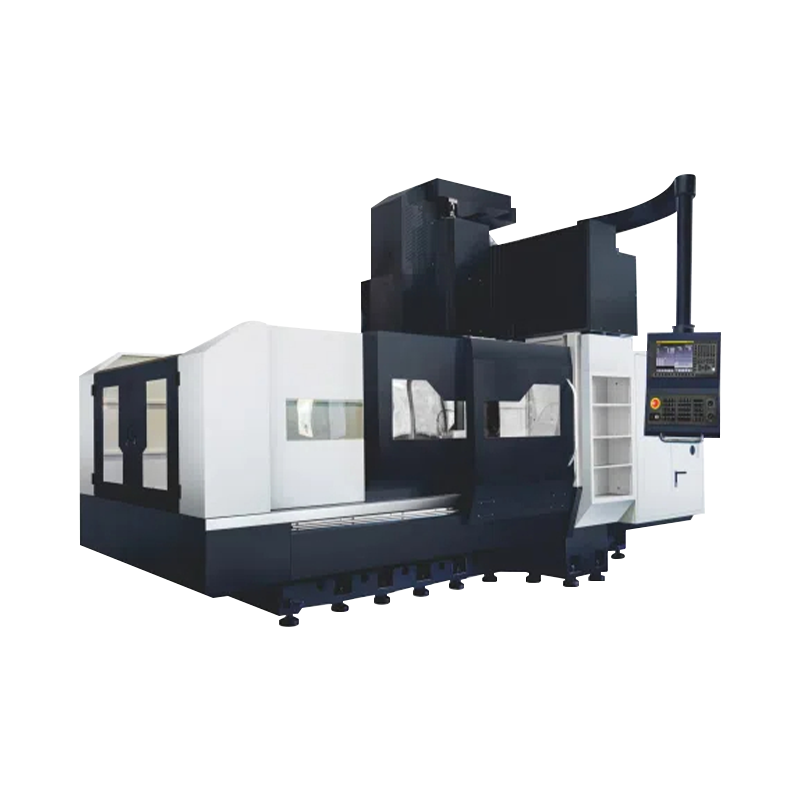

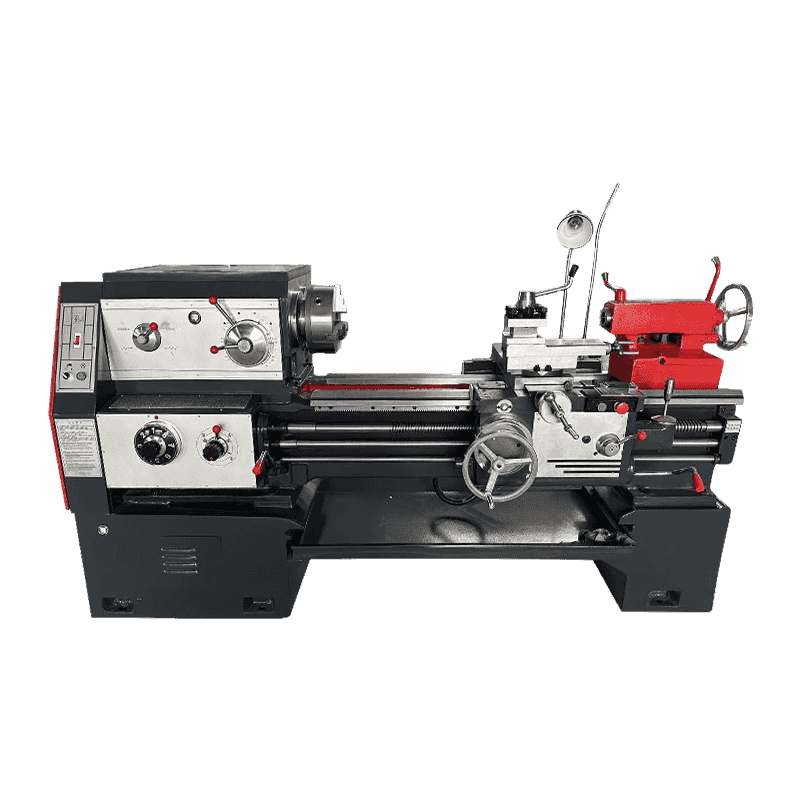

The core advantage of the turret CNC lathe lies in its "long turret" design. Compared to traditional turrets, it boasts more tool positions (typically up to 12 or more), acting like a master mechanic carrying a complete tool library.

For motorcycle parts processing, this means: Complex parts, completed in a single setup: Motorcycle parts such as brake caliper bodies and shock absorber connectors often require multiple processes including turning, milling, drilling, and tapping. The turret CNC lathe allows you to install over a dozen different types of tools at once. Workpieces can be clamped in a single setup, completing all machining operations and completely eliminating the cumulative errors caused by multiple clampings, ensuring extremely high coaxiality and positional accuracy.

Efficiency Multiplied, Decisive Production Cycle: When mass-producing standard parts such as screws, bushings, and connecting rods, the long turret can pre-load roughing tools, finishing tools, grooving tools, threading tools, etc. Automatic program recall and seamless switching significantly reduce tool change waiting time during machining, allowing your production line to output continuously and efficiently, like a motorcycle engine.

Effortless Handling of Special Materials: Motorcycle parts often use materials such as alloy steel, aluminum alloy, and titanium alloy. The long turret's strong rigidity and multi-tool position capability allow you to easily configure dedicated tools for different materials, handling both high-intensity cutting and high-finish finishing with ease.

2. Advantages and Features: Performance Tailor-Made for Motorcycle Parts Manufacturing

High Rigidity Structure and Precision Stability: The turret CNC lathe is designed for continuous heavy cutting, ensuring that the machine tool does not deform when machining hard motorcycle gears or crankshafts, maintaining micron-level machining accuracy over a long period.

Powerful Cooling and Chip Removal System: Cutting motorcycle parts generates a large amount of metal chips. An efficient chip removal system and coolant management quickly flush chips away from the machining area, preventing them from entangled in the workpiece or tool, ensuring surface finish, and protecting the machine tool guideways and lead screws.

Intelligent and Automated Compatibility: Modern turret CNC lathes easily integrate with automated loading and unloading systems (robots or feeders), easily creating unmanned "lights-out factories," making them ideal for handling large-scale, multi-batch motorcycle parts orders.

3.Post-Maintenance Cleaning and Maintenance

Proper maintenance of turret CNC lathes is key to ensuring long-term stable operation and efficiency:

Daily Cleaning is Essential: Turret Tool Head: After each day's machining, be sure to use an air gun to clean the chips and coolant from the turret taper hole and tool holder surface to prevent impurities from affecting tool changing accuracy and locking force.

Guideways and Lead Screws: Remove all chips from the guideways and check and replenish lubricating oil. This is an essential step to ensure the machine tool's movement accuracy and lifespan. Inside the protective cover: Regularly clean accumulated chips inside the protective cover to prevent clogging and corrosion.

Regular maintenance for longevity:

Tool system inspection: Regularly check the repeatability and tool tension of the turret CNC lathe to ensure every tool is stable and accurate.

Cooling system maintenance: Regularly replace or filter the coolant, and clean oil and metal sludge from the water tank to prevent bacterial growth and nozzle clogging.

Professional inspection: Follow the manufacturer's recommendations to regularly perform professional leveling, parameter backup, and system upgrades to prevent problems before they occur.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى