Don't hesitate to contact when you need us!

What are the key parameters to pay attention to when choosing a double column machining centre?

2025.06.12

2025.06.12

Industry News

Industry News

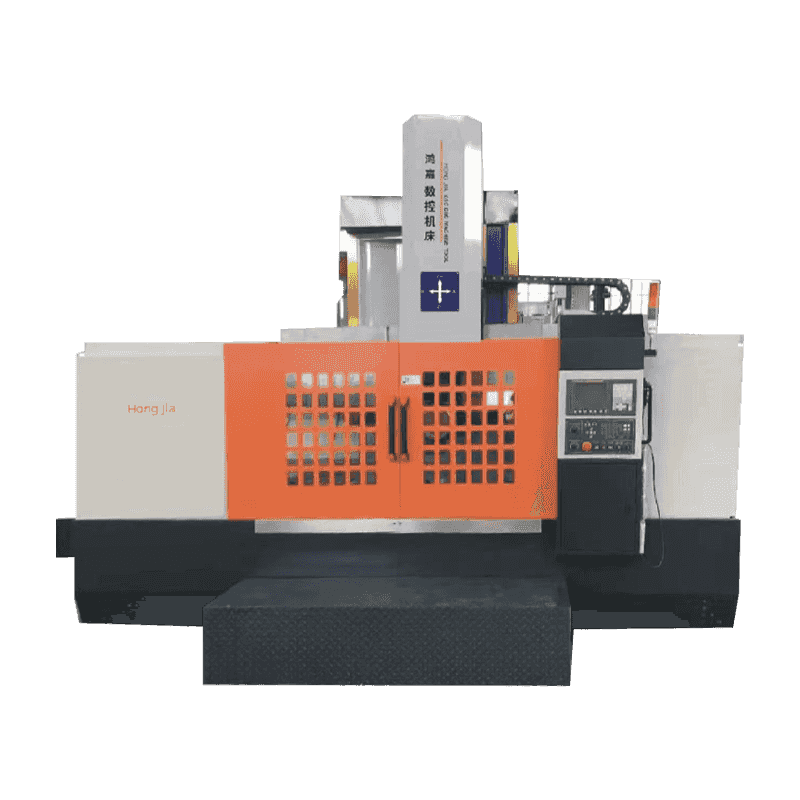

1. Basic Specifications

The travel range is the basic parameter indicator of the double column machining centre, which determines the size of the workpiece that the equipment can handle. The travel of the three axes of X, Y, and Z is 20%-30% larger than the size of the workpiece to be processed, which can accommodate fixtures and tools. Machining large wind turbine gearbox housings usually requires a double column machining centre with an X-axis travel of more than 6000mm, while mold processing may only require a travel of about 3000mm to meet most needs. In addition, the size and load-bearing capacity of the worktable are also crucial. The worktable should be 15%-20% larger than the typical workpiece size, and the load-bearing capacity needs to consider the combined effects of the workpiece blank weight, fixture weight, and cutting force.

Structural design parameters affect the rigidity and stability of the machine tool. The double column machining centre adopts a symmetrical column structure. The column spacing determines the span and rigidity of the beam. It should usually be ensured that the column spacing can accommodate the largest workpiece and leave enough safety space. The choice of bed material is also critical. High-quality double-column machining centers mostly use mineral composite beds or high-quality cast iron, and ensure high rigidity and shock absorption performance through finite element optimization design.

The power configuration reflects the processing potential of the machine tool. The spindle motor power needs to be selected according to the material removal rate of typical workpieces. Rough machining of aluminum alloys usually requires 15-25kW, while high-strength steel machining may require a power configuration of more than 30kW. The feed drive power is also not to be ignored. High-power drive can ensure a stable feed speed during heavy cutting and avoid "creeping". It is worth noting that the motor torque characteristics can better reflect the actual processing capacity than the simple power index, especially the low-speed high-torque capacity is particularly critical for difficult-to-process materials.

2. Accuracy and repeat positioning

Positioning accuracy and repeat positioning accuracy are direct parameters for measuring the accuracy of double-column machining centers. According to the standard, the positioning accuracy of ordinary double-column machining centers should reach 0.015-0.025mm/full length, and the repeat positioning accuracy should reach 0.008-0.012mm. The requirements for more precise equipment are higher. It should be noted that the accuracy standards adopted by different manufacturers may be different. When comparing parameters, the consistency of the test standards should be confirmed.

Geometric accuracy is the basis of machine tool accuracy. Although it does not often appear in the technical parameter table, the supplier should be required to provide acceptance data. Key geometric accuracy indicators include: verticality between the column and the worktable (usually ≤0.01mm/300mm), parallelism between the beam and the worktable (≤0.015mm/full length), spindle radial runout (≤0.002mm), etc. Long-term accuracy retention is also important, which can be evaluated by examining the guide type (such as roller guides are more suitable for heavy loads than ball guides), lead screw pre-stretching technology and heat treatment processes for key components.

3. Spindle system and tool management

The spindle unit is an important component of the double-column machining center, and its parameter selection is also relatively important. The speed range should be determined according to the processing requirements: the processing of non-ferrous metals such as aluminum alloys requires a high speed of 15000-24000r/min, while the processing of steel and cast iron usually uses a medium speed range of 4000-8000r/min. The tool magazine system directly affects the processing efficiency and degree of automation. The capacity of the chain tool magazine is usually 40-120 pieces, which should be reasonably selected according to the degree of process concentration to avoid management difficulties caused by excessive capacity. Tool change time is a key efficiency indicator. The tool change time of a general disc tool magazine is 3-5 seconds, while a large chain tool magazine may take 8-15 seconds. Data shows that automatic tool changer failures account for about 50% of the total failures of the machining center, so designs with simple structure and high reliability should be given priority.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى