Don't hesitate to contact when you need us!

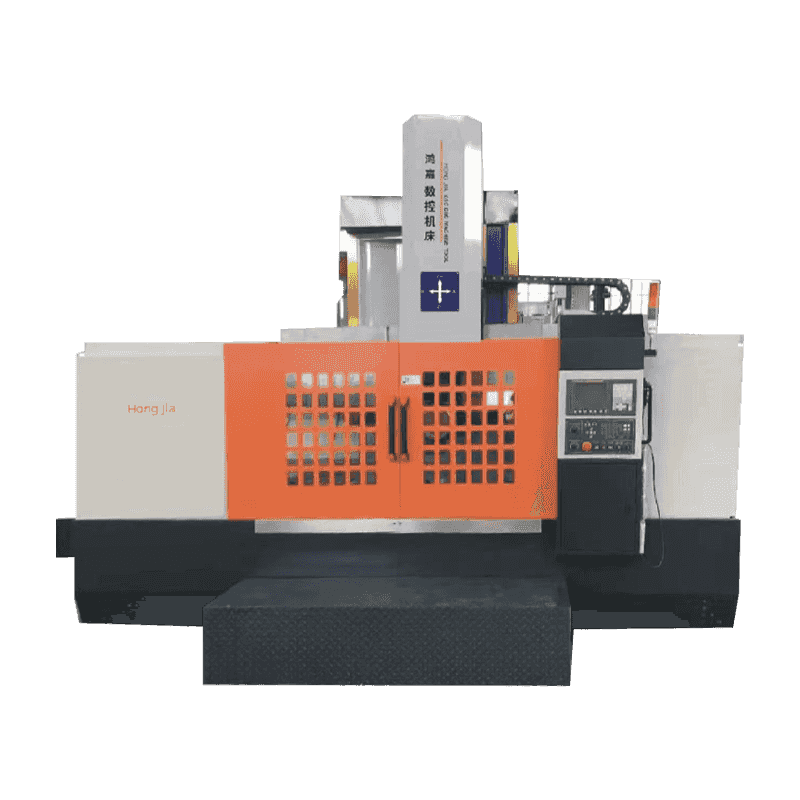

What is a Double Column Machining Center?

2025.08.13

2025.08.13

Industry News

Industry News

Content

1. Basic Introduction to Double-Column Machining Centers

A double-column machining center is a large, high-precision, high-efficiency CNC machine tool primarily used for machining large or heavy workpieces. Its name comes from its unique structural design—two columns supporting a horizontal beam (a gantry structure), creating a highly rigid and stable frame suitable for heavy-duty cutting and high-precision machining.

Core Features of a Double-Column Machining Center

Double-Column Gantry Structure

Comprising two columns and a top horizontal beam, the double-column gantry structure provides a rigid frame with a movable or fixed worktable located underneath, making it suitable for machining large spans and heavy loads.

Compared to single-column machines, the double-column design offers greater torsional resistance, reduces cutting vibration, and ensures machining accuracy.

Large Working Range

The worktable is typically wide (up to several meters), allowing it to handle large workpieces such as aerospace components, wind turbine equipment, molds, and machine tool beds.

High Rigidity and Stability

Using cast iron or welded steel construction, it offers excellent vibration absorption and is suitable for heavy-duty cutting (such as rough machining of steel and titanium alloys). Some models are equipped with a temperature compensation system to minimize the impact of thermal deformation on precision.

Multi-Axis Linkage Capability

Common configurations include 3-axis (X/Y/Z), 4-axis (with a rotary table), or 5-axis (multi-angle machining), enabling machining of complex curved surfaces (such as impellers and propellers).

High Precision and Automation

Equipped with precision roller guides and a servo drive system, positioning accuracy can reach within ±0.005mm.

Optional automatic tool changers (ATC) and workpiece measurement probes enhance automation.

Typical Applications

Energy Industry: Wind turbine gearboxes and turbine blades.

Aerospace: Aircraft frames and engine components.

Mold Manufacturing: Large injection molds and die-casting molds.

Rail Transportation: Bogies and vehicle body structures.

Heavy Machinery: Mining equipment and hydraulic press frames.

Differences from a single-column machining center

|

Features |

Double Column Machining Center |

Single Column Machining Center |

|

Structure |

Gantry type, dual-column support |

Cantilever type, single-column support |

|

Rigidity |

Higher, suitable for heavy cutting |

Weaker, suitable for small and medium-sized workpieces |

|

Machining range |

Extra-large workpieces (length and width) |

Medium-sized workpieces |

|

Cost |

High (complex structure) |

Relatively low |

2. Common Problems and Solutions for Double-Column Machining Centers

- Decreased Machining Accuracy

Possible Causes:

Thermal deformation of the machine: Prolonged operation causes the spindle, guideways, or lead screw to heat up, affecting positioning accuracy.

Mechanical wear: Wear on key components such as the ball screw, guideways, and bearings can cause backlash or unstable movement.

Unstable foundation: The machine vibrates or settles, disrupting levelness.

Excessive cutting forces: Improper tooling or cutting parameters can cause vibration or deformation.

Solutions:

Control temperature:

Use the machine warm-up procedure (run at low speed for 10-15 minutes).

Install a cooling system (spindle oil cooler, guideway lubrication thermostat).

Regular Maintenance:

Check lead screw backlash and adjust or replace if necessary.

Regularly calibrate the machine level (using a precision level).

Optimize cutting parameters: Reduce cutting depth/feed rate to avoid overloading.

- Spindle Failure

Common Problems:

Spindle overheating: Poor bearing lubrication or insufficient cooling.

Spindle vibration/noise: Tool imbalance, bearing damage, or spindle dynamic balancing failure.

Spindle failure: Driver alarm, motor failure, or tool clamping mechanism stuck.

Solutions:

Lubrication and Cooling:

Check the spindle oil-air lubrication system for proper function (oil volume and air pressure).

Ensure adequate coolant flow (especially when machining deep holes).

Dynamic Balancing:

Dynamic balancing after tool installation (especially during high-speed cutting).

Regularly check the spindle bearing condition and replace worn parts.

Troubleshooting Electrical Problems:

Check the driver alarm code, reset it, and restart. Frequent alarms require repair of the motor or encoder.

- Guideway and Screw Wear

Symptoms:

Striations or tool marks appear on the machined surface.

Unusual noise or increased resistance during machine movement.

Positioning accuracy is out of tolerance (e.g., repeatability > 0.02mm).

Causes and Solutions:

Insufficient Lubrication:

Check the automatic lubrication pump oil circuit for blockage and switch to high-viscosity guideway oil.

Protection Failure:

Clean chips from the guideway guard to prevent hard particles from scratching the guideway surface.

Preload Adjustment:

Readjust the ball screw preload. Overtightening increases wear, while overloosening causes backlash.

- Worktable Deformation or Vibration

Common Scenarios:

The worktable sinks or vibrates when machining heavy workpieces (such as large molds).

Insecure workpiece clamping causes shifting.

Solutions:

Increase Support:

Use auxiliary support feet or blocks to distribute the weight of the workpiece.

Select a high-rigidity fixture (such as a hydraulic fixture).

Vibration Reduction Measures:

Install anti-vibration pads (such as polyurethane) between the workpiece and the worktable.

Reduce the feed rate or use step cutting.

- Coolant and Chip Removal Issues

Problem Symptoms:

Coolant spray blockage, resulting in poor heat dissipation in the machining area.

Chips accumulate, scratching the workpiece or obstructing guideway movement.

Solution:

Filtration system upgrade:

Use a magnetic separator and paper belt filter combination to keep the coolant clean.

Automated chip removal:

Install a chain-type chip conveyor or spiral chip conveyor and regularly clean the chip removal channel.

3. Double-column machining center FAQs

- Q1: What are the key points for daily maintenance of a double-column machining center?

A1:

Daily:

Check the lubricant/coolant levels.

Clean chips to prevent accumulation that could affect the guide rails/lead screw.

Weekly:

Clean the spindle taper (with a non-woven cloth and alcohol).

Check the air pressure (0.5-0.7 MPa).

Monthly:

Lubricate the guide rails/lead screw and remove any old grease.

Check the belt tension (if any).

- Q2: How do I determine if the guide rails or lead screws need to be replaced?

A2: Repair or replacement is required in the following situations:

Guide rails:

Surface scratches or rust.

Abnormal noise or noticeable increase in resistance during movement.

Lead screw:

Backlash > 0.02 mm (checked with a dial indicator).

Machining "streaks" or dimensional instability occurs.

- Q3: What should I do if the robot arm gets stuck during a tool change?

A3:

Emergency Solution:

In manual mode, press the "Tool Change Reset" button.

Use a wrench to gently push the manipulator (avoid forceful operation).

Fundamental Solution:

Check the toolholder pull pin for wear.

Adjust the ATC tool change position (PLC parameter modification required).

- Q4: How do I resolve the "Servo Overload" alarm in the CNC system?

A4:

Troubleshooting Steps:

Check for excessive cutting force (reduce feed rate).

Confirm that the motor cooling fan is functioning properly.

In-depth Inspection:

Measure the motor insulation resistance (use a multimeter to check for short circuits).

Check whether the coupling needs to be re-tightened.

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى